Time to read: 7 min

Historically, gear fabrication methods fall into three main categories: generation, forming, and form cutting. As new technologies are developed, there may be new gear machining methods added to the list, but the big three are still the most common ways to make a gear:

- Gear generation methods use cutting tools in the shape of the desired gear profile to create the gear (rack cutters, gear shaping, and gear hobbing).

- Gear forming processes create gears without using cutting tools (rolling, casting, powder metallurgy, 3D printing).

- Gear form cutting involves tools that are used to create the gear profile (gear milling, shaping, slotting, planing, and EDM).

Gear Generation

Sunderland Method

Rack type cutters are used in one of the primary methods of gear generation. The process is also known as the Sunderland method, which consists of a rack cutter that has rake and clearance angles to create the teeth profile on a gear blank. It uses specific relative motion between the workpiece and the cutter during machining to produce teeth profiles and is similar to a rack and pinion as depicted in Figure 2.

The teeth profiles follow a geometry that consists of an involute of a circle — basically a spiraling curve traced by the end of an imaginary string unwinding itself from that stationary circle — or if you trace the point of contact from one tooth to another as shown on Figure 1.

The Sunderland method is excellent at creating teeth of uniform shape, and all gears that are cut by the same cutter will, in theory, gear correctly with one another. So, gear designs that require high precision — even double helix gears — can be fabricated with this method. And because the Sunderland principle has been maintained since its invention, manuals and documentation are widely available and relevant even for new machine designs.

Gear shaping

In this method of gear generation, a cutter and gear blank are connected by gears so that they don’t roll together as the cutter reciprocates. The cutter starts carving its way to the desired depth, as seen in Figure 3, then the cutter and gear blank rotates slowly as the gear teeth are cut in the gear blanks.

Gear shaping is commonly used for cutting spur gears, herringbone gears, and ratchet gears. This method can be used for other types of gears, but since you are using a cutter that reciprocates the gear shape, it has been useful for the gear types mentioned above making the setup easy during production. You can still manufacture these types of gears with other methods, but consider the advantages of gear shaping regarding speed, design and setup during mass production. However, this method is not the best option for internal gears and worm gears, due to the position of the cutter (on the outside) and cut direction.

Gear Hobbing

Gear hobbing produces gear teeth by rotating a cylindrically shaped cutter called a “hob” depicted in Figure 4. The hob can be single threaded, depending how many teeth per revolution should be generated.

Spur gears are most often fabricated with this method, although a variety of other gears like cycloid gears, helical gears, worm gears, ratchets and sprockets are all made by hobbing. It’s critical that the hob is well designed, especially when cutting a complex geometry. This process typically does not work for internal gears. Similar to gear shaping, the method has advantages in the setup but only for exterior cuts, since the hob is cutting the outside of the gear blanks.

Gear Form Cutting

The next primary gear making method is form cutting. This process isn’t preferred because of its limitations — low productivity and poor product quality. However, the various form cutting techniques are useful alternatives for repair and maintenance when necessary.

Shaping, Planing and Slotting

When shaping, the workpiece is fixed and the tool on the ram is moved back and forth across the workpiece (see Figure 5). When planing, the tool is fixed and the workpiece travels on the table back and forth under the tool (see Figure 6). When slotting, the workpiece is held stationary and the tool on the ram is moved up and down across the workpiece (See Figure 7).

![gear planing method]()

Figure 5: Gear form cutting – planing ![gear form cutting: shaping]()

Figure 6: Gear form cutting – shaping

Both shaper and planer cut in straight lines. However, the shaper handles small size geometries, while the planer is built for larger applications. Shapers can be used to create slots, grooves and keyways. Slotting is essentially a vertical shaper that cuts internal gears and grooves.

Milling

The milling form cutting method is relatively limited in its use, but is well suited to create complex gear geometries. Milling is used to make helical and spur gear wheels for a range of different industries, including automobile transmissions, and to create hob cutters .

This method is slow, and creates extensive heat transfer to the workpiece, so successive teeth should not be milled one right after the other.

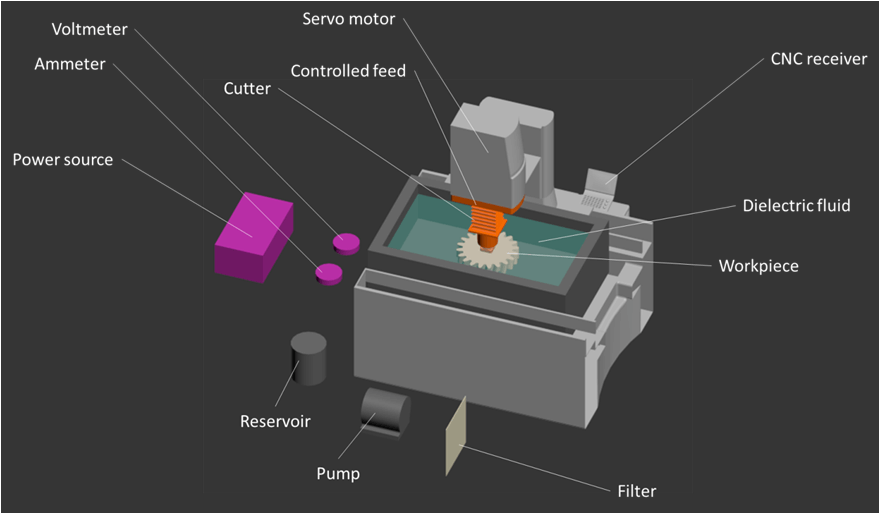

Electrical discharge Machining (EDM)

EDM is a manufacturing process where material is removed from the workpiece by applying a series of current discharges between two electrodes separated by a dielectric bath liquid.

EDM is good at cutting complex geometries of all sizes, but it has its limitations. If you don’t have a good control and program, it’s easy to damage part surfaces, especially curved teeth profiles that are so challenging for CNC programs to execute. But high quality and intuitive 3D modeling and CAM software, like Feature CAM, Autodesk Fusion, Master CAM and others, can produce the smooth motion needed to cut curved teeth.

EDM machines have improved in recent years. Early EDM machines and uses of this process had limitations, but they have been evolving. This evolution has minimized issues with surface finishes, improved cutting precision and resulting material properties (microstructure, mechanical properties, etc). The process can achieve tolerances as tight as thousandths of an inch and create both small (diameter of fractions of an inch) and large gears (diameter of over 20 inches). This process is used for both delicate applications in watches and clocks and to cut more robust gears like those used in race cars.

Gear Forming

Rolling

Rolling is one of the oldest forming processes. It forms the gear through hot or cold rolling a blank workpiece through two or three dies as depicted in Figure 10.

When material saving is a critical concern during manufacturing, rolling is a good option since there’s no chip generation. However, to get an efficient process, you must consider rolling parameters, deformations and microstructure effects before ramping up production.

Casting

Casting is a forming process used to create gear blanks (that are then machined) and full gears with cast teeth profiles. Tolerances and accuracy are crucial considerations when casting gears, and creating casting molds entails a lot of up-front costs. However, once the mold and process parameters are determined, large production quantities justify the investment.

Sand casting is used primarily to produce gear blanks to be used on other processes. Fully functioning spur, helical worm, cluster, and bevel gears are all made by gear casting, and are used in washing machines, small appliances, hand tools, toys, and cameras.

Powder metallurgy

Powder metallurgy is a high-precision forming method that’s a cost effective alternative to conventional, machine-finished steel and cast iron gears. However, this method is not suited for larger gear sizes, but is adept at creating small, high-quality spur, bevel and spiral gears. Because of the porosity of the formed material, larger gears have less fatigue and impact resistance, though a sintering process can be used to improve its mechanical properties.

Powder metallurgy is also particularly useful when gear designs include holes, depressions and different surface levels or projections. You’ll find these gears in appliances, farm, lawn, and garden equipment, automobiles, trucks, and military vehicles.

Additive Manufacturing

Also known as 3D printing, additive manufacturing constructs a three-dimensional object, layer by layer, from a CAD 3D model. Due to the nature of the process, additive machines can form complex designs with lattice structures. These structures can be modeled to achieve mass reduction not easily obtained through conventional methods. This type of geometry is often created using 3D topology optimization and generative computer design.

Conventional and non-circular gears can be fabricated with additive manufacturing processes, and high quality 3D printers are relatively affordable and widely available. Because of this availability, it’s become the choice for repairs and mechanical projects like educational toys or other gadgets needing fully functional gears. You can also include other features and even combine geometry with the gear shapes to add customized shafts, keys, or grooves to the same solid.

Conclusion

As you can see, there are many ways to make a gear, whether you’re generating, forming or cutting one. We hope this article helped you to understand the most common fabrication methods. If you found this article interesting, share it on Linkedin! You can learn more about China Manufacturing parts’s gear fabrication capabilities here.

To experience the China Manufacturing parts, Inc. platform for yourself, sign up for a free account.