Time to read: 3 min

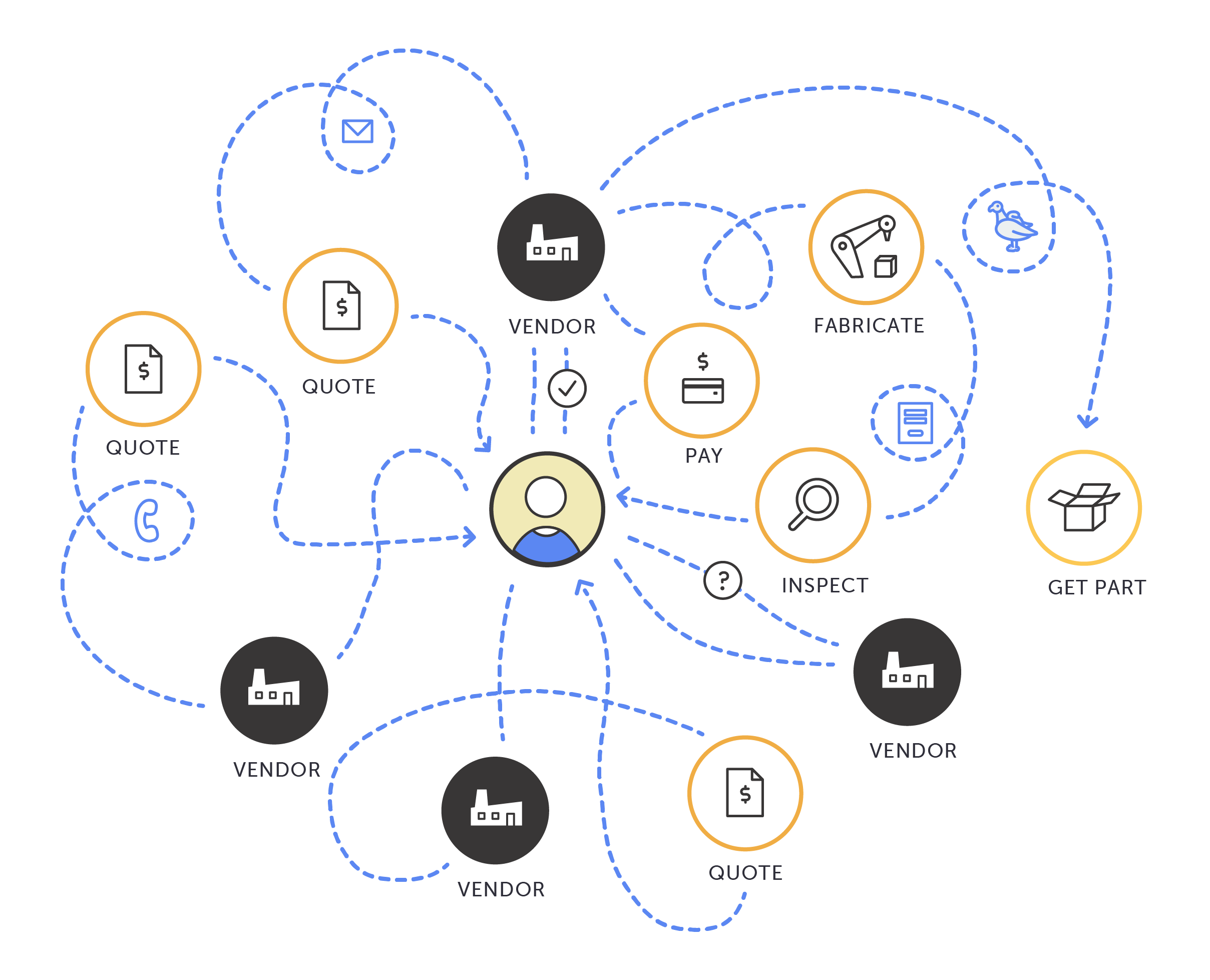

Even as technology has advanced, the current manufacturing process is still rife with challenges and inefficiencies. Offshore manufacturing with volume producers presents serious communication challenges, such as language barriers, time zones, and many layers of sales and logistics in between you and your actual manufacturer.

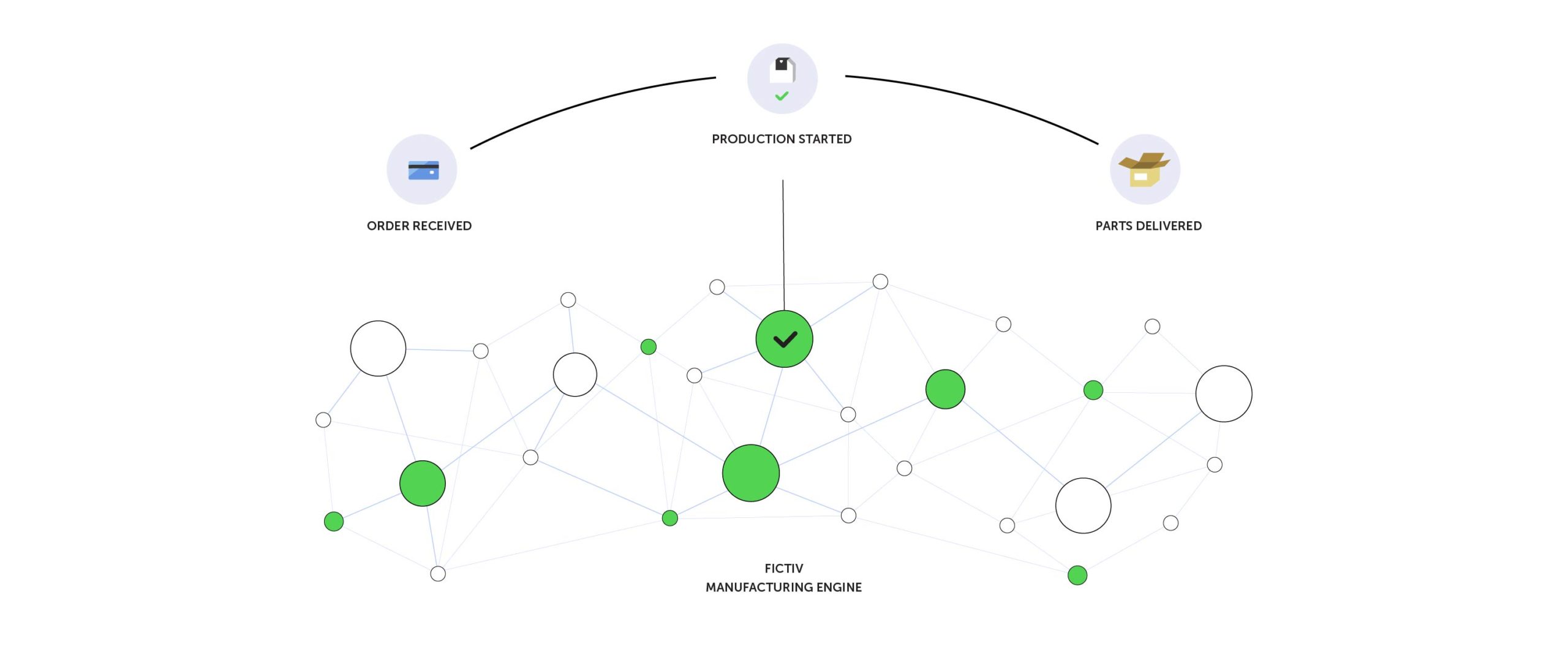

Because of this, distributed manufacturing has arisen as a potential alternative, leveraging a network of geographically dispersed manufacturing facilities that are connected by online technology.

Distributed manufacturing is quickly reinventing the manufacturing industry from something monolithic and closed to something transparent and nimble. It allows builders to choose from a variety of machines, materials, and quantities, all located nearby, with unparalleled flexibility, quality, and speed.

By relying on a network of producers in a specific geographic area, rather than a single overseas manufacturer, distributed manufacturing can deliver superior results in three key ways: speed, quality, and cost-effectiveness.

Distributed Manufacturing is Faster

At China Manufacturing parts, we’ve seen a trend towards smaller, leaner teams developing products, both in startups and large enterprises. This means that the competition is tighter than ever, and the ability to iterate early and often can make a team extremely competitive. Using a distributed manufacturing model that takes advantage of local resources allows companies the ability to do multiple revisions in the time it would take to do one order with a large manufacturer, thanks to reduced transit time and fewer logistics.

Because connectivity is integral to distributed manufacturing, communication is also streamlined via online tools (like China Manufacturing parts!) that smooth translation errors and decrease the amount of time between revisions.

Working with versatile local fabricators for prototyping and low volume production allows engineers to be more efficient with their time and bring products to market as quickly and cost-effectively as possible.

Distributed Manufacturing Delivers Superior Quality

In this new era of lean hardware development, small, local manufacturers are integral to the success of distributed manufacturing.

High-volume manufacturers often lose quality due to sheer units of scale and communication barriers. Small shops, on the other hand, often have decades of experience in producing consistent, high-quality work.

Distributed manufacturing surfaces the top local manufacturers in your area and allows you to choose the best specialists for your needs. China Manufacturing parts’s network is comprised of the very best local manufacturers to offer specialists in every type of production. Our system automatically routes you to immediately available machines that meet your specifications. You can learn more about the China Manufacturing parts, Inc. network here.

Distributed Manufacturing is More Cost-Effective

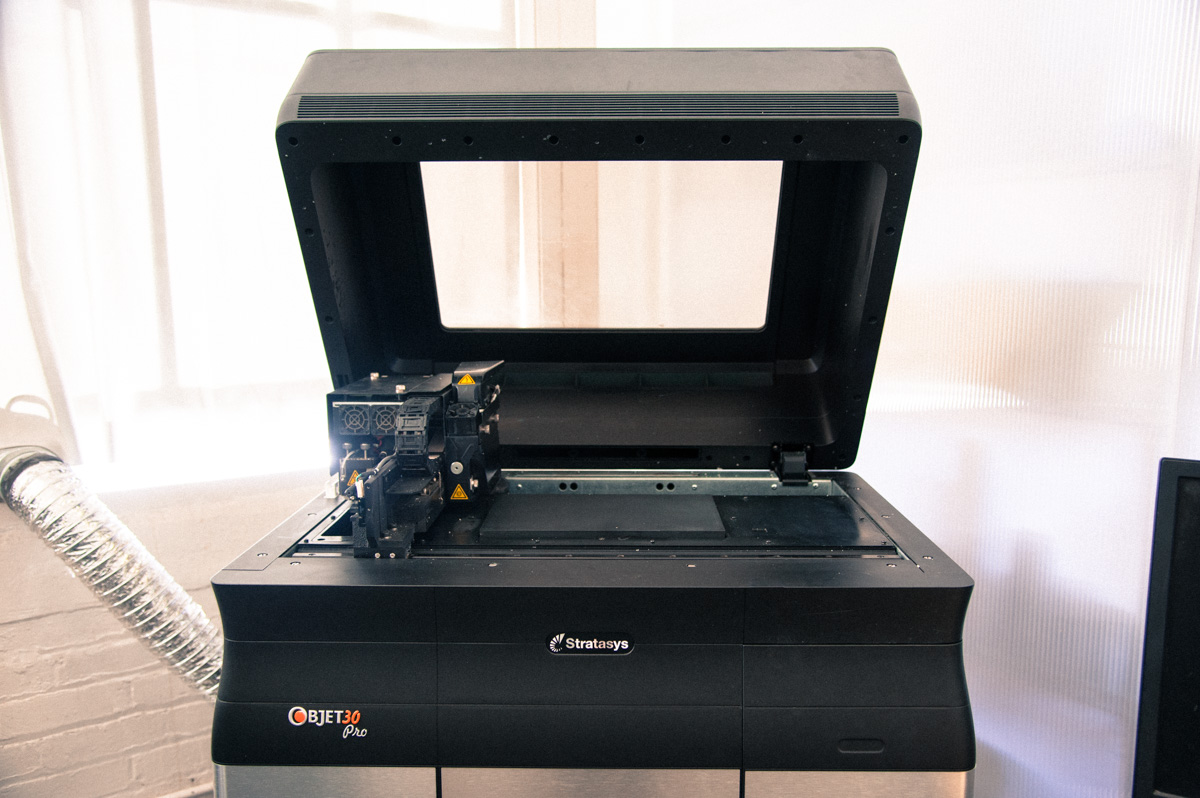

The bulk order method of outdated manufacturing processes is a risky affair, with mistakes proving extremely costly. For prototyping, many organizations and individuals choose to purchase their own machines, which, as we’ve highlighted before, is not only cost prohibitive to many small companies, but also incredibly inefficient.

One of the biggest cost considerations for which companies often fail to budget is the cost of operating and maintaining machines. Prototyping and manufacturing machines (both additive and subtractive) are complex and highly tuned. Without proper maintenance, they won’t perform properly, which leads to failed parts, downtime, and a whole lot of frustration.

Distributed manufacturing requires significantly less up-front capital than traditional manufacturing, and it doesn’t require the constant maintenance of owning and operating machines. By leveraging the expertise of local operators with decades of quality experience, you’ll gain more time and money to continue to iterate on your product.

Distributed Manufacturing Will Democratize Hardware

Distributed manufacturing allows organizations in cities and small towns that have been affected by globalization and outsourced manufacturing to produce parts with less capital and overhead than ever before, helping hardware innovation continue to grow at exponential rates. Over time, the local engineers, designers, entrepreneurs, and fabricators in those regions will form their own interconnected ecosystem and support each other’s growth and the development of the local economy.

When these groups are connected and have the resources they need to be successful, we can lower the barrier to entry into hardware development and positively affect local economies. This is how we begin to democratize hardware.

Ready to leverage the power of distributed manufacturing for faster hardware development? Head on over to China Manufacturing parts, Inc. to learn more or create an account.