Time to read: 2 min

We’re happy to announce that the China Manufacturing parts, Inc. platform now includes six new CNC machining materials: four metals and two plastics. In addition to Aluminum, 3 Stainless Steel alloys, ABS, Nylon, Delrin, and Polycarbonate, you can now order 3-day CNC machined parts in:

- Acrylic

- HDPE

- 7075 Aluminum

- Brass

- 17-4 PH Stainless Steel

- 1018 Low Carbon Steel

Read on for an overview of each material. For further information on these new materials, as well as China Manufacturing parts’s CNC machining capabilities, visit the China Manufacturing parts, Inc. Capabilities Guide. To compare material properties, download our CNC material datasheet.

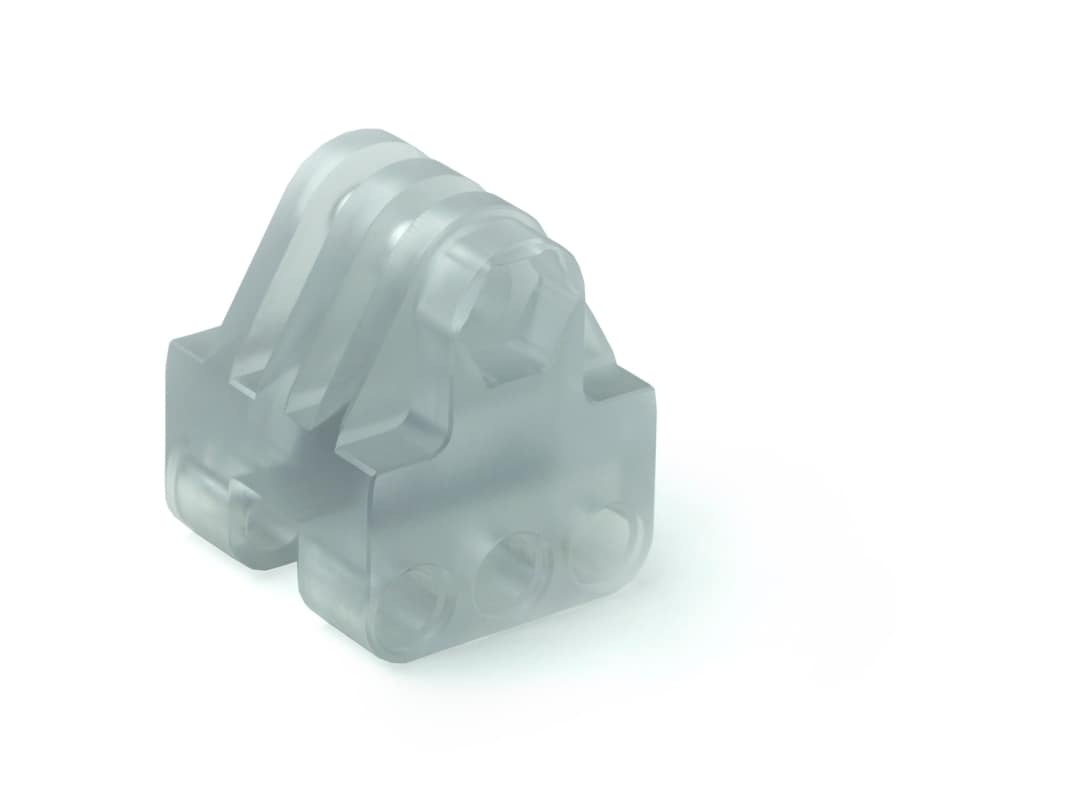

1. Acrylic

Overview: Scratch-resistant plastic material.

Common applications: Tanks, panels, and optical applications.

Colors: Optically clear, opaque

Appearance: Transparent or opaque in its unfinished state. Clear acrylic will take on a frosted, translucent appearance when machined, though can be smoothed again to an optically clear state using various finishing methods.

Design Considerations: It can be somewhat brittle in thin walled areas, so it is not recommended for delicate or complex geometries.

2. HDPE

Overview: Plastic materials that is an excellent electrical insulator and is also moisture and chemically-resistant.

Common applications: Often machined into plugs and seals

Colors: White

Appearance: HDPE is naturally opaque-white because of its crystalline structure, but can also be dyed black in more limited stock sizes. It has a waxy finish, which works well for low-friction applications.

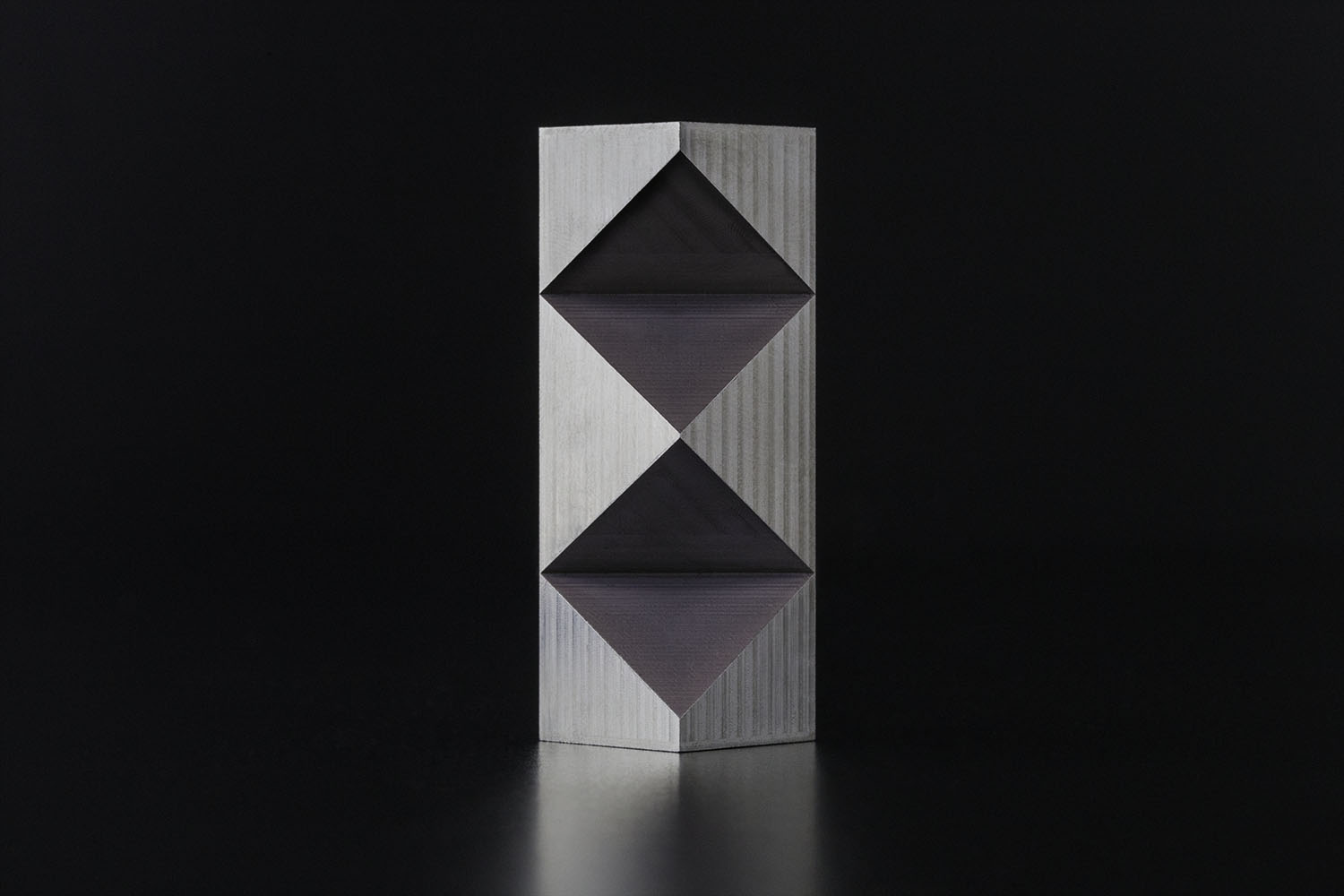

3. 7075 Aluminum

Overview: Hard, high strength alternative to 6061 Aluminum. It is also corrosion-resistant, non-magnetic and heat treatable.

Common applications: High-stress applications

Finish: Untreated aluminum generally has a dull silver/grey finish, which varies depending on the roughness of the surface. Aluminum can be anodized, media-blasted, and hand-polished to achieve a multitude of surface finishes.

4. 360 Brass

Overview: Also known as free machining brass, due to it having the highest amount of lead content of any brass alloy. This material has excellent machinability, which means minimal tool wear.

Common applications: Gears, lock components, pipe fittings, and ornamental applications

Finish: Shiny, yellow finish that varies depending on surface roughness. It can be hand-polished to increase its sheen (think trumpet or saxophone), or media blasted for more of a matte texture.

5. 17-4 PH Stainless Steel

Overview: High-strength, highly corrosion-resistant material that maintains its durability up to 1100°F. The PH in its name stands for precipitation-hardened, a type of treatment it undergoes to increase yield strength. It is magnetic and heat treatable to a hardness of approximately Rockwell C50.

Finish: The finish of stainless steel varies greatly depending on surface roughness, but it’s generally characterized as being more shiny than unfinished aluminum alloys, and slightly darker and more silver in color. Stainless steel can be powder coated, plated, polished, or media blasted to achieve a variety of finishes.

6. 1018 Low Carbon Steel

Overview: Cost effective and highly-machinable, weldable and useful where high-strength is not required.

Common applications: Fixtures and mounting plates

Finish: The finish of 1018 Steel is similar to that of Stainless Steel: generally shiny in appearance and slightly dark than aluminum alloys.Stainless steel can also be media-blasted, hand-polished, and powder coated to achieve a multitude of surface finishes.