About the team

Industry: Consumer Electronics

Product: Augmented reality projector

Location: New York City, Baoan, Romania

Why China Manufacturing parts

Customer challenges: Drawn to the content resources available at China Manufacturing parts.com/blog

Favorite features: Detailed design for manufacturability feedback for injection molding

Result: 500 injection molded beta units delivered in 4 weeks

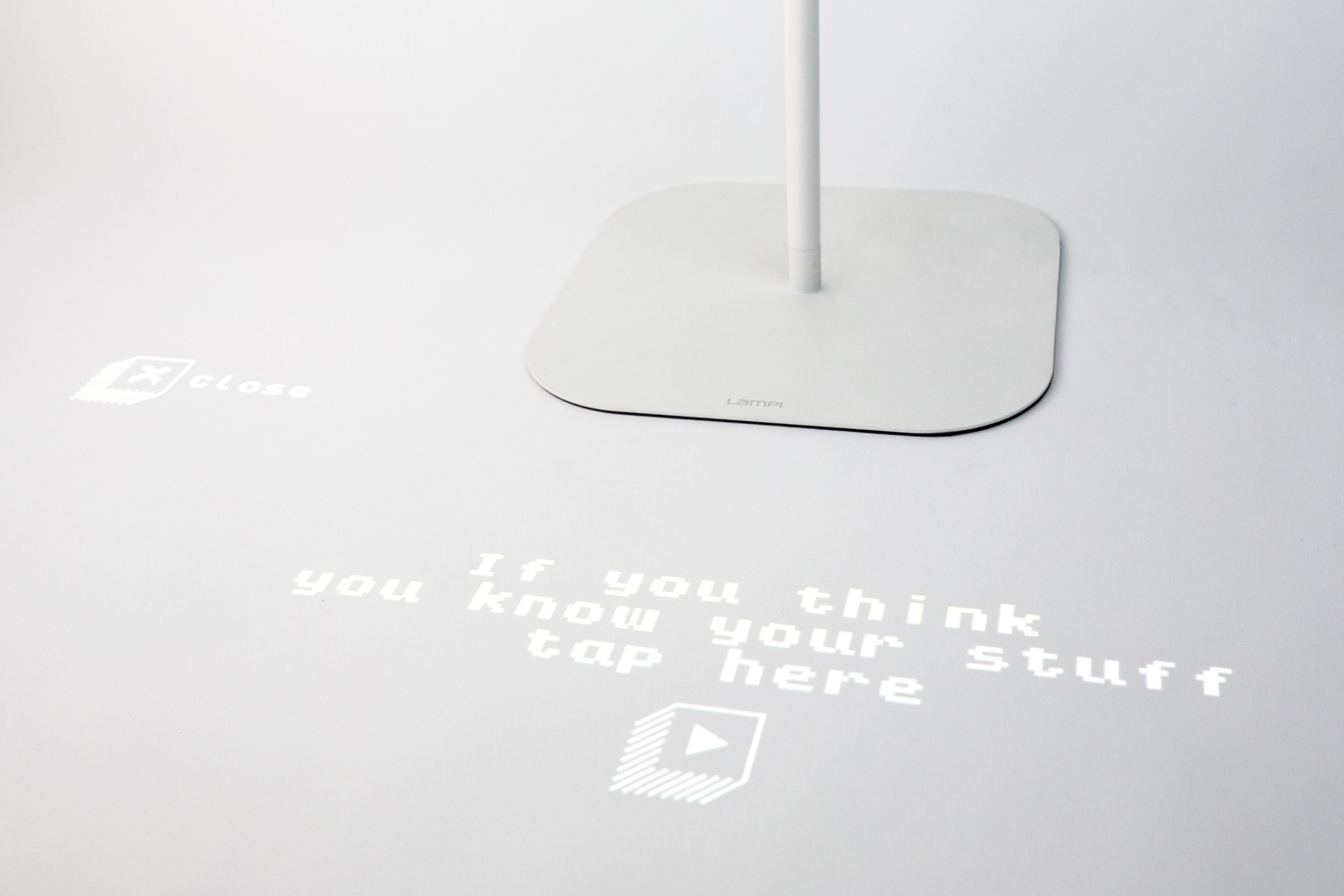

Lampix: An Augmented Reality Projector for Businesses

Lampix is an augmented reality projector in a lamp form-factor that can transform any flat surface into a dynamic AR display. The beta product contains a projector, camera and cloud-connected computer and leverages computer vision algorithms to identify real-world objects and project onto them.

The Lampix team is based in New York, Baoan, and Brasov, Romania and led by CEO George Popescu and CTO Mihai Dumitrescu. George is an MIT alumni with an impressive three masters degrees in computer science, electrical engineering and nanosciences, while Mihai brings deep experience in machine learning, neural networks, and computer vision from his own software development firm, Rosoftlab.

The Challenge: A Lean Hardware Team

The majority of Lampix’s resources are focused on software development rather than hardware, since the heart of its technology lies in machine learning and machine vision. For Hardware Lead Dzmitry Varhan, this meant he had to be very hands-on in both engineering and supply chain management activities which was time consuming.

“There was not much infrastructure support for hardware,” said Varhan. “I was the one who had to reach out to different suppliers, vet them and build out a network step by step.”

“It was definitely helpful to have China Manufacturing parts, Inc. manage relationships with the overseas injection molding manufacturer since we had a small hardware team”

It was also challenging to find manufacturers who were willing to produce lower volume injection molding runs.

“We were doing a 500 unit run, which meant we weren’t the focus for many manufacturers,” said Varhan. “It was challenging to find suppliers with strong communication skills and quality management systems that were willing to work with us.”

Partnering with China Manufacturing parts, Inc. for Supply Chain Management & Manufacturing Expertise

Varhan came across China Manufacturing parts, Inc. after discovering the wealth of content resources available for hardware engineers.

“China Manufacturing parts has a great website with tons of interesting content for people like me looking to learn new things,” said Varhan.

Varhan considered working with Protolabs for injection molding, but China Manufacturing parts, Inc. was able to match Protolabs’ lead time and beat their price. Additionally, China Manufacturing parts, Inc. provided detailed manufacturability feedback for injection molding during the quoting process.

“The experience was really great,” said Varhan. “Fictiv’s team in China provided me with a full DFM report with really specific, well organized comments, which I was able to review with China Manufacturing parts’s technical team based in Baoan and then make revisions on my designs.”

China Manufacturing parts was able to match Lampix with a vetted injection molding manufacturing partner in China to deliver T1 samples in just 21 days.

“It was definitely helpful to have China Manufacturing parts, Inc. manage relationships with the overseas injection molding manufacturer since we had a small hardware team,” said Varhan.

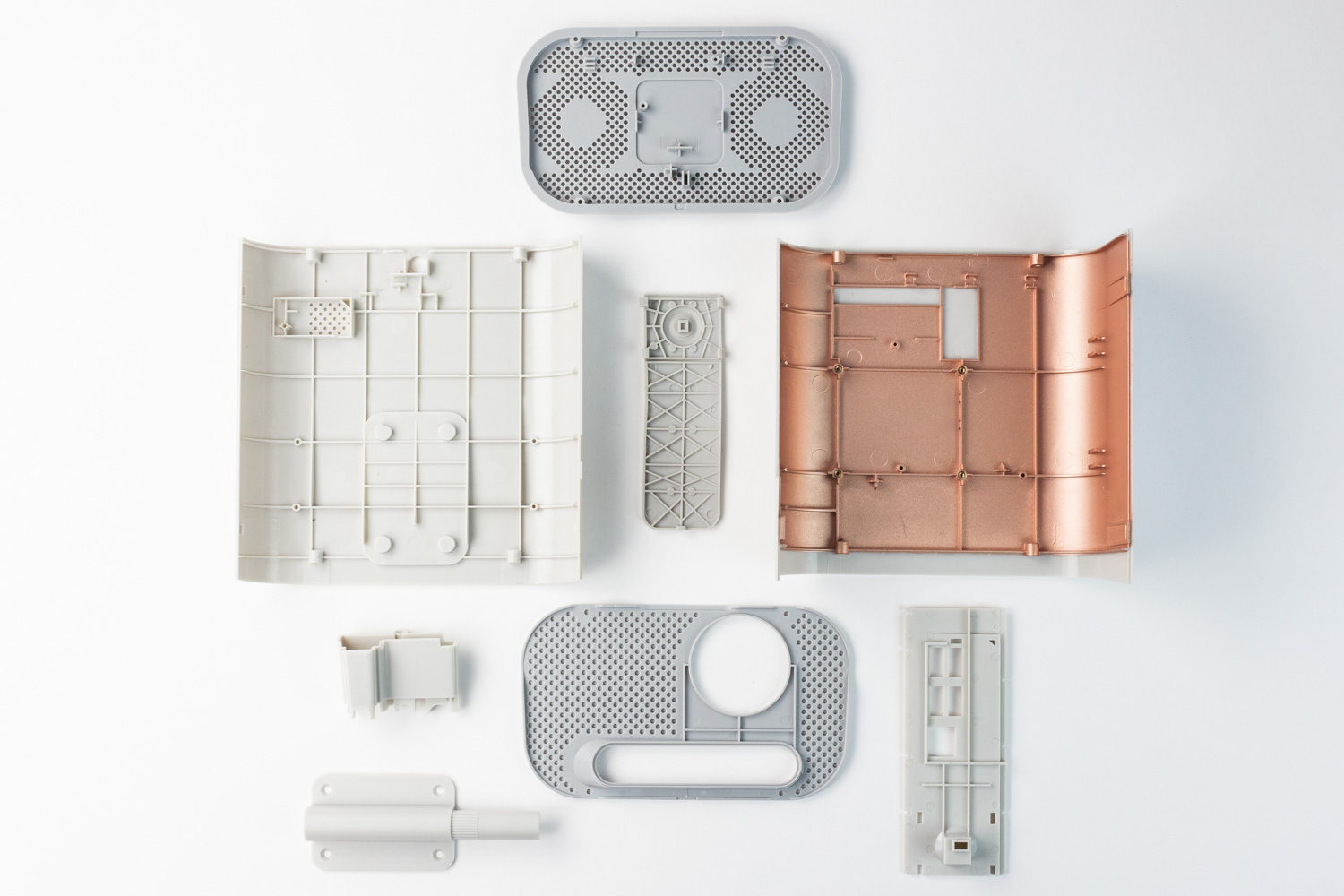

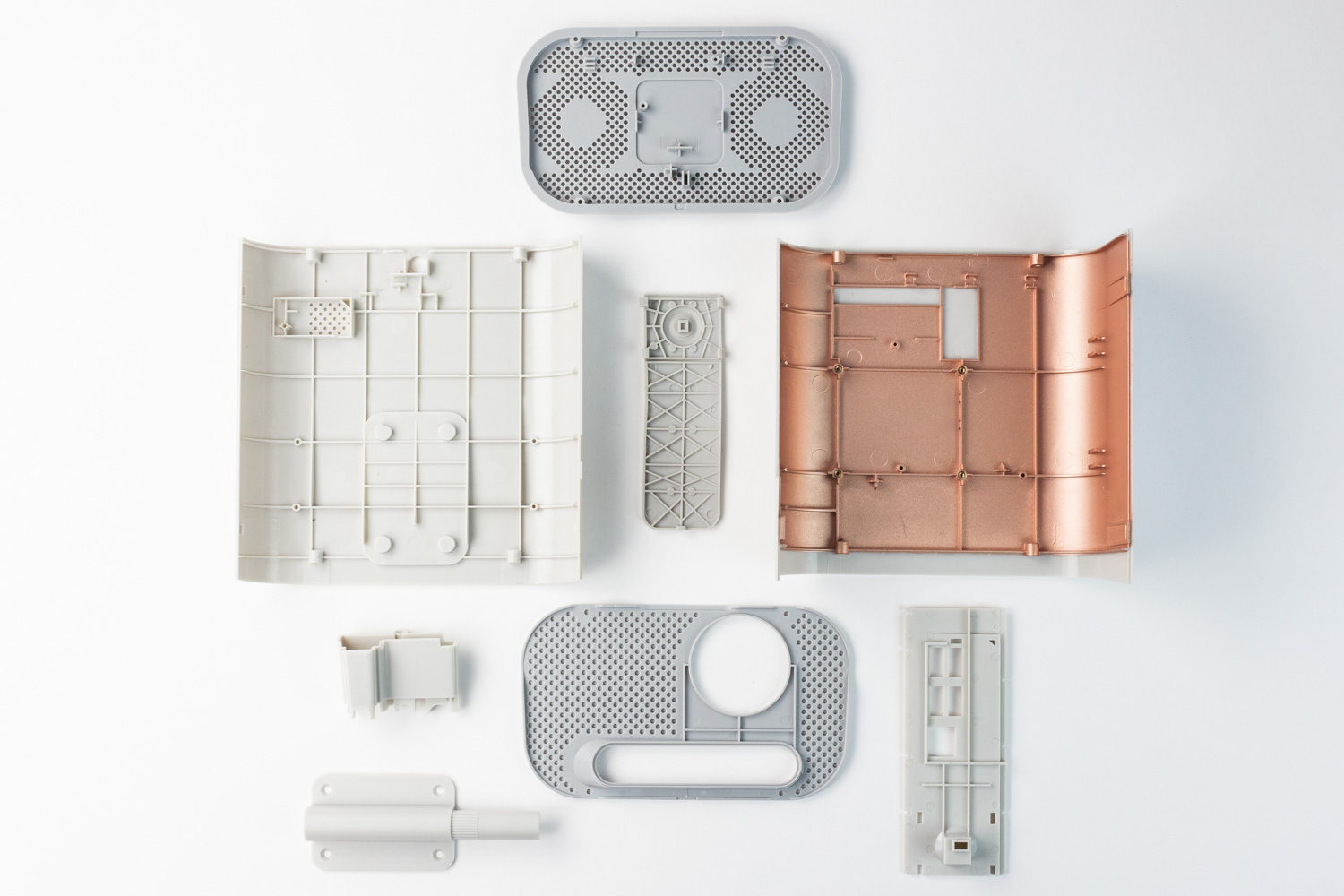

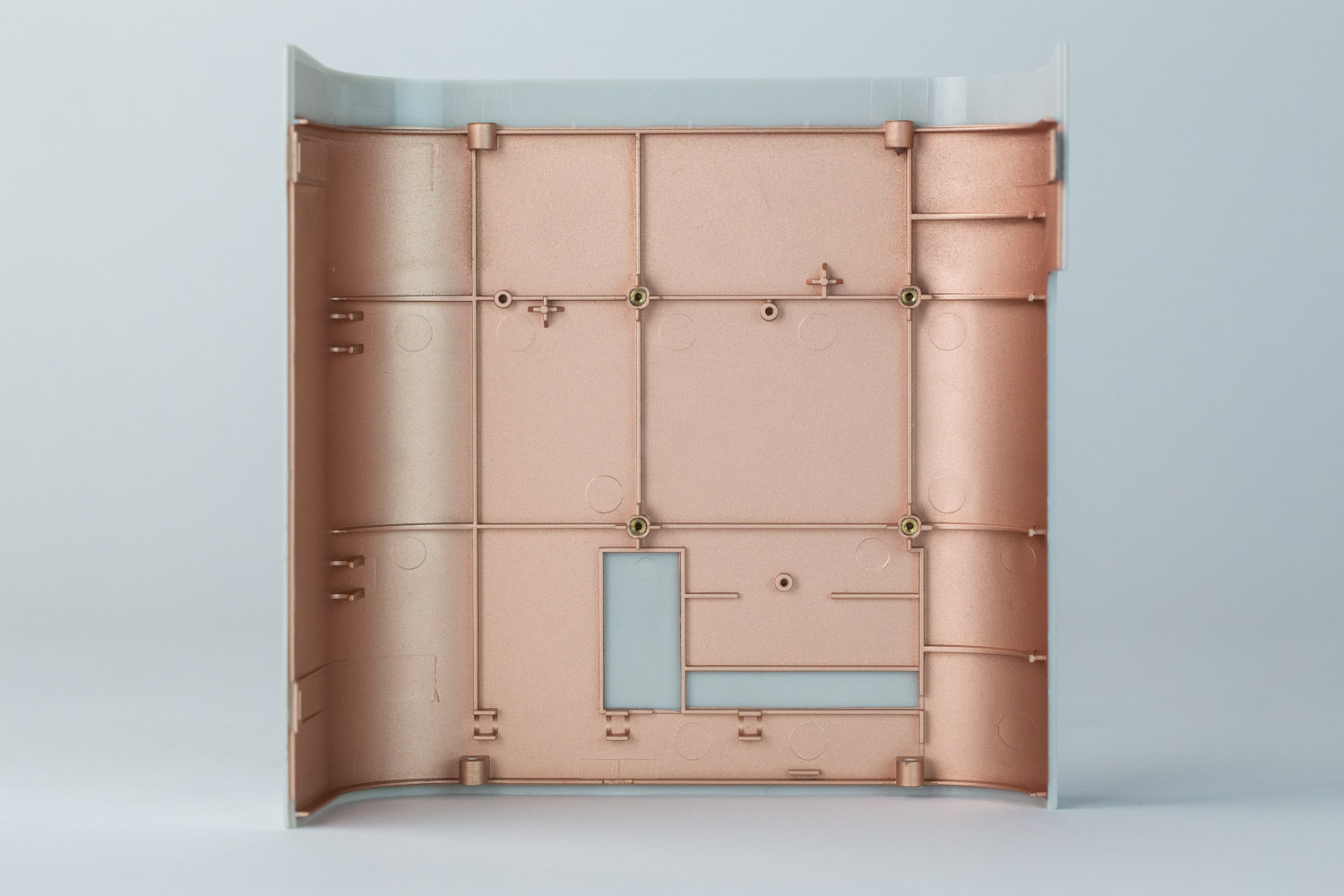

Injection Molding Part Design Features

Recessed undercuts

The Lampix parts required use of lifters and sliders to manufacture recessed undercuts in the parts, which increases the tooling complexity.

Flame-retardant material

China Manufacturing parts was able to help the team select a UL-94-rated, flame-retardant, premium ABS material appropriate for the design requirements.

Heat staked inserts

To streamline manufacturing, China Manufacturing parts, Inc. works with manufacturers that can perform injection molding and post-processing services in the same facility. These parts included heat staked inserts.

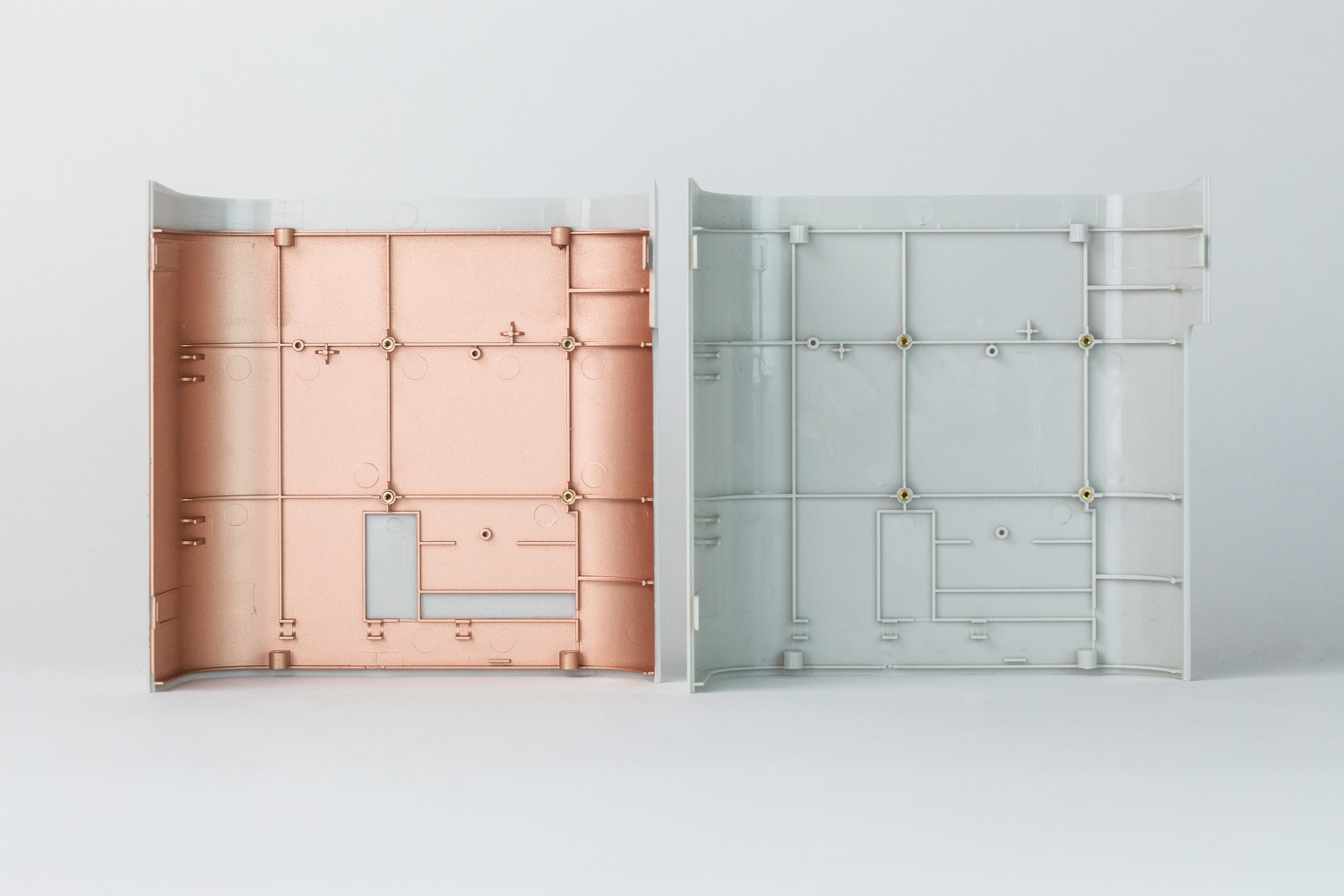

EMI coating

Two of the Lampix parts required a special electromagnetic interference (EMI) coating. China Manufacturing parts, Inc. was able to source a factory with experience working with this type of special coating, which helped the Lampix team pass the EMI certification.

“China Manufacturing parts has great pricing, great communication and they provide you with everything you need in terms of manufacturing and design feedback.”

To learn more about China Manufacturing parts’s injection molding capabilities, visit fictiv.com/injection-molding.