Time to read: 8 min

When you hear precision CNC machining, what do you think about? Isn’t all CNC machining “precision?” In a sense, yes. CNC machining allows you to make a lot of very precise parts relatively quickly. However, it goes much further than that. In this article, we’ll discuss what precision CNC machining is, how you to verify that your parts are precise, and how you can achieve more precise parts in your own CNC machining processes. You will also have an idea of what to look for when searching for precision machining services.

What Separates Regular CNC Machining from Precision CNC Machining?

Precision CNC machining sometimes is thought to mean that the parts made are very exact to the specifications/geometry of the intended design. That technically is not wrong, however the better word for this is accuracy. There is a subtle but important distinction between these two terms that we will cover in more detail in the next section. CNC machines are extremely capable and make parts that are sufficiently precise for many applications, but sometimes it’s not quite enough. When you add precision into the mix, you can take it to the next level. That brings us to the real question: what is precision machining?

So What Does Precision Really Mean?

Precision and accuracy are often confused and used interchangeably. Both of these are indeed related to quality, but they each have their own distinct meaning. Accuracy means close or exactly the target values (what a lot of people think is also the definition of precision). Precision is actually the ability to replicate consistent parts across a large number of produced units.

The key is that “large number of produced units.” Precision machining refers to many or multiple units. You can have one accurate part, but you must have many parts to measure and compare in order to call them precise. For example, if someone asks for a single part to be created using precision CNC machining, this is counterintuitive since “precision” in machining would involve multiple parts.

The graphic below is a good representation of the difference between accuracy and precision. If you are shooting darts at a dartboard, you may be able to hit the same area on the target, but it may not be in the center. This would be precise, but not accurate. This is an important point, because it is also possible in machining to make many parts the same, but not within your target tolerances! It is necessary to check for both accuracy and precision.

Now let’s talk about precision as it relates specifically to CNC machining. If you order some precision CNC machined components, what should you expect? Suppliers and machine shops should have processes in place to inspect your parts and make sure they meet certain quality standards. They will measure and compare a representative sample of the parts they produce to ensure complete these quality checks. The next section will go into more detail about some of these quality processes.

How Do You Know If Your Process and Parts Are Precise?

Measurement systems! Your measurement system is an integral part of, well, measuring and determining the quality and precision of your parts. When you want to improve a process, it is important to be able to identify and measure any issues. This can help you determine where the issue or error is coming from and how you can optimize it.

The first step is to make sure your measurement system is good enough. Is it measuring your parts accurately over and over again? (Accuracy and precision!) One way to check this is to use gauge parts and calibration to ensure that your measurement system is performing well. Gauge parts are parts that are machined extremely accurately to a known value. You can measure gauge blocks or pins for instance, then compare the value you get from your measurement system to the known measurement of that part. Gauge blocks can help with calibration of your measurement system as well, which is something that should be done regularly.

Some common processes used in development to find any measurement error are GR&Rs and MSAs. These are important to follow as they will help you collect good data that can be used to identify the error in your measurement system or parts.

MSA stands for Measurement Systems Analysis. By performing an MSA you can identify where the variation in your measurements is coming from. Is your measurement system consistent and reliable? Are the people who are taking the measurements doing so consistently? Are your parts being made with minimal variation? These are three sources of error that can lead to larger variations in measurement. If you identify that one is causing a significantly larger proportion of the variation, you can address that issue and know that you are getting good measurements.

GR&R stands for Gauge Repeatability and Reproducibility. This is a commonly used type of MSA. Repeatability refers to the ability of the operator to get the same measurement over and over again (on the same part). Reproducibility is the ability of another person to get the same measurement again and again. By identifying the variation within one person’s measurements and from person to person, you can identify the actual part to part variation.

To conduct a GR&R, you need 10 parts and 3 people to measure the parts. Each person will measure each part 10 times. With the resulting data, there are numerous analyses you can do to analyze your measurement system. You can calculate the components of variation as mentioned earlier: repeatability, reproducibility, operator variation, and part to part variation. You can look at an Xbar or R chart, which are graphical representations of variation by operator. In short, there are many ways to look at the data and figure out whether your measurements are precise.

Identifying these different sources of variation is so important in increasing the precision of your CNC machining process and parts. If you find that most of the error is coming from a lack of reproducibility, for example, you can focus on training operators rather than wasting time and money trying to improve your measurement system.

How Can You Improve the Precision of Your CNC Machining Process?

If we continue thinking about our hypothetical MSA, there is also the chance that your measurement system is not the problem. Maybe you are actually getting great measurements, but your parts are not as precise as you need them to be. There are many ways to improve the precision of your CNC machined parts.

A good first step is to think about your design from a DFM perspective. A lot of DFM principles will also contribute to the precision of your parts. The five design parameters to pay attention to are geometry, material, tolerance, part size, and look and feel (check out our DFM for CNC Machining Masterclass for more on this). The effort drivers for these parameters are also tied to precision – the more effort required to machine these parts, the more effort it is going to take to machine them with precision.

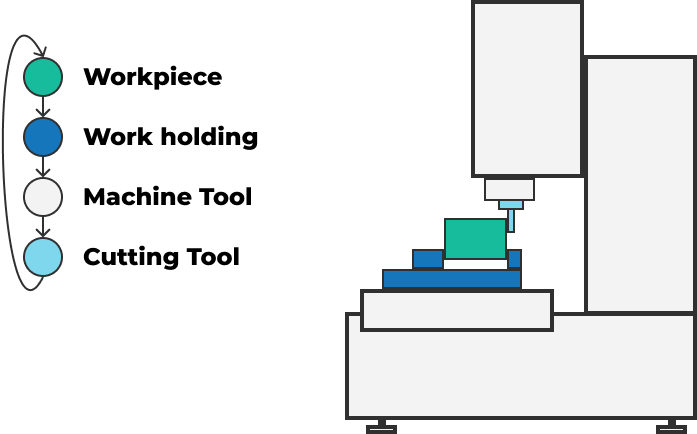

A particularly important aspect is tolerance. Precision machining is all about consistently staying within your tolerance limits. For instance, the stiffness of the entire system is a key driver of tolerance, and therefore precision. There is a line of compliance between the workpiece, workholding method, the tool, and the machine itself. If there are any reductions in stiffness along this path, it can lead to deflection and chatter, which in turn cause dimensional inaccuracies. To increase the precision of your CNC machining process, make sure your system (workpiece, workholding, tool, and machine) are optimized for stiffness.

Workholding is another important piece of the precision puzzle. Again, when we talk about precision, we are focusing on part to part variation. How are you making sure that every part is being placed in the exact position as the part before so that the CNC program will result in the same part? Your fixturing method is very important; it must constrain each part stiffly and in exactly the same position. One concept you can incorporate into your fixturing method is kinematic coupling.

Kinematic coupling allows you to constrain all six degrees of freedom of a part, without overconstraining it. This comes from the idea of exact constraint design, which says that the number of points of constraint should match the number of degrees of freedom you want to constrain. There are two types of kinematic coupling: Maxwell coupling and Kelvin coupling. A Maxwell coupling system has two parts: one with three v-shaped grooves on one part, all oriented towards the center, and one with three curved surfaces that mate with the grooves. On the other hand, a Kelvin coupling system consists of one part with one concave tetrahedron, one v-shaped groove, and one flat plate, and a mating part with three spherical surfaces. This is an important concept in precision engineering and could greatly improve the precision of your parts and CNC machining process.

![a graphic demonstrating Maxwell coupling, a type of kinematic coupling system with 3 v shaped grooves on one part and 3 curved surfaces on the mating part]()

Maxwell Coupling ![]()

Kelvin coupling

Why is Precision Important?

So far, we have talked a lot about precision: what it is, how you analyze your parts and process, and how to improve the precision of your CNC machined parts. Finally, I want to touch on why it is so important to spend valuable time and money on these steps.

Precision machining may be more important in some industries than others. Some parts or products need to be extremely reliable and work every single time. Take medical devices, for example. That surgical robot that the doctor is driving needs to do exactly what it’s told to do, with no lag, slip, or unexpected movements. Even a “simple,” everyday blood pressure reading is very important for the right diagnosis and needs to be correct every time. There is not a lot of room for error when it comes to people’s health.

The automotive industry is another one that needs precision parts. You want your car to drive reliably every day, right? And consumer electronics: you want your phone to be able to turn on and make a call when you need it to. Each of these products comes down to the interaction of many parts that need to fit and work together. This requires precise parts that are made the same way, every time.

If we think more upstream than the customer, precision CNC machining manufacturers care about precision too. An imprecise process is costly; it results in more scrap parts that don’t work, more rework cycles, more time, and overall more money! However, it is also important to realize when precision is not important. Fancy new measurement systems are expensive and require time and attention to set up and characterize, and you may needlessly add cost to your price by focusing too much on precision.

Again, CNC machining is an amazingly capable process that can instantly elevate the quality and efficiency of your parts and process. For some parts, it is important to pay extra attention to the precision component: are your parts consistently within the tolerance and quality that you need? Think about parts that you are currently working on. How important is precision in your specific application? How can you improve your design, machining, and measurement processes to improve the precision of your CNC machined parts? Check out Fictiv’s precision CNC machining services to learn more about how we can help!