Article contents

▸

Article

Cameron Moore

09.14.2021 Manufacturing Processes

For any engineering project, countless hours go into 3D modeling, prototyping, and refining the design. Often, the final step is to prepare your designs for the injection molding process, but where do you start?

How long will it take to go from the initial part designs to your first molded parts? This is a long and complicated process that can intimidate many an engineer.

In this article, we’ll walk you step by step through the injection molding process from start to finish and share with you the strategies we use with our customers to help save time and avoid potential pitfalls common to this complex manufacturing process.

One of the key tools our technical program managers at China Manufacturing parts, Inc. use to keep injection molding programs on track is a detailed gantt chart.

This article will go deep into each of those gantt chart steps to help you understand the process. Plus, we’re making our template available for you to download for free here, which you can use to plan out your own program.

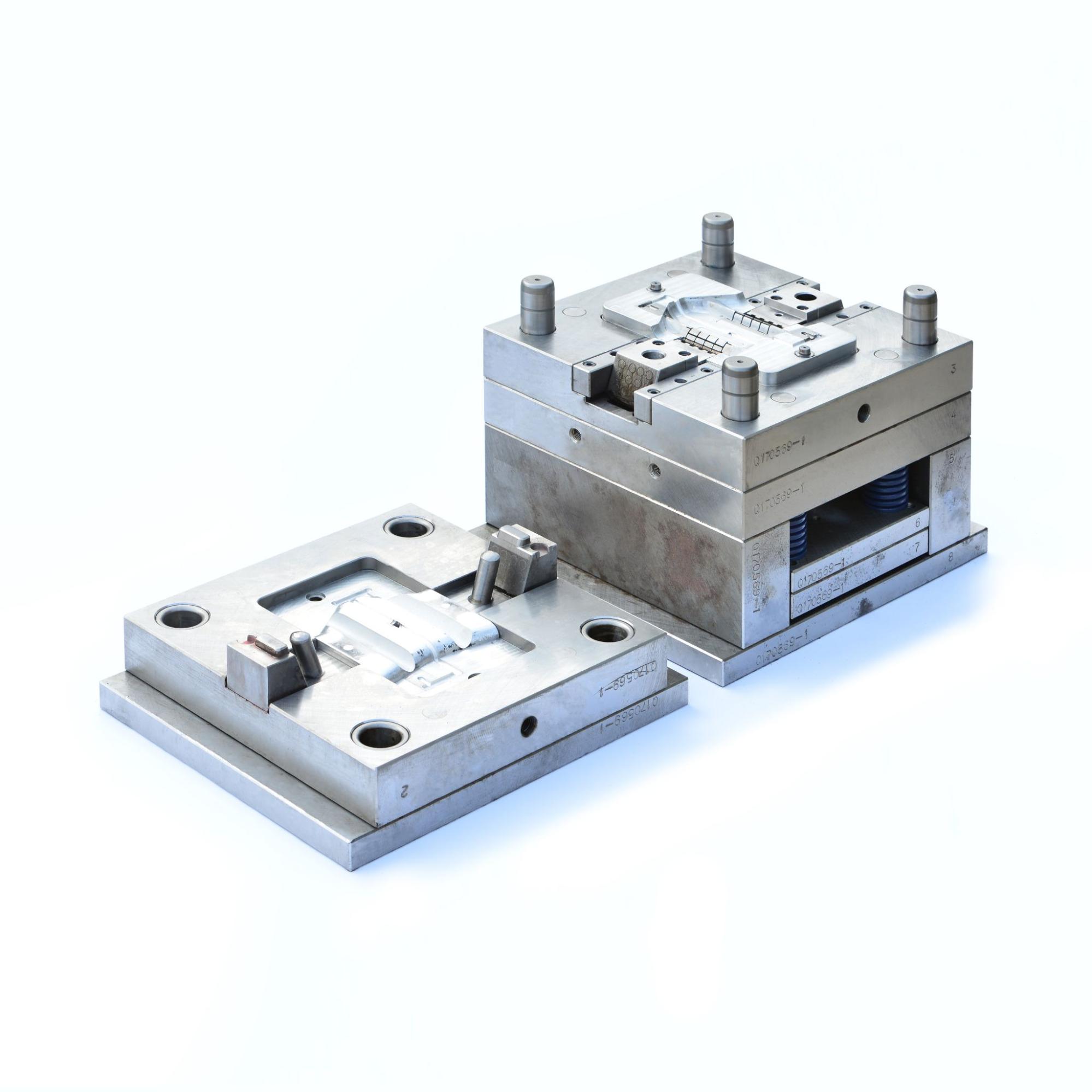

The example timeline in the gantt chart is based on the sample part shown below using a single cavity mold. The overall part size is 95.520 x 55.541 x 16.500 mm, made of a general-purpose PC/ABS plastic that’s black and has a matte SPI-B1 finish. The tooling will be made from P20 steel, with a cold runner and automatic side action.

With Fictiv, you can get T1 samples for an injection molded part like this in 12 business days, which is the timeline we’ll anchor around for the purposes of this article.

If you’re working with a traditional injection molding supplier, that timeline will typically be about twice as long (this is included in the downloadable template for your reference).

Now, let’s dive into the process!

The first step of the process is to finalize your designs for injection molding, which encompasses the part as well as the mold design.

It’s common practice in the industry for molding suppliers to hold back design for manufacturability (DFM) feedback until after an order is placed. But this is where the most time in a project can be lost.

Typically design engineers move onto new projects once an order is placed, which leaves limited resources for any injection molding design corrections should there be issues or concerns (which is common).

Additionally, the longer you wait to make design adjustments, the more likely it is that your team may have limited flexibility to make changes based on other parts in the assembly.

That’s why we recommend customers engage early on in the process to start optimizing their designs for injection molding, which can take significant time. For more tips here, check out our Injection Molding Design Guide.

The initial phase of mold design involves laying out the part and deciding how it will be oriented when it’s being molded. This layout provides useful information about mold size and the corresponding steel block required to create the tooling.

It’s especially critical to know the size of the steel block because that way your supplier can order and ship the steel before the design of the tool is finished.

Once the steel arrives, initial work starts to prepare the steel for machining. The steel blocks need to be faced off so that all edges are perpendicular to each other and have a smooth surface to begin machining. This step can take 2-3 days and is needed before the CNC machining can begin.

At China Manufacturing parts, our partners buy steel that’s ready to machine, which is more expensive but saves days of prep time.

The next phase of mold design is to flesh out details like finalizing the design of the core and cavity and building a complete BOM (bill of materials) with all of the small parts and other components needed. After creating a 3D CAD model of the mold, (which takes one to two days depending on the size and complexity of the part) the 2D drawing is completed in another day or two.

By working on different aspects of the mold in parallel, the mold creation process becomes a good deal more efficient — by 5 or 6 days — when compared to a more linear approach.

Finally, once the part design is confirmed, CNC programming begins, while the cooling lines and ejector pin holes are drilled. A CAM (computer-aided manufacturing) program is used to develop the G-code that will run the machine to make the mold parts. This milling process takes about two days and can begin once the DFM is approved and 3D CAD modeling starts.

As the mold design is finalized and the CNC programming progresses, it’s time to start preparing other materials. If you’re working with China Manufacturing parts, at this point the steel for the core and cavity inserts for the mold base has already been ordered and typically arrives in a couple of days.

In this step, it’s a good idea to spend a little extra to get core and cavity inserts that are already the exact sizes you need — it saves time that would otherwise be spent grinding it down to get the right fit. Those sorts of adjustments can take days you can’t afford when your development cycle is on a tight deadline.

Once the CNC programming is done, it’s time to order the copper material for any EDM (electrical discharge machining) required by the design. This copper will be used to make the electrodes for sinker EDM.

The next material to prepare is the mold base. A mold base encloses the core and cavity parts of the mold itself and helps absorb the pressure from the injection process. The mold base is often made of a softer steel than the core and cavity because it’s cheaper than the harder steel used for those inserts.

And while we’re on the subject of mold bases, let’s talk about the interchangeable sort. Mold bases are often made in standard sizes that can hold a number of different mold cores and cavities. If you have a mold base available that was used for other projects, then you don’t need to spend the time or labor to make a new one. Some minor adjustments to that existing base may be needed, but overall, using an interchangeable base saves you a lot of time.

To finish off the mold materials list, the next step is to source all of the required off-the-shelf components — like screws, nuts, and bolts — plus anything else that’s on the BOM and hasn’t been obtained yet. This is also the time to order the plastic material.

China Manufacturing parts manufacturing partners stock general-purpose grades of plastic that are used most often and obtain other plastics from approved suppliers as needed.

If the plastic you need is a specialty grade, China Manufacturing parts, Inc. can source it for you. However, specialty-grade plastics can have longer procurement lead times and aren’t always available. Additionally, it takes longer for specialty plastic material to arrive than it does to machine the mold. So, it’s critical to determine early on if you’re going to use a specialty grade of plastic and consider ordering it before the part designs are finalized and the tooling order is released.

Once the material arrives, it’s time to start machining the mold. The core and cavity are machined from the prepared steel blocks, and the process starts with rough CNC machining using larger cutting tools to cut a rough outline.

Some manufacturers use less accurate (and therefore less expensive) machines to do this rough machining before moving the inserts to a high-precision machine. However, in recent years CNC machines have become more precise and less expensive, so the cost savings from using different machines to do rough and finishing cuts are now minimal.

Our manufacturing partners combine the rough and finish machining into one step and do both on the same machine, so they can make the cavity, core, and lifter/sliders in only a few days.

Machining itself for the Gantt chart sample part doesn’t take too long, less than one day. This method, combined with our program managers overseeing the schedule, also avoids time lost from the steel sitting in a queue waiting to be machined.

The copper blocks are also machined at the same time as the steel to ensure the EDM electrodes are available immediately to complete the mold.

After CNC machining the finer details into the mold components, the final touches are made to the geometry. This requires electrical discharge machining (EDM) to achieve certain geometries that cannot be created with a CNC mill. For example, wire EDM is used to cut gear teeth with sharp internal corners and square holes.

Then the cavity, core, lifters, sliders, and inserts go through the sinker EDM process using the machined copper electrodes.

Sinker EDM creates super fine details like text or internal features that are difficult or impossible to make with a CNC machine.

For this sample part, the cavity does not require as much EDM as the core side, so once finished, the cavity side can move directly to polishing to save time while the core machining continues.

Once the mold cavity, core, and other parts have been machined, it’s time to move onto the finishing touches, so we can actually manufacture some parts!

First, a fit check is in order. The two halves of the mold, the core, and cavity, are brought together to make sure they line up perfectly because any misalignment could result in flash or parting line mismatch. At the same time, some precision grinding is done on the mold parts to ensure that everything fits and meets the tight tolerances required.

After confirming that all the pieces fit well, the next step is to give the mold the right finish. This often means polishing it to a specified level of smoothness, or adding different textures when required. Whether or not the end goal is a polished surface finish, some polishing is always required to remove machining marks and provide a smooth surface upon which to add textures.

Finally, it’s time to assemble the mold and bring together the mold core and cavity, any sliders, lifters, or inserts, and the nuts and bolts that connect it all.

Assembly is usually done in the same 24 hours as the precision grinding, mold fitting, and polishing. Typically, China Manufacturing parts’s partners complete fitting by day and polishing by night.

Now, it’s time to shoot some plastic!

The first parts made with a mold are called T0 parts, and they show how the mold and all of the press parameters are working.

T0 parts are inspected for quality and indicate if any final adjustments to the mold or modifications in the press parameters are needed. For a small part, these tooling adjustments can be done in one day, while dialing in the mold for medium or larger parts takes two days.

The next parts to be shot are the T1 parts, which are usually the first parts to be shared with the customer.

Once the mold is loaded in the press, China Manufacturing parts’s supplier quality engineers and manufacturing partners continually monitor the process to ensure it’s delivering the quality you need.

Hopefully, you now have a better understanding of the many steps that go into creating a mold to manufacture your injection molded parts!

For the fastest lead time, remember 3 key strategies:

Combine those strategies with our Gantt chart template, and you can craft an efficient production plan for your next injection molding project.

If you don’t want to project manage all those steps yourself, our team at China Manufacturing parts, Inc. can help!

Every China Manufacturing parts, Inc. injection molding quote comes with a free DFM report and transparent pricing. Once your order kicks off, our team of program managers and quality engineers will ensure you get fully-inspected, high-quality parts in-hand, delivered on time, according to our rapid production timelines.

You can learn more about our injection molding capabilities here and then create your free China Manufacturing parts, Inc. account to request a quote!