Time to read: 5 min

We’re seeking out the most amazing hardware companies and engineers to help uncover the many challenges, lessons, and philosophies behind what makes them so awesome and how they develop their products. In this week’s Hardware Spotlight, we had the chance to sit down with Taylor Umphreys co-founder and CEO at Zuli. Taylor and his co-founders, Sid Bhargava and Ben Chang, founded Zuli with the goal of simplifying the smart home experience. We chatted with Taylor about vision, development cycles, and advice for launching a Kickstarter campaign.

What inspired you to create the Zuli Smartplug?

Sid, Ben and myself all went to UC Santa Barbara where we studied electrical engineering. In our final two years of college, we became really interested in home automation. We thought your home should simply be smarter; that it should do more for you.

What makes the Zuli Smartplug different than other home automation products on the market?

When we first started playing around with the products that were out there, three main problem areas became apparent: cost, complexity, and user experience. We wanted Zuli to uniquely take the user experience to a new level. Our set up process is literally as simple as plugging in your Smartplug, plugging in your appliance and then downloading the app. Additionally, the Bluetooth mesh network that’s created when you plug in three or more Smartplugs, tracks your location inside the home as you move and introduces a new level of intelligence, contextual awareness and understanding of our preferences and how we live our lives.

“External resources in specific areas can greatly accelerate your timeline.”

How did you tackle the design and mechanical engineering aspects of the project as a group of electrical engineers?

We quickly realized that industrial design was not our forté. So pretty early on we sought out an industrial design partner and found one in Astro Studios, the designers of the Nike FuelBand and Xbox360. Immediately they were synced up with our vision for the product.

Would you recommend outsourcing for other young startups?

Whenever possible, I would suggest working internally because things just tend to go a bit smoother, but if you’re a small team, like us, then external resources in specific areas can greatly accelerate your timeline with the goal of developing a quality product. Outsourcing can go quicker than investing the time and energy in seeking an internal hire and also can be a great fit for short-term projects, where a full-time hire is not always necessary.

The biggest perks about China Manufacturing parts, Inc. were price, speed, and ease of use.

Now for the nitty gritty! Tell us about your very first prototype.

Our first prototype was a breadboard and I can tell you first hand that it was a giant rat’s nest of wires. We actually ended up using it to enter UC Santa Barbara’s New Venture Competition. However, the night before the competition we decided to fix the rat’s nest and make it look a bit nicer- which ended with us blowing up the whole board at 3am. After that, we started working towards our first PCB, printed circuit board.

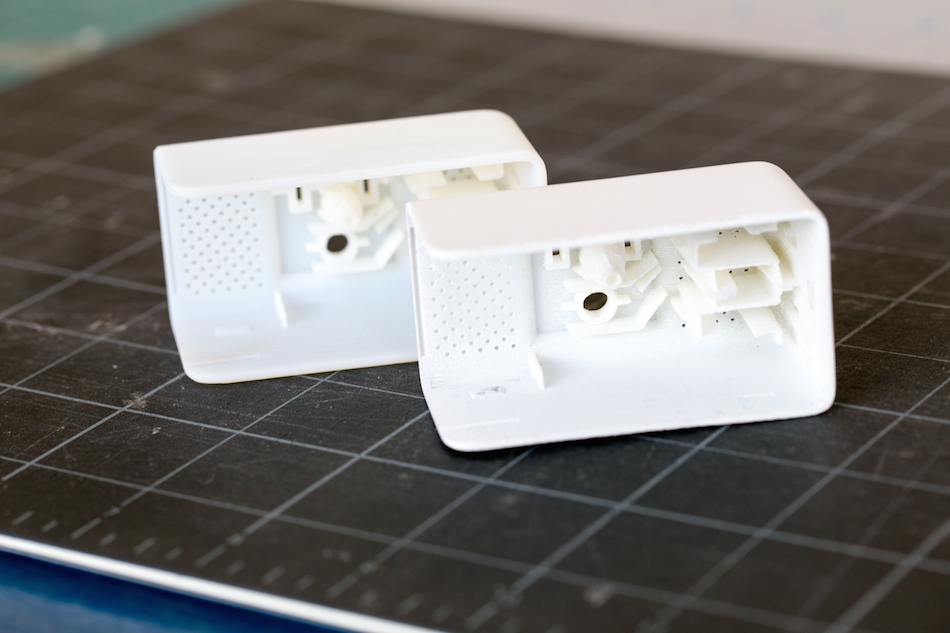

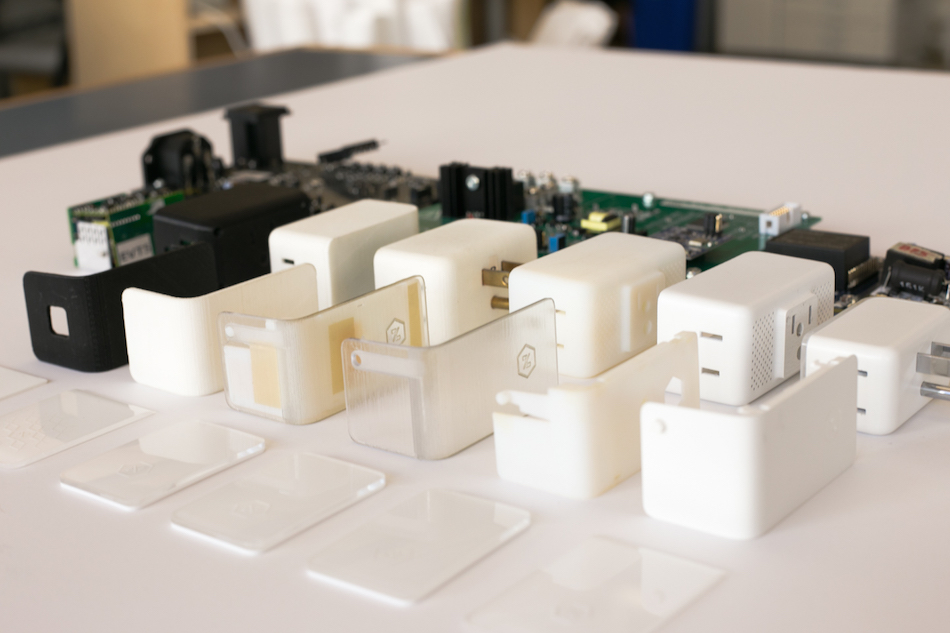

How did you use 3D printing to aid your product development cycles?

When we started working on DFM, design for manufacturing, we had a big need for rapid prototyping to test designs and fit of the plastics before starting tooling. Before being introduced to Fictiv, we were trying to access 3D prints through mediums that didn’t work well for us. The first was finding someone we knew or a local design firm that had a printer we could use and then waiting sometimes 3 or 4 days until the machine was free. A colossal waste of time. The second method was utilizing another 3D printing service in So-Cal where we had to do a lot of back and forth with their engineers to make sure they understood which plastics to use and what needed to be done with our project. None of these produced a solution we were satisfied with.

What was different about China Manufacturing parts?

The biggest perks about China Manufacturing parts, Inc. were price, speed, and ease of use in terms of loading up the files and having prints shipped without a lot of in-depth work on our side. This made it really easy to make a tweak, load it up to China Manufacturing parts, Inc. and then receive a part in a day or two to look at. It was a huge help.

“Build and test things as quickly as possible.”

So once you had a working prototype how did you approach user testing?

Our launch on Kickstarter was the first time sharing our vision of the product with the public and we received a lot of feedback from people through that medium. We received a ton of suggestions for potential features as well as mentions of features people really appreciated. Since that time we’ve been leaning heavily on our backer community to acquire additional feedback through usability testing. We have another usability test coming up soon where we’ll film people setting up the product in order to learn where people stumble in the process.

Any wise advice on building a successful Kickstarter campaign?

Be very prepared for it. When we started we were not fully prepared for what a campaign was going to require. We did all of the video and page design ourselves which took more time than we expected and we were working on finalizing the Kickstarter page up until the last minute. What we forgot to prepare for while we focused on page perfection was the finding and building of media and social sharing outlets through which to actually share our page. Once the project goes live, don’t underestimate the time that will be spent answering questions, writing updates, doing outreach and everything else that comes with making a project successful. The more you can prepare upfront (update calendar, standard responses to questions, ect.) the easier it will be.

What has been the greatest lesson learned from this project so far?

Build and test things as quickly as possible. In the beginning we spent a lot of time trying to tweak and perfect things before we made any physical changes to the models. All this did was slow us down in the end because it’s much easier and more effective to build a 3D prototype and then see and feel which changes need to be made rather than stare at 3D drawings for a day or two, trying to find every little change or tweak. Prototype, test and reiterate quickly.