3D Printing Materials

ABS

PETG

PLA

ABS

3D Printing Services

FDM machines can be categorized into two main categories: professional and hobbyist grade. At China Manufacturing parts, all parts produced in PLA are made on hobbyist grade machines to keep costs low and leverage breakaway support. All other FDM materials, specifically ABS, are produced on professional grade machines with soluble support material for greater accuracy and strength.

| Prusa i3 MK2 | Ultimaker 2 | Type A Machines Series 1 Pro | |

|---|---|---|---|

| Build Bed Size [x,y,z] | 250 x 210 x 200 mm

9.84 x 8.3 x 8 in | 342 x 357 x 388 mm 13.4 x 14.05 x 15.28 in | 305 x 305 x 305 mm

12 x 12 x 12 in |

| Materials | PLA | PLA | PLA |

| Value | $699 | $2,450 | $3,995 |

| UPrintSE Plus | Fortus 400/450mc | |

|---|---|---|

| Build Bed Size [x, y, z] | 203 x 203 x 152 mm 8 x 8 x 6 in | 355 x 254 x 254 mm

14 x 10 x 10 in |

| Materials | ABS | ABS |

| Value | $699 | $2,450 |

ABS

PETG

PLA

ABS

Max Part Size

Min Feature Size

Tolerance

Min Wall Thickness

Min Hole Diameter

Min Gaps for Mating Parts

Additional Design for Manufacturing Tips

Cost Saving Tips

Fused deposition modeling (FDM) is a 3D printing technology (also known as additive manufacturing) commonly used for modeling, prototyping, and production applications. Each layer is created by extruding material from a nozzle to produce 3D objects.

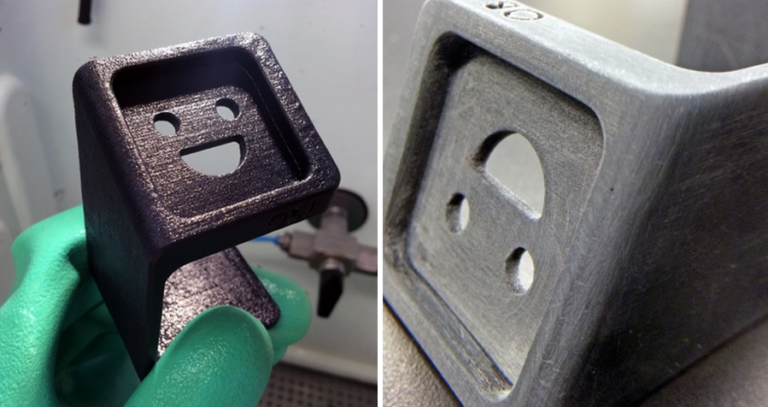

FDM processes require support material, either breakaway or soluble, so it’s important to keep this in mind when choosing this process as it can affect the final part.

Learn More

Learn More