Time to read: 2 min

Conventional manufacturing can be frustratingly opaque. To get visibility into production status, engineers and supply chain managers typically spend countless hours chasing down information. And when a critical build schedule is at risk, that’s the last thing you need.

We’re thrilled to share our new radical transparency features that deliver unprecedented visibility, traceability, speed and quality benefits for our customers.

Radical Transparency for a New Virtual World

In response to evolving customer needs and requirements, China Manufacturing parts’s radical transparency initiative introduces significant risk mitigation and cost-savings opportunities for large enterprises and small businesses alike.

The impact for enterprise companies trying to orchestrate production of hundreds of parts at once is enormous. “These new features on China Manufacturing parts’s platform are incredibly useful,” said Antonio Ruiz, Supervisor, Strategic Sourcing at NASA’s Jet Propulsion Lab. “Having 24/7 visibility and access to the real-time schedule of things is a game-changer.”

And for small businesses like Rise Robotics out of Somerville, MA, this level of visibility is truly unprecedented. “Everything is completely manual today,” said Blake Sessions, Director of R&D at Rise Robotics. “Having all this data updating live in one centralized place — part by part, order by order — is incredible.”

Available today, China Manufacturing parts’s digital platform offers these exciting new features:

On-Demand Production Status

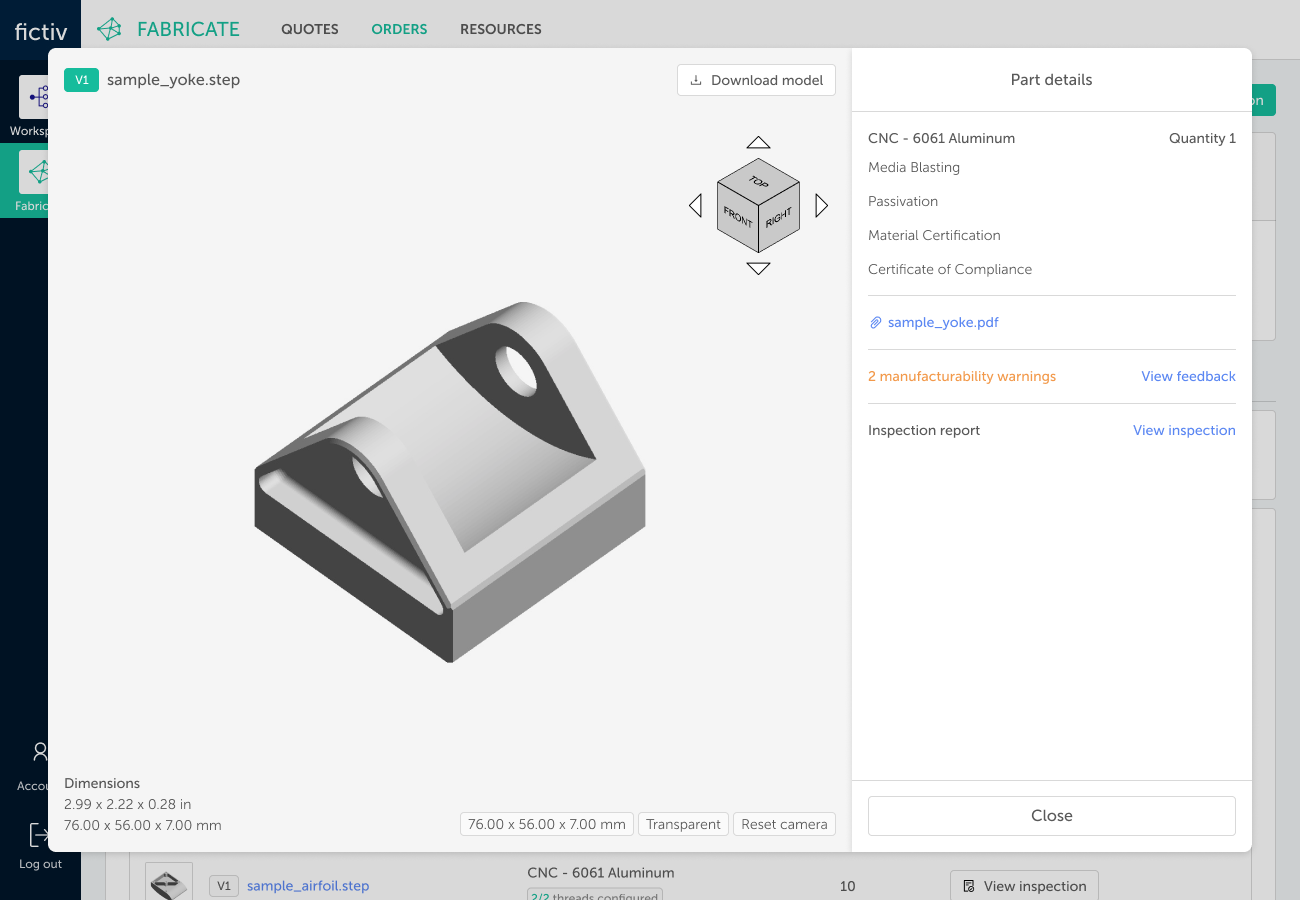

After placing your China Manufacturing parts, Inc. order, you’ll get a detailed view of the current production status of all your parts within every order — immediately and online.

The order tracker will automatically update as your parts go through various stages of production, quality inspection and shipping. And once your order ships out, you’ll find your third-party tracking numbers and shipping status, so you can follow your shipments every step of the way.

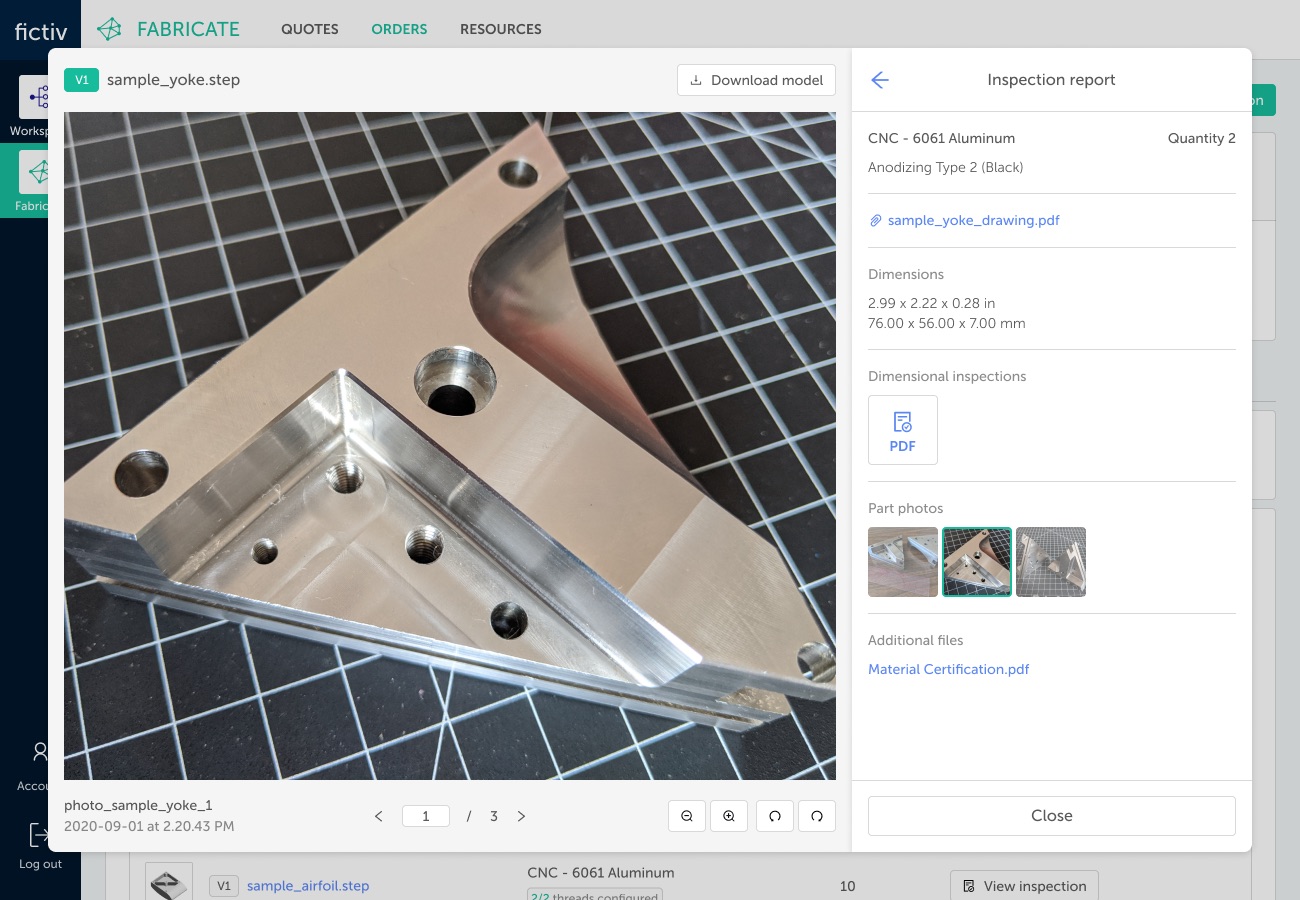

Virtual Inspection Photos

Once your parts have completed their inspections, you’ll now be able to see photos of your parts from the production facility — all before your order is delivered. You can also download inspection reports and any requested quality documentation, such as material certifications and certificates of conformance.

Centralized Access to Your Manufacturing Data

After your parts are delivered, our platform provides a secure place to access all your order data, making it easy to find design files, previous order configurations, DFM feedback, and reorder parts.