When you request a quote with China Manufacturing parts, your part is evaluated by our team of Manufacturing Engineers. China Manufacturing parts, Inc. will provide Design For Manufacturability (DFM) feedback throughout the quoting and ordering process to ensure your design is optimized for Injection Molding and that any quality risks or requirements deviations are discussed and acknowledged.

In order for China Manufacturing parts, Inc. to proceed with injection molding tooling, you must approve the feedback that is being shared with you. This ensures a common understanding of the requirements and expected outcomes.

Note: Powerpoint based DFM reports have been discontinued. For instructions on how to review and respond to an existing Powerpoint file, please refer to this Help Center article. |

Prefer to watch and learn? Jump to the video tutorial at the bottom of this page.

How to review your DFM reports

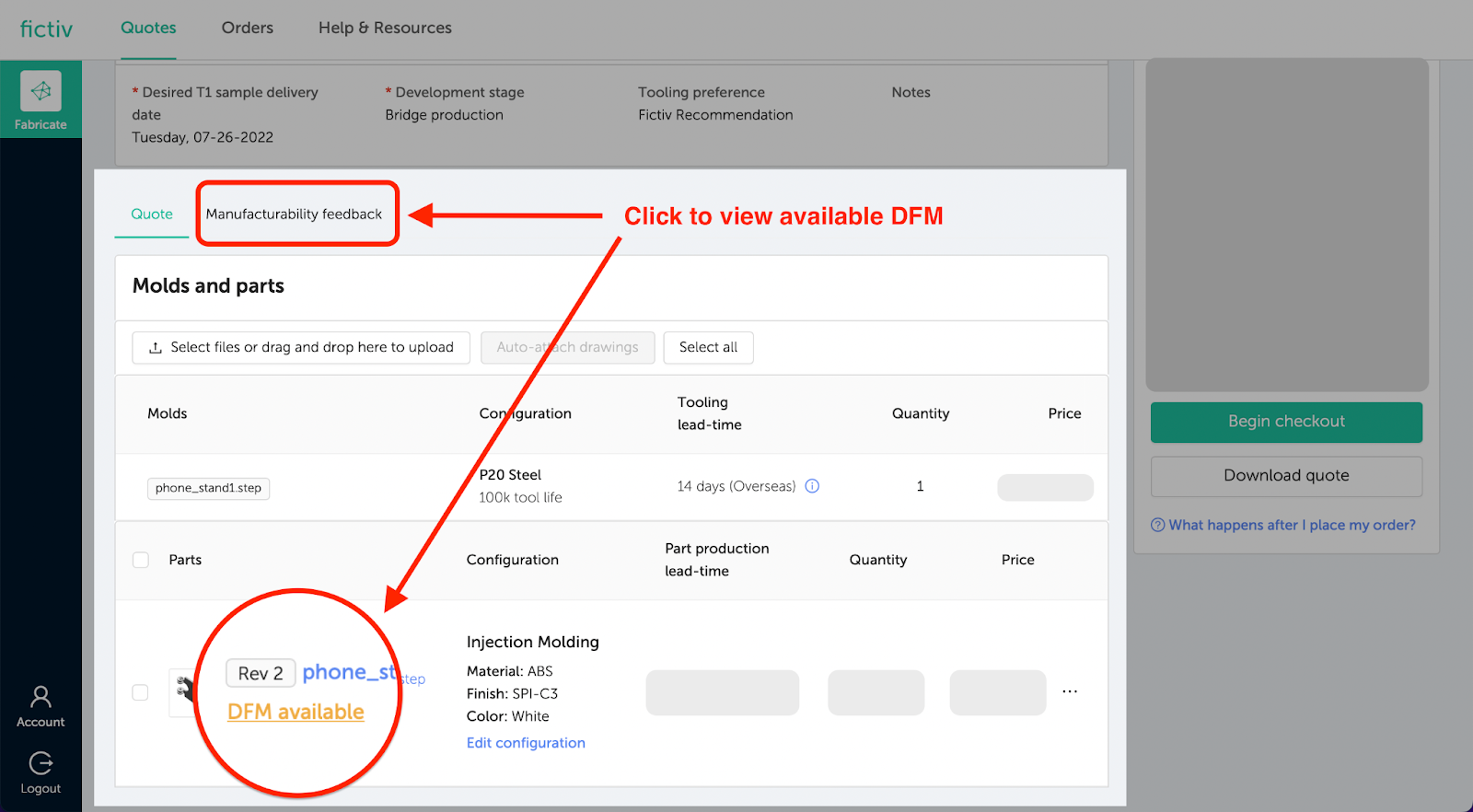

You will receive an email notification when new DFM reports are ready for your review and approval. When DFM reports are available for a part, an orange link will appear below your part and drawing file names. Click this link to view the DFM reports available for your part. You can also access your DFM reports by clicking the “Manufacturability feedback” tab above the Molds and parts section in your quote.

How to approve the DFM feedback

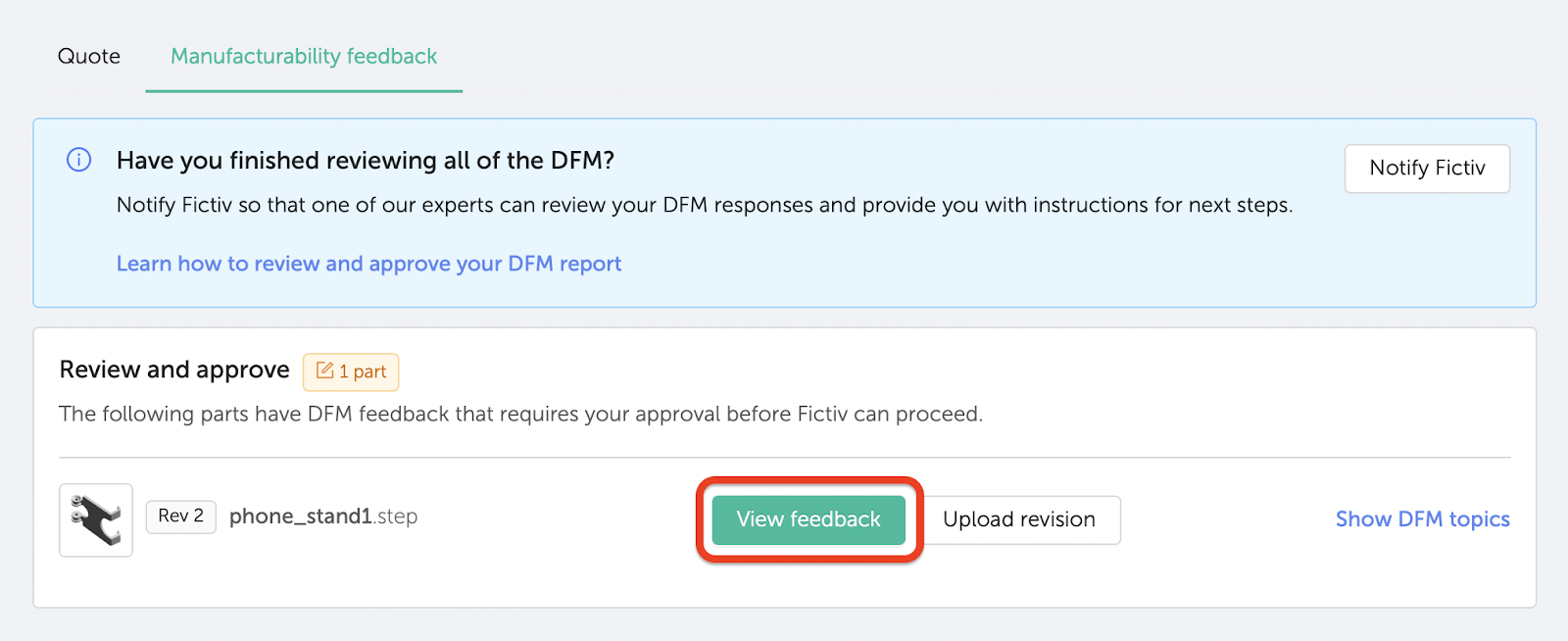

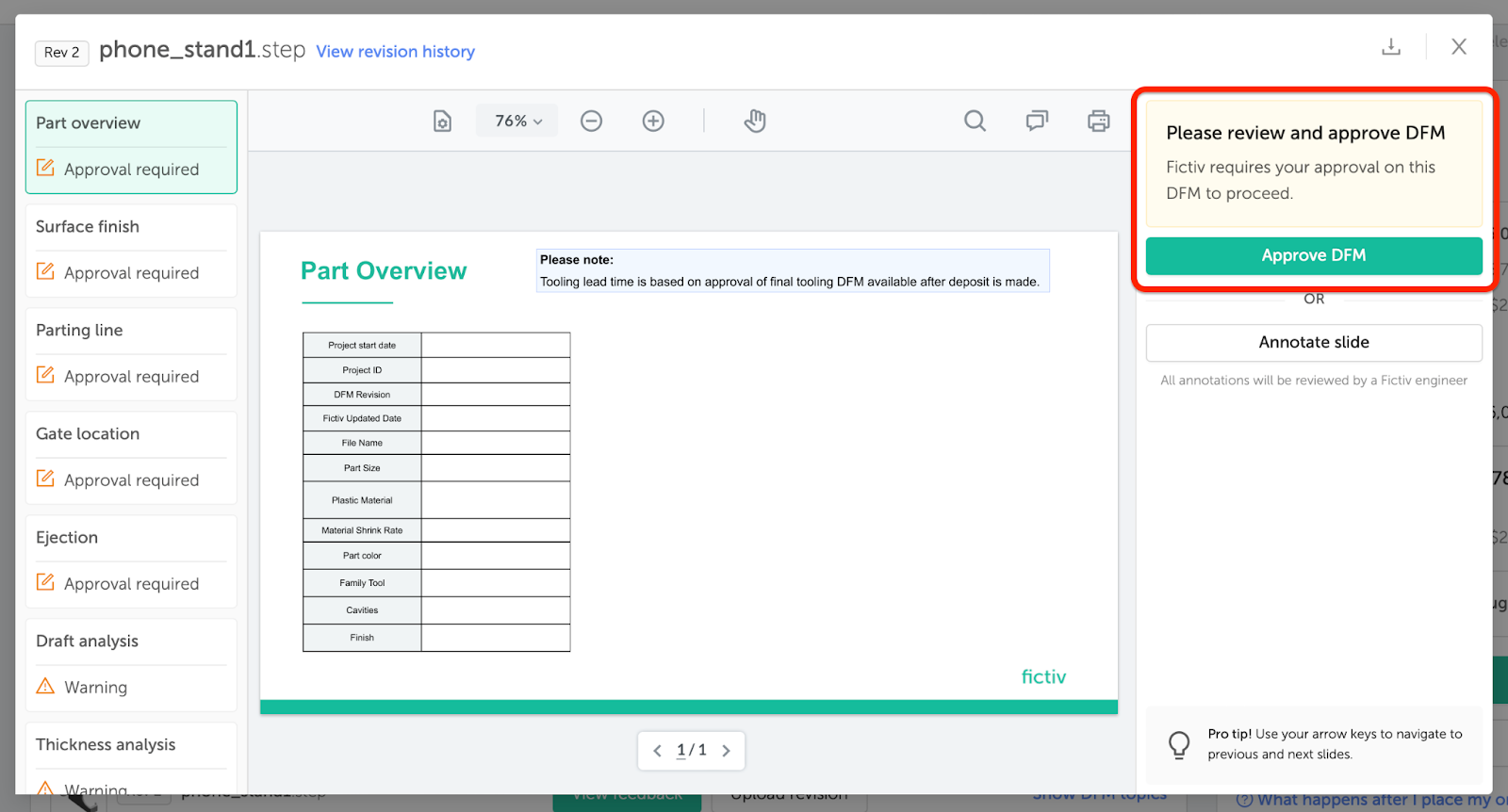

Depending on your part design, China Manufacturing parts, Inc. may provide a different manufacturability status for different topics such as Draft analysis or Thickness analysis. In order to proceed, China Manufacturing parts, Inc. requires a response on slides with an open status such as “Warning” or “Approval required”. To respond to the DFM feedback in your report, you can click on “View feedback” in the “Manufacturability feedback” tab of your quote or order details.

Pro tip! You can jump directly to a specific slide by clicking ‘Show DFM topics’ and clicking on a specific topic.

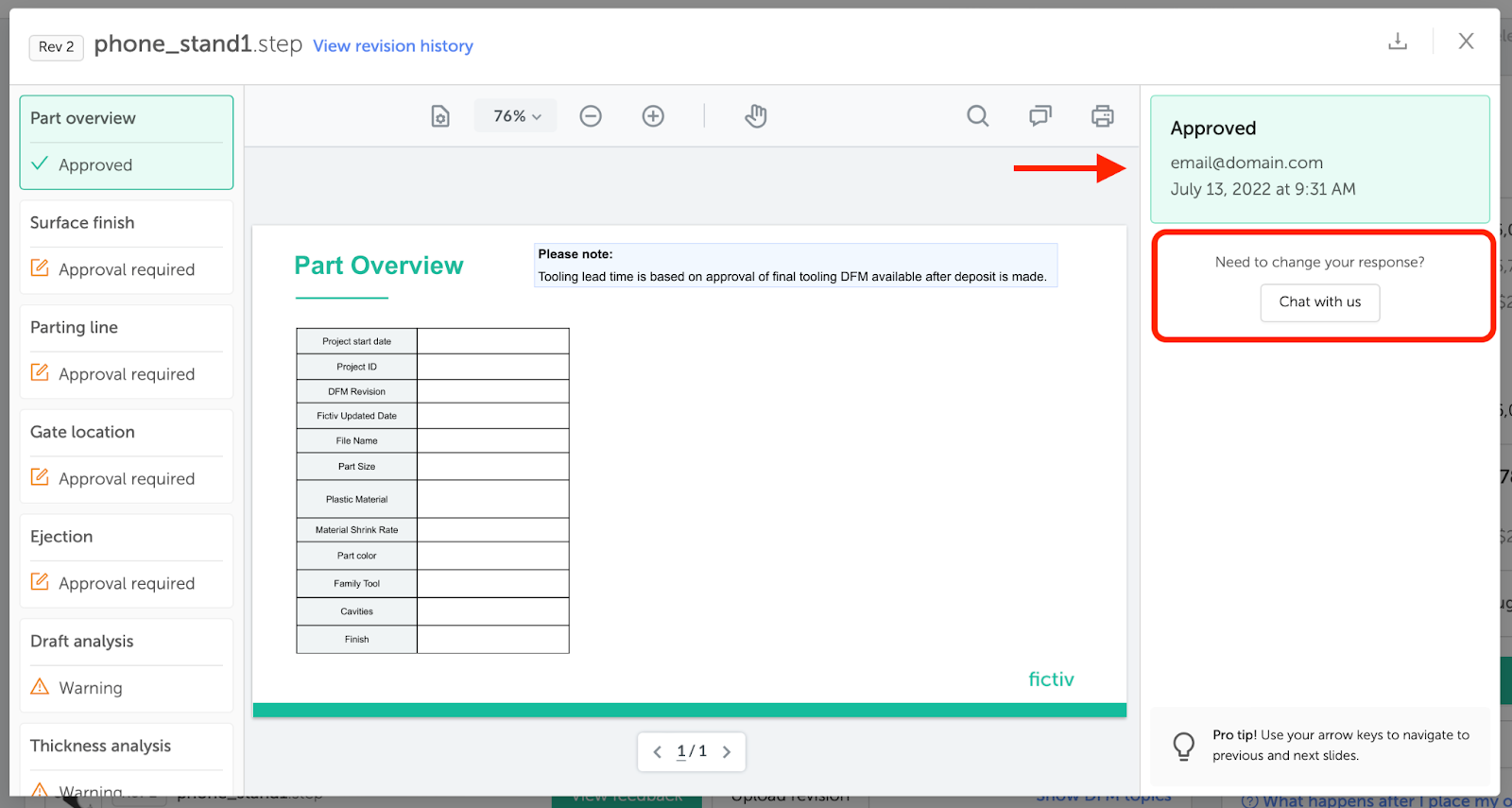

Note: Once you have responded to a slide, you will not be able to change your response directly on the China Manufacturing parts, Inc. platform. If for any reason, you need to change your response, please click ‘Chat with us’ to be directed to your China Manufacturing parts, Inc. account representative. They will be able to reset the status of your response.

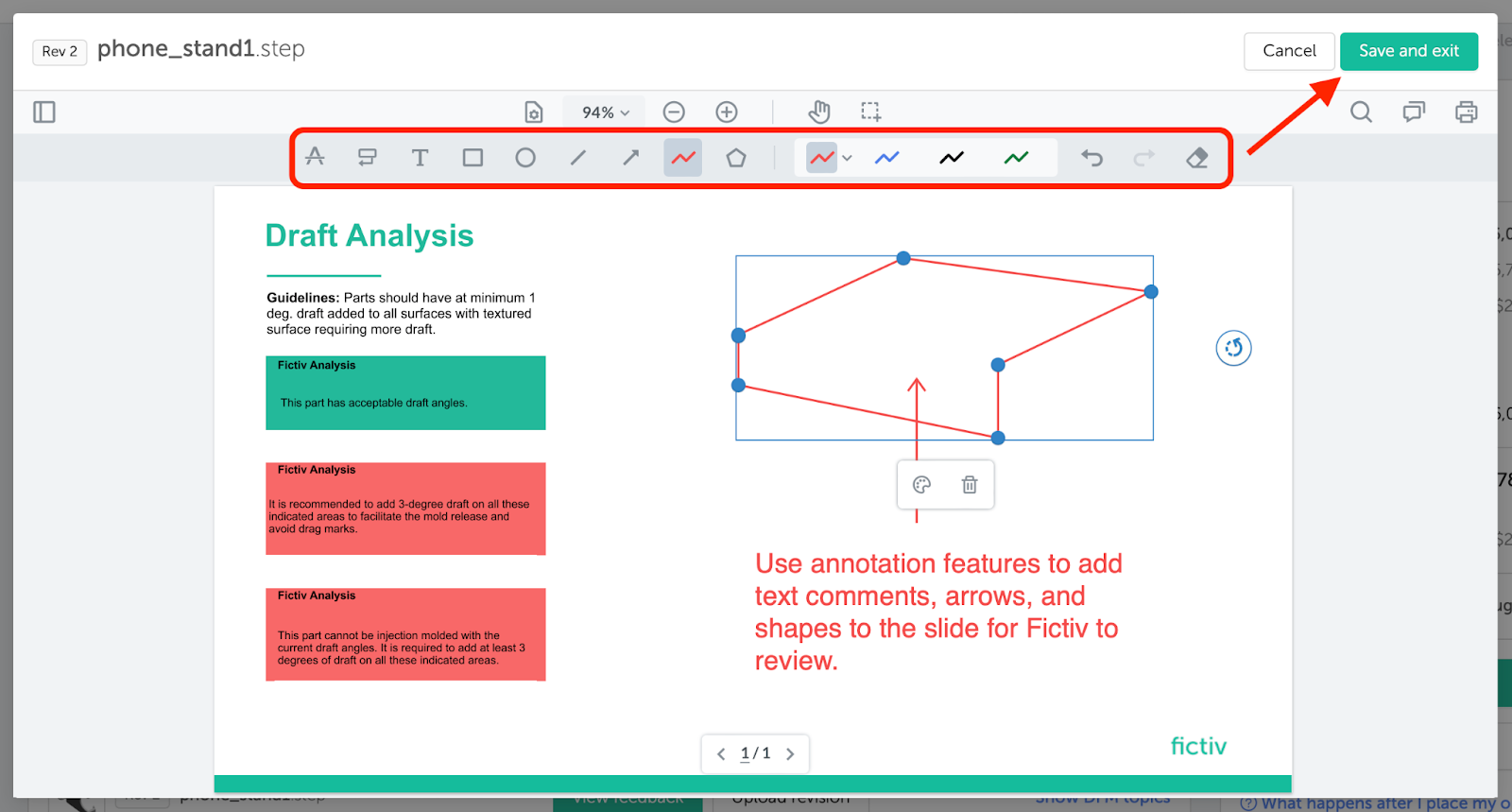

How to add annotate a slide in DFM report

Sometimes your design intent does not align with the DFM feedback you receive. This could be because of reasons such as the proposed parting line, ejector pin location, or required draft angle for assembly components. In cases where you need to respond to the DFM feedback and request a change or clarification to the proposed tooling design, you can click “Annotate slide” on all topics that have the status of “Revision required”, “Warning”, or “Approval required”.

After you have added your annotations to the slide, click ‘Save and exit’ to return to the DFM report. You will be able to edit these annotations until you notify China Manufacturing parts, Inc. that you have reviewed the DFM report. Once a China Manufacturing parts, Inc. engineer has reviewed your responses, they will reach out to you with instructions on how to proceed.

Please note that the annotation feature will not be available for any slides where you have already approved feedback or accepted any warnings.

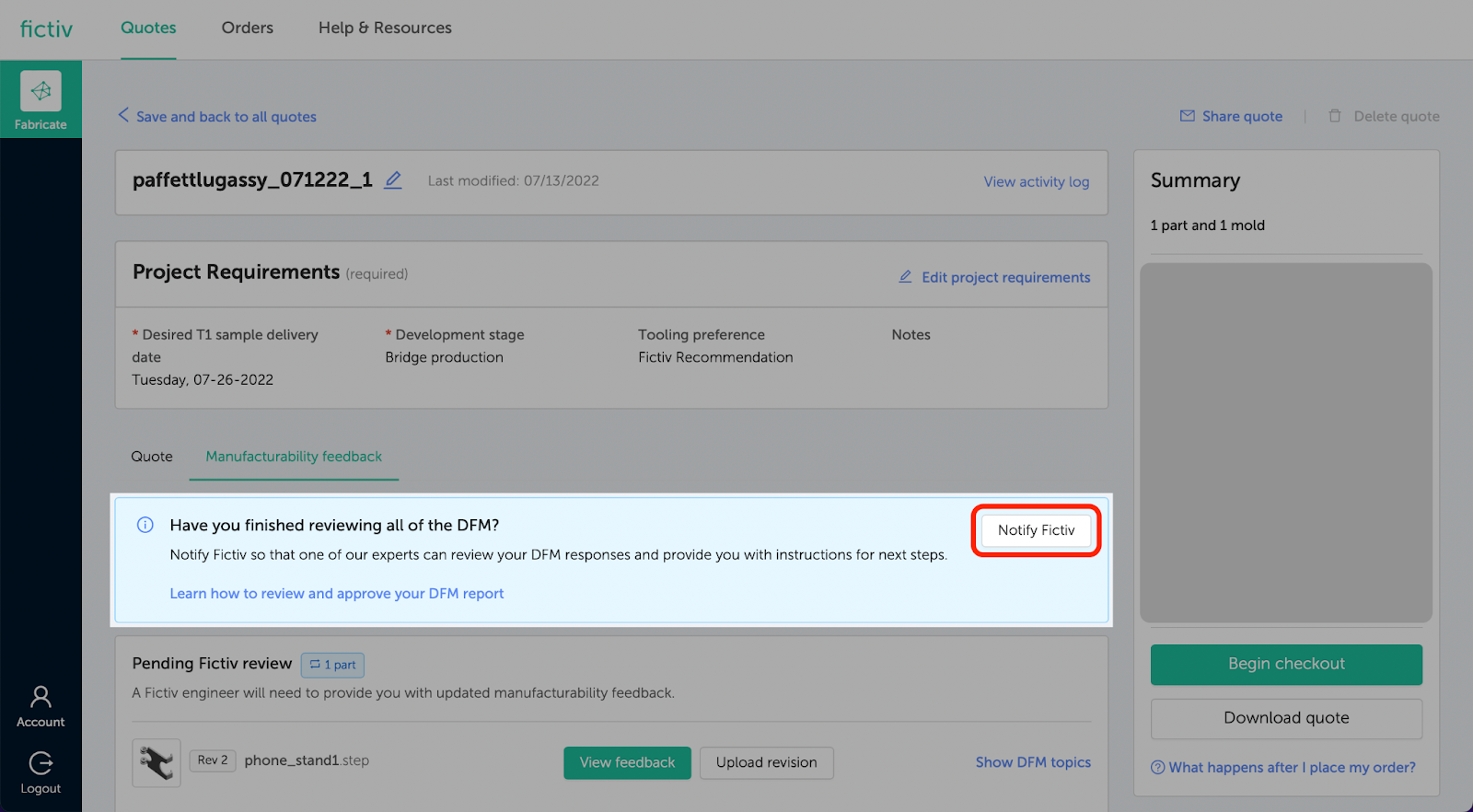

How to notify China Manufacturing parts, Inc. of your responses

When you’ve finished reviewing and responding to all of the DFM reports in your quote, it’s important to notify China Manufacturing parts, Inc. that your responses are ready to be reviewed and to provide you with instructions for next steps. Click ‘Notify China Manufacturing parts’ in the blue banner above your DFM reports to send a notification to China Manufacturing parts. At this time, you will still be able to review the DFM reports but the reports will be locked from changes until a China Manufacturing parts, Inc. engineer releases the quote back to you.

Please note, if you need to make any changes while China Manufacturing parts, Inc. is reviewing your responses, you can click ‘Edit quote’. After you’ve made your corrections, please remember to click ‘Notify China Manufacturing parts’ again so that the China Manufacturing parts, Inc. engineer can resume reviewing your responses.

How to Review Injection Molding DFM Feedback Video Tutorial

Frequently asked questions about DFM reports

Where can I find all DFM reports of all part revisions?

Before the deposit is made, you can find the DFM reports associated with all part revisions in Revision history. After the deposit is made, the DFM reports for the current part revision will be accessible in the Order details.

When is the DFM analysis process complete?

When all of the required items are satisfied, and the analyses in the PEG report (Final DFM) are approved by you and sent back to China Manufacturing parts.

Is there a cost associated with DFM analysis?

No, we offer this guided expertise free of charge.

What information can I find in the DFM reports?

Depending on how optimized your design is for the Injection Molding process, we may provide Injection Molding DFM feedback to call out risks or design changes you need to consider or make prior to placing an order.

The first few rounds of DFM reports will focus on preliminary analysis, including draft analysis, parting lines, thickness analysis, and tolerance feasibility.

If you decide to proceed with the order, China Manufacturing parts, Inc. will provide more in-depth DFM feedback including warp analysis, gate location, weld line, ejector pin location, and side actions.

If your design is not sufficiently optimized for Injection Molding, we may decline the opportunity and provide high-level guidance on how to best design for Injection Molding.