Time to read: 5 min

Recently I sat down with MacroFab CEO Misha Govshteyn to talk about building supply chain resilience, during a webinar hosted by industry journalist Philip Stoten. We looked at supply chains in the COVID-19 era and explored how we got here, then discussed the digitally connected supply chain of the future.

How we got here: a perfect storm of disruption

There were numerous supply chain disruptions before the COVID-19 pandemic, and there will be many more in the future. 2018-2019 saw disruptions due to tariff disagreements between the U.S. and China, and 2020 began with expected disruptions in January during Chinese New Year.

At the end of January, news of the novel coronavirus, COVID-19, emerged from Wuhan, China, and Chinese factories remained shuttered after Chinese New Year. Demand disruption hit the European supply chain in late February and the U.S. supply chain in early March, and countries’ economies began to slow in March and April, as the disease spread around the world. In March, the U.S. invoked the Defense Production Act.

China began its return to normal manufacturing in April, and now we’re all wondering what economic recovery and life after COVID-19 will look like.

After the storm

Like many massive storms, this one will leave a trail of destruction, like high unemployment, and a world that will never be the same. So, what happens next?

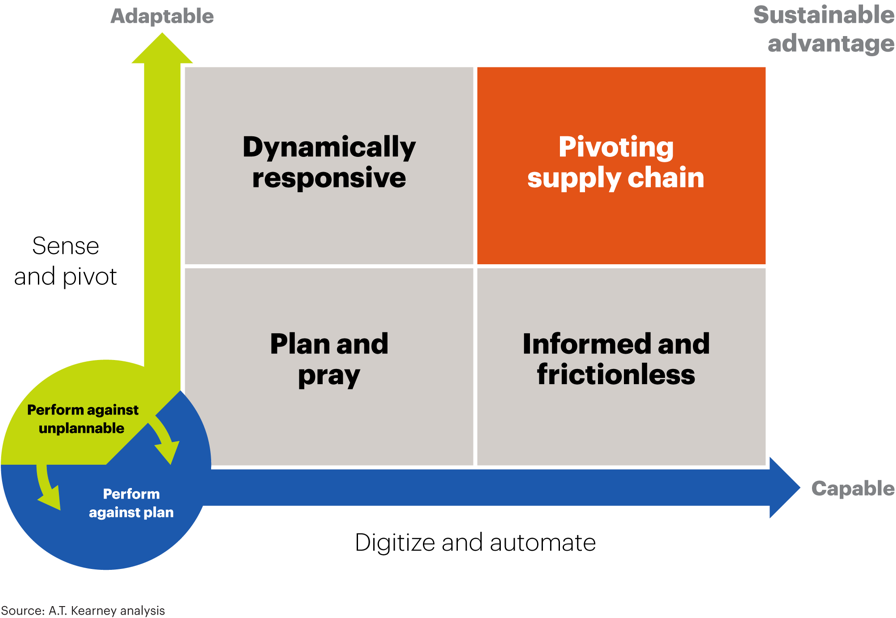

We envision supply chains that are more agile and resilient, more adaptable, with more choices. We believe businesses can reach that ideal by implementing digital supply chains.

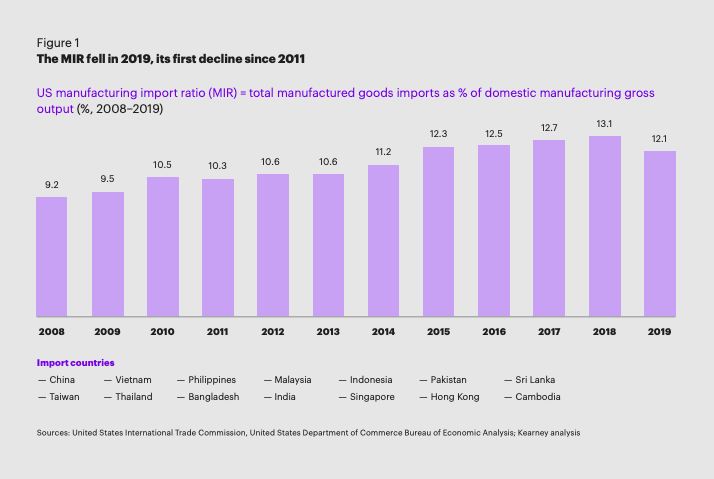

Supply chains started rebalancing before 2020. The U.S. manufacturing import ratio (MIR), the total number of imports of manufactured goods as a percentage of domestic manufacturing gross output, fell in 2019, for the first time since 2011.

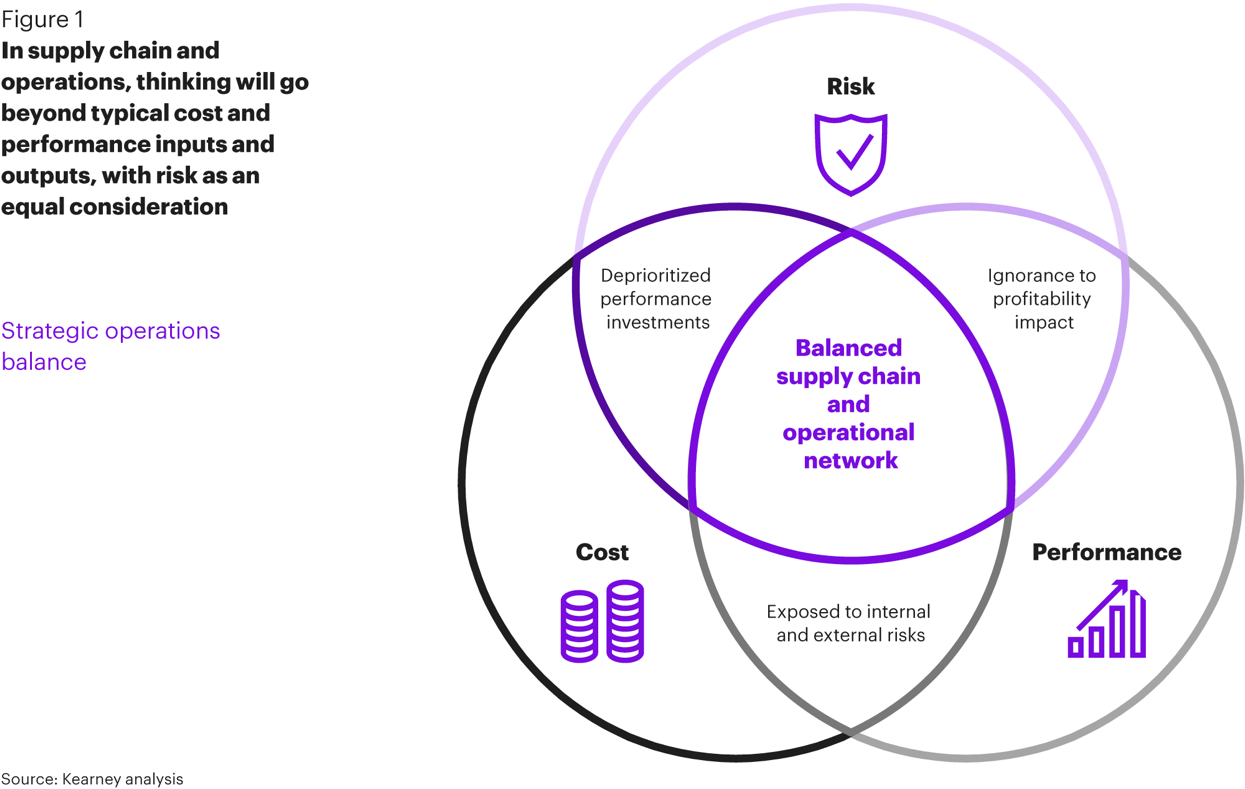

At China Manufacturing parts, we see a need to balance priorities to strike a strategic operations balance. Cost is no longer the overriding objective. Instead, in supply chain and operations, thinking will need to go beyond typical cost and performance inputs and outputs and factor in risk as an equivalent consideration.

The supply chain of the future is digital

Digital supply chains are agile, resilient, accessible, and sustainable.

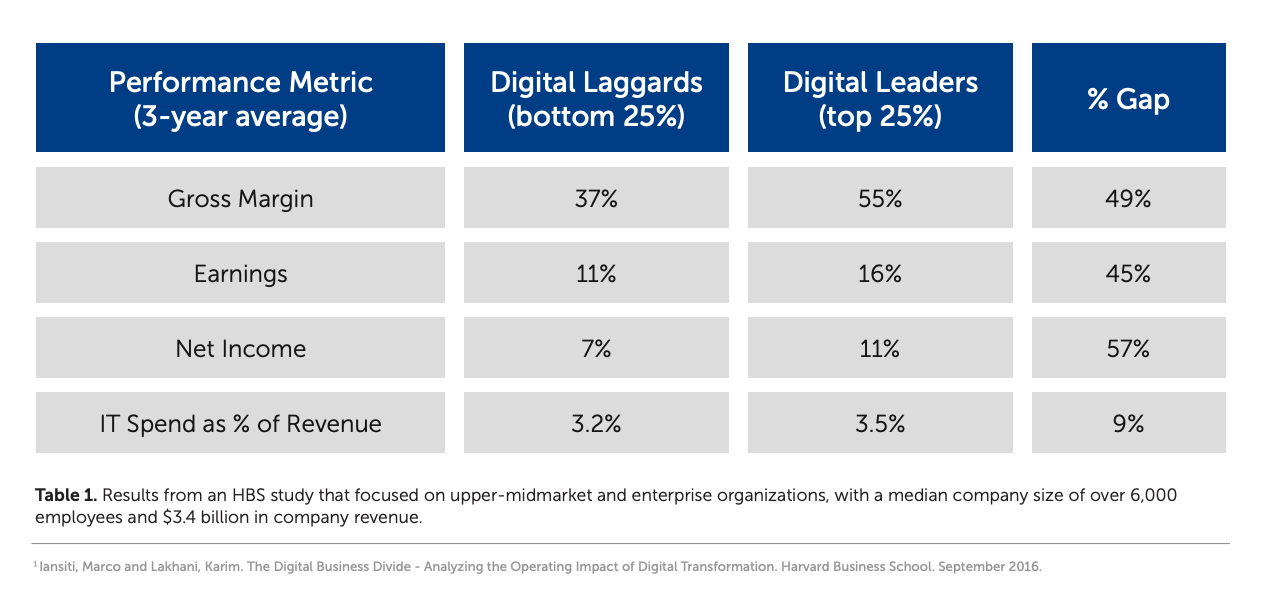

They’re also profitable: A Harvard Business School study found that companies who digitized their operations performed better than those who didn’t.

Digital manufacturing benefits enterprise companies because results are better and more consistent, production is less risky, and it’s easier to match to the right factory every time. Engineering teams can use self-service tools, real-time access to information, and a digital thread of information from design to the production stage. Purchasing teams benefit from a fast, digital-first user experience, better communication, and a true market-driven price.

Digital platforms enable choice and flexibility, with instant access to a wide range of processes, materials, geographies, lead times, and prices. They offer reduced overhead costs, virtually unlimited capacity, instant access to vetted suppliers, on-demand supply, and low minimum order quantities (MOQs).

Digital platforms reduce reliance on a single supplier or region. The key ingredients are highly vetted global manufacturing partners, people with deep manufacturing expertise, and an intelligent cloud platform. Digital platforms produce quality parts at unmatched speeds, allowing simple, secure file uploads; instant quotes and DFM; intelligent partner matching; and quality assurance.

Elasticity on the capacity side of things, capacity on demand, means you can ramp up by 20 times and shift quickly. As Misha said during our conversation, it also means tapping into the right resources.

“China Manufacturing parts has several hundred factories they can tap into,” said Misha. “We have 50 factories in our network, and our capacity is immense, what is just the right factory or machine shop for a particular job. Supply and demand is matched better by platforms like China Manufacturing parts.”

“To get the job done right, how do we get you to the best factory out there, maybe one nobody knows about?” he added. “We have factories in Mexico designed to scale, and companies can only access them through a platform like ours.”

Misha also talked about the financial benefits of working with digital platforms.

“When you work with digital platforms, it allows you to be nimble, and there’s a financial benefit,” said Misha. “What really matters is, are you able to continue to deliver product? Are you in business when your competitors aren’t?”

“Digitization lets you get there,” he said. “Companies moving to digital models are more profitable. Think about how to outrun your competition and be more profitable.”

Question: How do you build a case for digital platforms to management?

When you need to build a case for management to be more digital, the best argument is a profit- or economic-based one. Digital companies are higher on gross margins, earnings, and income, at a fraction of the IT spend.

The concept of a digital platform is to increase choice for any product development company and increase flexibility for where you produce. Vetting of suppliers is really critical here, to control quality. Digital platforms should allow lower MOQs and also allow you to have product when you need it.

Misha emphasized that our job, whatever the future brings, is to provide ultimate functionality.

“Can you move to a different region or between factories as the world is reconfiguring itself?” Misha asked. “If the answer is no, it’s time to change.”

Question: How do companies deal with quality issues when switching to digital platforms?

Philip asked me how quality issues are dealt with when companies shift to digital platforms.

With a digital platform, as you upload files, you get DFM feedback. We do more quality checks in an hour because of the digital thread we create from end to end.

From a security standpoint, we know who’s viewed a file, checked a file, and downloaded it, from upload to the part being delivered to your site. We believe a digital thread drives quality better than traditional suppliers, with better checks and balances.

Question: What is the role of government in changing the supply chain?

Philip asked about the role of government in changing the supply chain, and Misha had a really clear reply.

“We’ve never had a true free trade system,” Misha responded. “Government has always played a role. Now, we’re wondering about it because it’s impacting daily life. Government has to take an active role. You can’t let the free market take over; it’s never worked that way. That role should be rational and not come from a place of anger. Do we really want all our production done overseas? Does that even make sense? If not, let’s build it right.”

Key takeaways

Digitization drives profitability; choice and flexibility; and resilience. Digital manufacturing ecosystems bring the world of optimized manufacturing to you.

Misha advised companies to start early and make sure products are digitized and can be put into factories or machine shops through digital platforms.

“If all your parts are in your system, you can just reorder and be done,” he said. “Start digitizing now, and the benefits will be tremendous.”

My advice is to think about how digitization can help your organization create more choice about where products are made and more flexibility around how they are made. How can you be a change agent? Reach out to us at China Manufacturing parts; we’re happy to help talk through nuances for building a digital strategy inside your organization.