Dear readers, we have a special treat for you this week: The founder of Lockitron, Paul Gerhardt, came to China Manufacturing parts, Inc. HQ to help us tear down his latest keyless-entry smart lock: Lockitron Bolt.

Here’s a video to give you a behind-the-scenes look at the teardown and what Paul had to say about the product development process (for the full teardown, read the post below):

Anatomy of a Deadbolt

Bolt is a full replacement deadbolt lock, unlike its crowdfunded predecessor, which attached over the thumb turn on the inside of your door.

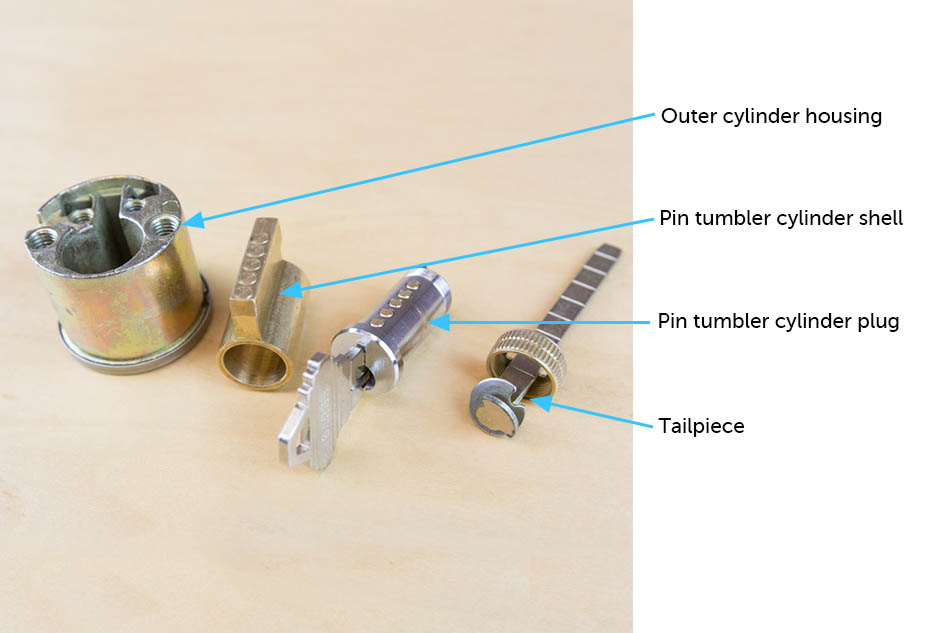

Bolt has all the building blocks of a conventional single-cylinder deadbolt:

1. Outside Cylinder Assembly

This assembly contains cylinder housing and a pin-tumbler cylinder, which is removable and re-configurable by a locksmith, so you can use your existing key. This feature was added especially for renters.

You can learn more about the pin tumbler mechanism here. Meanwhile, enjoy this awesome GIF:

2. Cylinder Collar/Cover/Guard

The outside cylinder collar that comes with Bolt is free spinning. This is actually a security feature typically found on higher-end locks: If torque is applied to the collar, it spins, rather than passing that torque onto the lock itself. This makes it much harder to wrench the lock out of the door.

3. Deadbolt Latch

The backset is the distance from the edge of the door to the center of the 2 ⅛-inch bore hole. In the U.S., you’ll find two common backsets, 2 ⅜” and 2 ¾”, which is pretty annoying when you’re trying to buy a new lock. Good news: The latch supplied by Lockitron is adjustable, and you can twist it to change it from 2 ⅜” to 2 ¾”.

Smart on the Inside

So far, none of these things are unique to Bolt; they’re actually all standard lock components. Let’s turn our attention to the inside of the door, where the real magic happens.

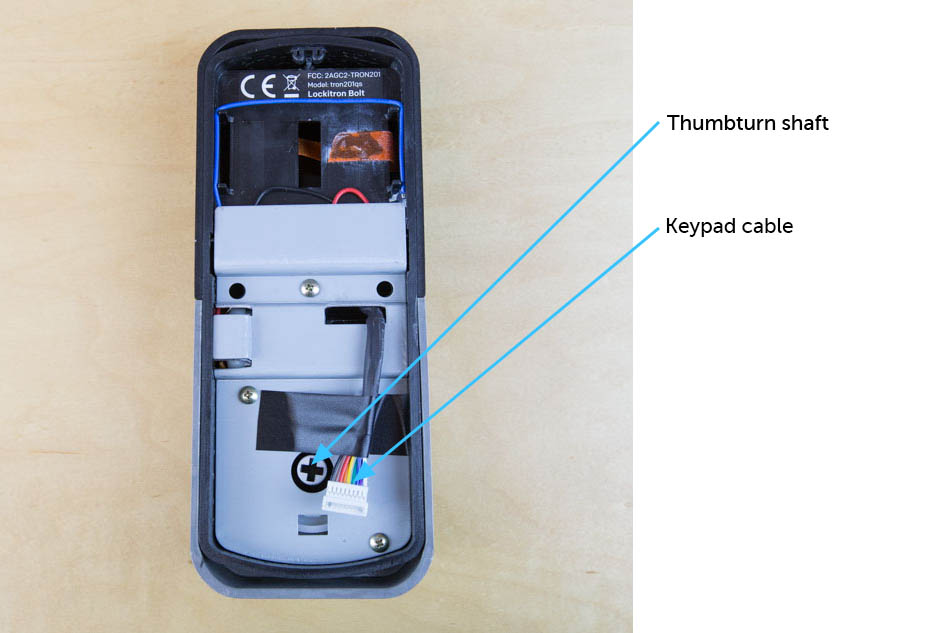

The rainbow-colored cable harness in the photo below is for future-proofing. Bolt is compatible with an outside keypad that’s scheduled to ship later this year.

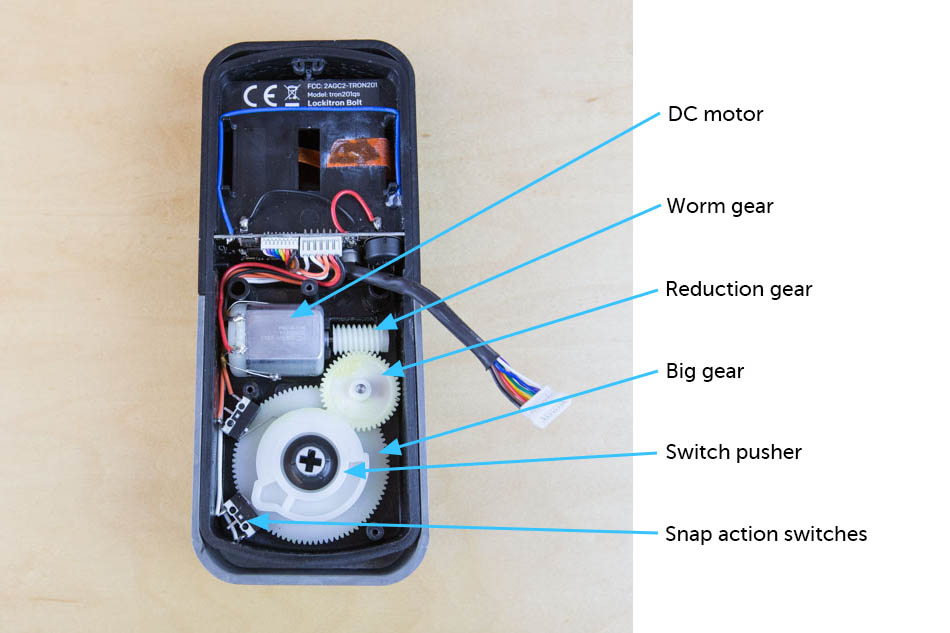

We removed the backplate to find the gear train that turns the deadbolt latch.

The “cross” you see in the photo is the backside of the thumb turn. The tailpiece that comes out of the outside cylinder goes through the a similar cross on the deadbolt latch and inserts into this cross.

When Bolt sets out to open the door, the DC motor spins to set off the unlock motion. The worm gear attached to the motor shaft drives a reduction gear, which in turn rotates the big gear.

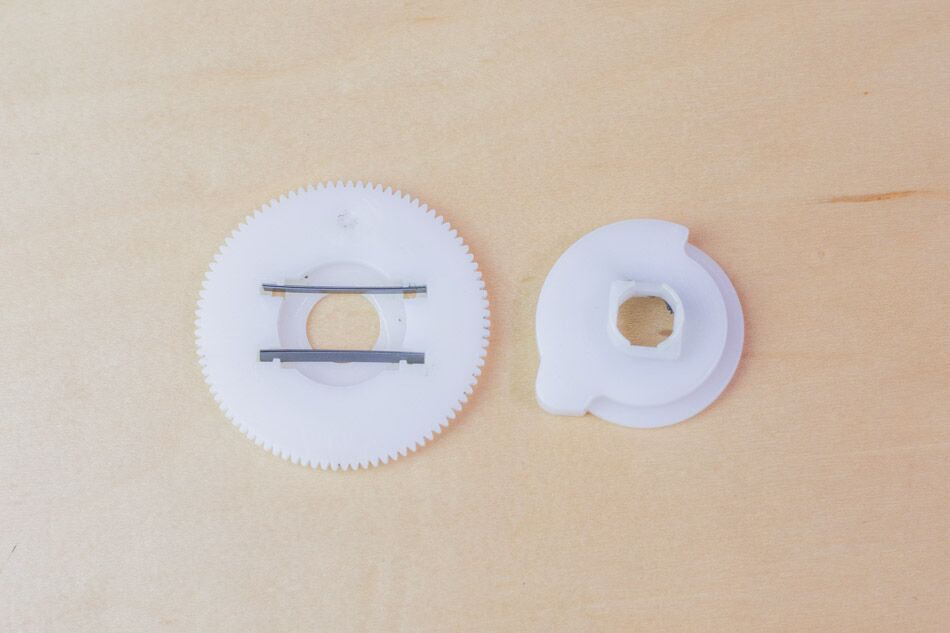

The big gear and the switch pusher are concentric, but they’re not both mounted to the thumb turn shaft—only the switch pusher is. Opposing leaf springs slotted into the big gear snugly pinch an almond-shaped boss on the switch pusher.

When the motor sets the gear train in motion, the big gear takes switch pusher and thumb turn for a spin. However, when you manually rotate the thumb turn from the inside, the switch pusher’s square corners overpower the leaf springs to open/close the latch. The big gear and reduction gear don’t move at all when this happens.

Remember, the worm gear cannot be back-driven, so without this clever mechanism, you wouldn’t be able to open or close the door manually.

We had to Dremel off a mean metal washer to reveal all these secrets. At China Manufacturing parts, we take safety seriously: Always wear safety goggles when making sparks fly!

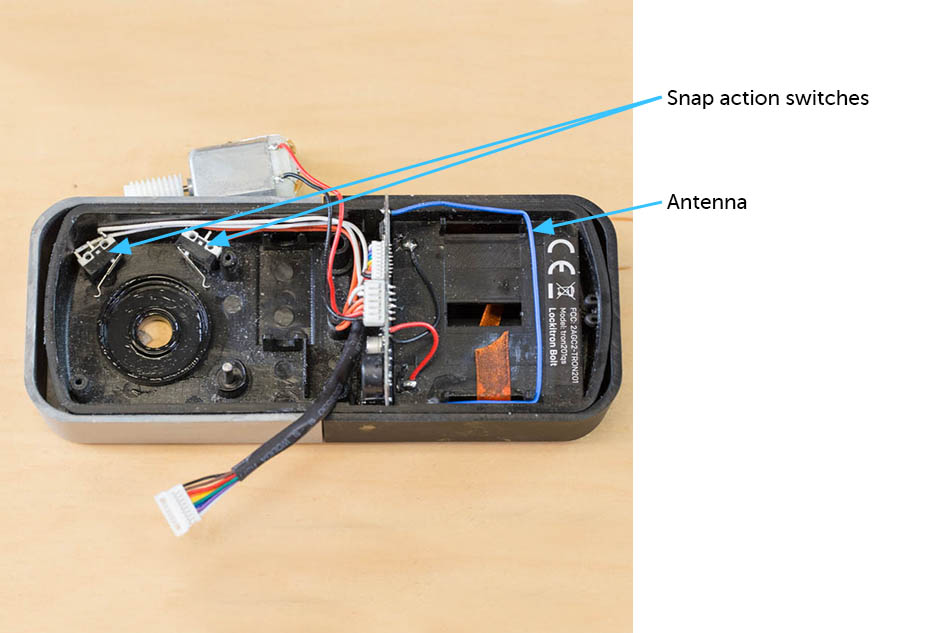

The snap action switches tell Bolt when the door is locked or unlocked. The blue wire is actually the Bluetooth antenna; how fitting.

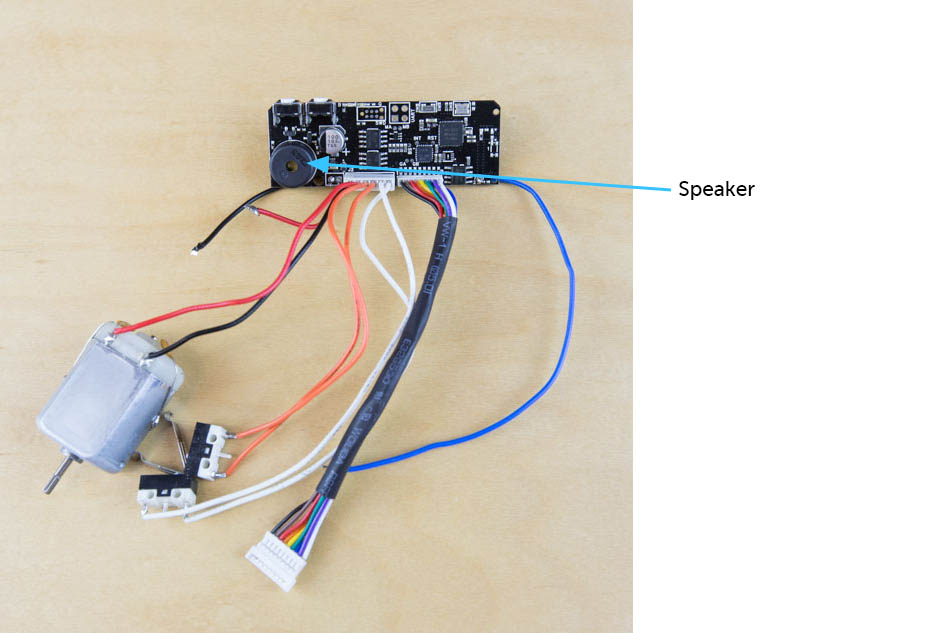

This small PCBA is Bolt’s brain. It’s got a small surface-mounted buzzer speaker for audible UX feedback.

The battery compartment features a ribbon to make removing the four AA batteries easier. It’s a simple feature, and Paul admits it’s a last minute addition, but it will definitely make the user experience smoother.

Construction

Lockitron Bolt has a lot of moving parts; however, lock components like the cylinder assembly, cylinder cover, and deadbolt are all off the shelf, sourced from conventional lock manufacturers.

The fewer custom parts you need, the less you have to pay for tooling. For a new product with low production volume, it makes sense to go mostly off the shelf and make as few custom parts as possible.

There are just ten custom parts in Bolt:

- ABS main housing

- ABS battery cover

- Delrin switch pusher

- Delrin worm gear

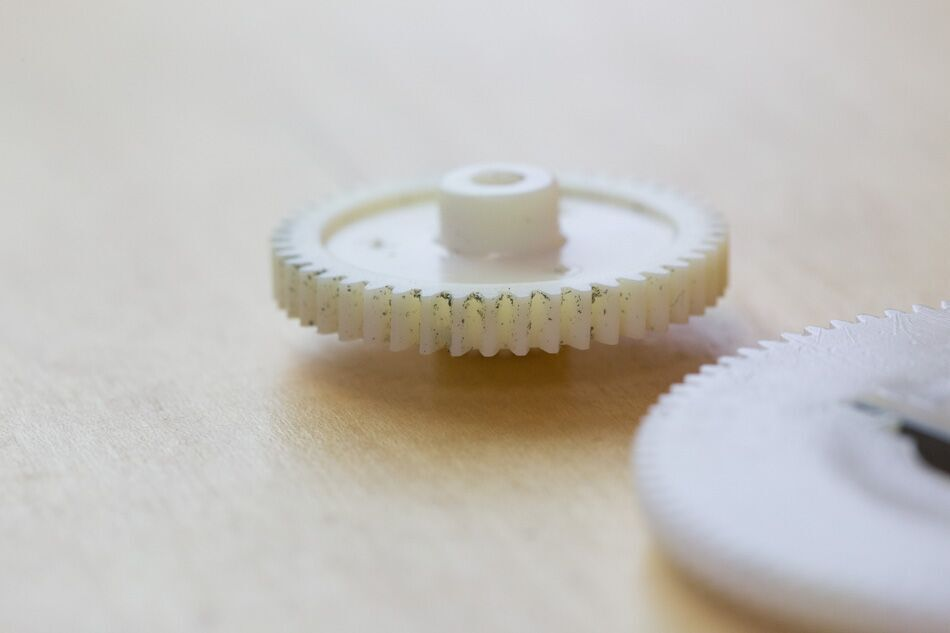

- Delrin big gear

- Hytrel reduction gear

- Cast aluminum housing

- Cast aluminum thumb turn

- Stamped steel mounting plate

- PCBA

Parts 1-6 are all injection molded.

The gears are helical and made with twist-off molds, which is more expensive than conventional straight-pull molds. However, this is the only way to mass-produce helical gears, which makes the gear train quieter.

On the other hand, the main housing and battery cover pieces are much simpler. Although the parts are large, they are simple and require few side-actions. The battery cover is a cosmetic component, and it gets a special coat of soft touch paint.

The cast aluminum parts are finished with CNC machining, bead blasting, and anodizing.

The steel mounting plate has a yellow zinc coating, also known as zinc-chromate conversion coating. This adds corrosion resistance and is ubiquitous in home hardware.

Lockitron Bridge

Bolt is Bluetooth LE only. If you want to lock or unlock Bolt over the internet, you need Bridge. Paul tells us that the removal of WiFi is motivated by two reasons: to lower the BOM cost and to extend Bolt’s battery life. Bolt is battery-powered only, but Bridge plugs into the wall via a micro USB to AC adapter.

Bridge’s black plastic enclosure is actually off the shelf—another smart way to save costs. In the best case scenario, the user won’t interact with Bridge after setting it up, so there’s no need to make a fancy enclosure for it. Lockitron customized the enclosure with a laser-engraved logo and instruction sticker.

The PCBA in the bridge features two familiar modules:

- The Electric Imp Wifi module with BlinkUp

- Bluegiga BLE112 bluetooth low energy module

Electric Imp has a great SDK and is easy to use for prototyping. BlinkUp is a quick and easy way to connect IoT devices to the internet. Check them out for your next project!

Final Word

Bolt is Lockitron’s third product, and the power of iteration really shows: It’s half the size of the crowdfunded Lockitron, and the design is much more polished. The previous version looked like a tech gadget, but Bolt has grown up and would look great in a sleek, modern apartment. In fact, Lockitron intentionally chose the colorways to match existing architectural fixture standards.