3D Printing Materials

Accura 25

Accura ClearVue

Accura 25

3D Printing Services

Lifecycle

Lead Time

Resolution

Materials

Our global manufacturing ecosystem includes manufacturing partners with 3D Systems professional grade ProJet printers that are capable of very precise and highly detailed printing. The main sections of the machine include the build chamber and the material chamber below. The build bed can be removed to carefully detach the printed part and clean it of any remaining support material.

| ProJet 6000 HD | ProJet 7000 | |

|---|---|---|

| Build Bed Size [x, y, z] | 254 x 254 x 254 mm | 381 x 381 x 254 mm |

| Materials | Accura 25, Accura ClearVue | Accura 25, Accura ClearVue |

| Value | $185,000 | $250,000 |

Accura 25

Accura ClearVue

Accura 25

Max Part Size [x, y, z]

Gaps for Mating Parts

Tolerance

Min Wall Thickness

Min Hole Diameter

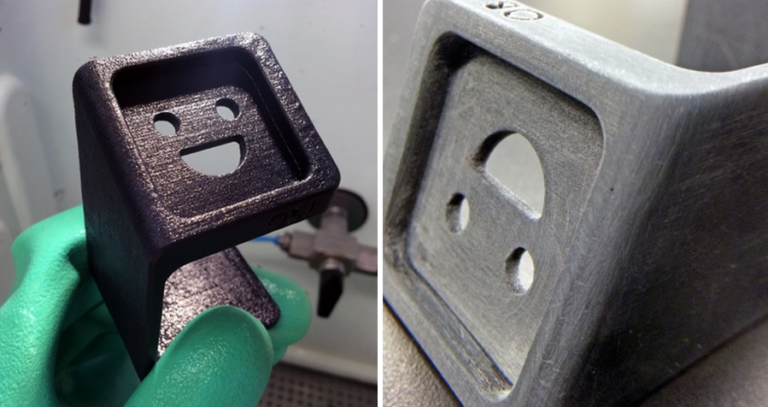

Note that any surface in contact with support will have small nubs in the final product as a result of support removal. To optimize the overall surface smoothness of the part, avoid extra overhangs, steep slopes, or large flat planes that may add more structural support.

Cost Saving Tip

Parts can be designed hollow to reduce material usage. Make sure to design a drainage hole that’s at least 4mm in diameter to allow removal of trapped resin. Surrounding walls should be at least 2mm thick to ensure a successful print.

Stereolithography, or SLA, is a 3D printing technology known for achieving highly detailed and functionally accurate parts. The technology utilizes a mirror that is programmed to direct an ultraviolet laser to draw and cure a part’s cross-section onto a vat of photopolymer resin. After each layer, the build platform lowers and a recouter blade wipes over a new layer of material on the top of the tank.

Once the part is complete, it is removed from the build chamber, cleaned of support and excess resin (typically using isopropyl alcohol), and then placed in a UV oven for further curing. This ensures the part reaches its optimal physical properties.

Learn More

Learn More