YOU MIGHT ALSO BE INTERESTED IN

Recommended Wall Thickness for 3D Printing

Learn More

Methods for Cleaning 3D Printed Parts

Learn More

3D Printing Materials

Processes

Production Time

Colors

Resolution

Infill

Price

Applications

Nylon 12 is a synthetic 3D printed polymer material that’s strong, durable and also has some flex to it. As a result, Nylon is a great material choice for snap fits, brackets, clips, and spring features. Nylon is also used for its thermal applications and can withstand temperatures up to 177℃.

Nylon 12 parts are susceptible to shrinkage, due to the laser sintering mechanism and the cooling process. For large, thin parts, warping is highly likely, so we strongly recommend increasing thickness or adding ribbing in the design to mitigate risk.

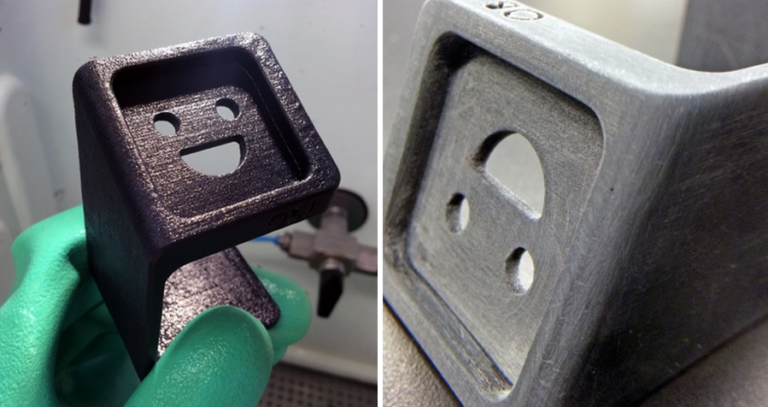

China Manufacturing parts offers Nylon 12 produced through Selective Laser Sintering (SLS) and also Multi Jet Fusion (MJF). As a result, a finished product from either of these technologies will have slightly different properties and risks. MJF machines deposit a detailing agent along the exterior of a part that, after media blasting, results in a less coarse surface finish compared with the SLS process. MJF parts also come off the bed grey, whereas SLS Nylon parts are white. Both can be dyed black afterwards.

MJF has a slightly better resolution compared with SLS, with a layer height at 0.08 mm compared with 0.1 mm for SLS. If you’re prototyping smaller quantities under around 25 units, SLS is generally more cost-effective. At higher bridge production quantities, MJF becomes more cost effective because of the machine’s modular design and faster production speed.

As for mechanical properties, MJF Nylon has a higher flexural strength than SLS Nylon. Therefore, MJF Nylon is typically considered more often for end-use parts and functional testing under higher loads.

Process

Tensile Strength

Elongation at Break

Modulus of Elasticity

Flexural Strength

The texture of SLS Nylon is similar to a very fine grit sandpaper with a matte finish. MJF Nylon parts are generally slightly smoother. Un-dyed MJF Nylon is grey, which may vary in shades across the same part of a surface. When dyed black, both SLS and MJF Nylon have a matte appearance.

Process

Min Wall Thickness

Min Clearance + Gaps for Fit

Max Part Size [x, y, z]

Internal Cavities

Be sure to have a clearance to remove the support powder!

Threads & Inserts

Minimum 0.1 mm clearance is required for printed threads.

Text Guidelines

Raised features: 0.6 mm minimum

Recessed features: 0.5 mm minimum

Learn More

Learn More