Time to read: 4 min

3D printing has grown from $4.4 billion in 2013 to an industry bringing in a projected $21 billion in 2021. This major growth is due to the growing number of applications of this technology across industries from printing food to building colonies on Mars. Other more practical applications for 3D printing include innovations in the healthcare, automotive, construction, and manufacturing sectors. Plastics, metals, ceramics, and even human cells are being used as material to print vital components of these industries — faster and at a lower cost. By starting with a 3D digital file (either downloading it from the internet or designing it with software), complex shapes can be uploaded to a computer and printed layer by layer into a tangible, usable object. 3D printing requires a 3D printer, the proper materials, and a 3D sketch. Individuals might even choose to contract 3D printing services if they do not have all the necessary parts for the job, or need help tooling a custom prototype or part as one stage of a bigger project. The future of 3D printing is still being realized, with professionals in several industries already making some groundbreaking strides — for this reason, some are calling the 3D printer the harbinger of the 4th industrial revolution.

Healthcare

Using human tissue and cells as material, healthcare professionals are now able to 3D print skin, body parts, and organs with cells that are compatible with a particular person’s anatomy — leaving less room for rejection. 3D printing is powering medical breakthroughs comprising the bioprinting, replication, and prosthetics fields. There are several medical advancements in which 3D printing is lending a hand. The technology has encouraged the anticipation of solving organ donation shortages, transforming heart surgery, and the creation of custom braces for chronic health problems such as scoliosis. Additionally, sterile surgical instruments can be made quickly while remaining inexpensive, and correcting deformity due to certain trauma and injury can be made possible and easier with 3D printing. In addition to being able to 3D print surgical instruments, the technology can also help improve the healthcare supply chain by making medical items more available, abundant, and obtainable at a lower cost.

Education

Science, technology, engineering, and math (STEM) have become increasingly popular, thanks in part to the fact that 3D printing is helping transform classrooms at every level, from K-12 to college. For instance, engineering students can now print out their prototypes, students studying architecture can make 3D models of their structures, and chemistry students can print 3D sculptures of molecules. Teachers of various subjects who have access to a 3D printer and materials can print out educational aids. 3D printing can supplement a curriculum, help increase problem-solving skills, and foster a deeper, more foundational knowledge of complex subjects.

Aerospace

Boeing, Airbus, and even NASA are all taking advantage of 3D printing. The ability to quickly produce lightweight parts at a low cost is valuable to aerospace professionals. 3D printing parts for engines, satellite production, aircraft body parts and fixtures, and even taxi drones to facilitate takeoffs and landings are changing the aerospace manufacturing and production chains. These lightweight parts are affordable, but also help cut fuel costs.

Automotive

The successful car company Audi has been using 3D printing for quite some time now and has no plans of stopping. Similar to aerospace, the automotive industry is heavily interested in the ability to print lightweight parts — some of which may be complex and seldom-used — on-demand and at low cost. The automotive industry can use 3D printing for engine and body parts, chassis, and in the future may be able to 3D print whole cars much faster than current manufacturing times currently allow for — making them more fuel-efficient and reducing factory waste byproduct in the process.

Construction

Construction is using 3D printing to fabricate anything from tiny hardware to lightweight, durable tools to printing entire houses. 3D printing is making its way into the interior design industry to produce office chairs, desks, and tables. A private firm in China has claimed to have 3D printed 10 full-sized, detached single-story houses in 24 hours. It is not out of the realm of possibility to think that full cities can be 3D printed at record speed. 3D printing can be attractive to professionals in the construction industry because it cuts down labor time and cost, and minimizes inefficiencies. This is especially relevant since these professionals are looking to build complex, intricate structures in a shorter, more sustainable manner.

Manufacturing

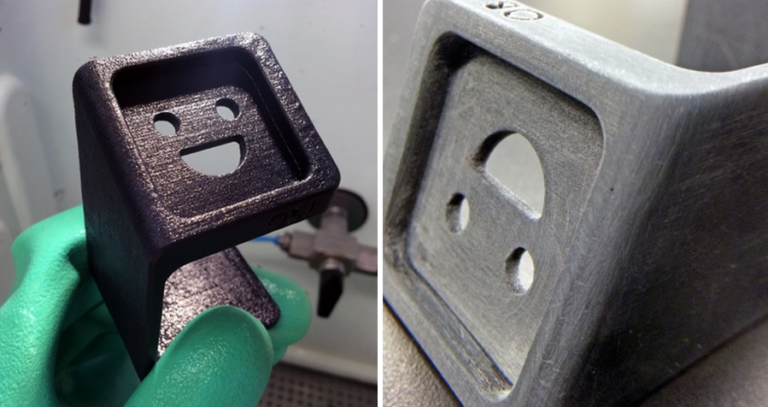

Most of the industries above have taken advantage of 3D printing for manufacturing benefits. Traditional manufacturing processes that have been in place for generations are now being transformed — allowing goods to be produced at an extraordinary speed, using less and fewer materials, and reducing labor. 3D printing can be used alongside, or in place of, CNC machining to produce precise iterations of complex, custom manufactured parts, custom manufacturing parts. 3D printing and CNC machining will be used throughout manufacturing chains, cutting the cost for manufacturing mid to large units of products, or one-off prototypes. 3D printing during the manufacturing process can also cut down on waste, making for a more sustainable manufacturing process for any industry and reducing the carbon footprint for one of the most wasteful aspects of any industry.

Robotics

Robotics, and especially industrial robots, are extremely complicated machines with delicate parts. 3D printing can be used to replace these parts in a quick, cost-effective way. Robotics, when used for 3D printers, can move in an incredible variety of angles, able to create complex shapes for custom and large-scale objects. It is not far off to think that sending robotics with 3D printers to Mars could lead to the building of other larger robotics to 3D print houses for a colony in space. The applications for 3D printing are fascinating and only recently becoming realized. It is not known fully how this will impact industries going forward in the future — however, the possibilities are seemingly limitless.