Time to read: 6 min

Casting – it’s been around for over 6,000 years and is still widely used today. Advances in casting technology allow the casting of high quality parts with tight tolerances. CNC machining is also pervasive, but much newer. Have you ever considered trying to CNC machine a part that you usually cast? Or are you wondering which method to choose to manufacture your design? This article will discuss the two manufacturing processes and go through the advantages and disadvantages of each.

What is Casting?

Casting is considered a formative process. There are many types of casting, but all of them use a mold. Molten metal is then poured or inserted into this mold, where it cools and hardens into the final form. Cores or inserts can create intricate internal geometry. After the part solidifies, it is cleaned and post-processed to give it the desired surface finish. Sometimes this secondary operation includes CNC machining to produce even tighter tolerances.

Some commonly cast parts include train wheels, bus pedals, turbine blades, and engine blocks. Cast parts are used in almost every industry, including automotive, aerospace, consumer products, and medical devices.

What is CNC machining?

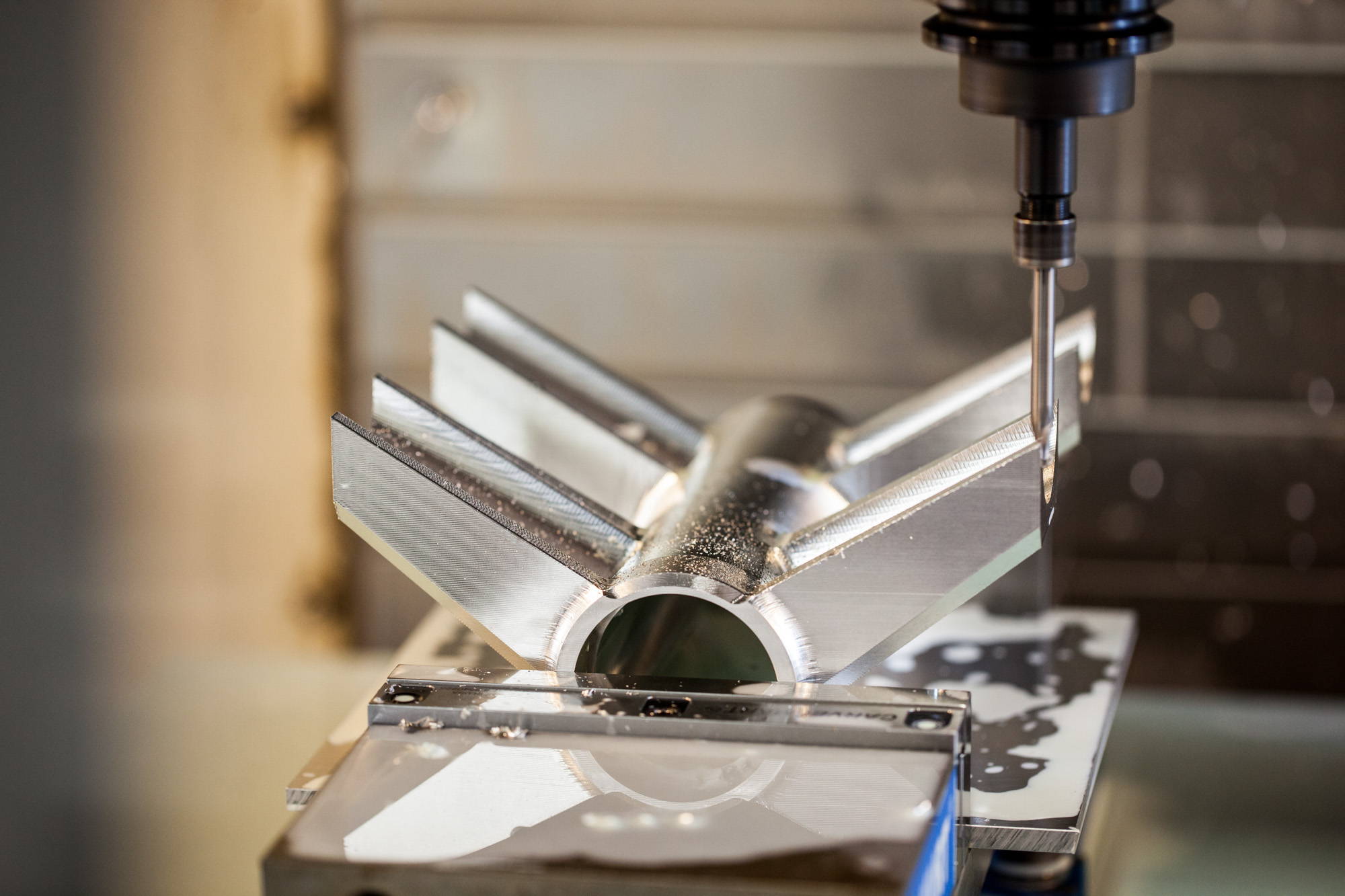

CNC machining is a subtractive method, which means that a cutting tool removes material to achieve the desired geometry. A computer program using G-code tells the machine where to move and how to cut.

CNC machined parts are everywhere. Metal laptop enclosures, small components inside cell phones, aerospace and automotive parts, as well as fixtures and jigs are all manufactured using CNC machining.

Choosing Your Manufacturing Method Based on Geometry

When designing a part, you often start with a manufacturing method in mind so that you can design realistic, achievable features that are well-suited to that process. On the other hand, the function of a part may require a certain size, shape, or geometry which will dictate the manufacturing process. CNC machining and casting are each suited to certain geometries.

For example, certain designs will require a large amount of material removal from an initial block of stock metal. This would take a lot of time and result in excessive wasted material, so this design might be a good candidate for casting. A good example of this would be a hollow part with thin walls and large cavities. Complex geometry is also a good candidate for casting, as this would require long and complex machining times.

Casting can be a good process to use to simplify the design of a part or assembly. Instead of machining many small parts and then assembling them, you can cast the entire part and avoid many assembly steps.

However, certain features are more difficult to achieve with casting. Undercuts or internal features will be more difficult and require complex molds with cores and inserts. Cast parts also require a draft angle on all features. Large or oddly shaped parts with thick walls are also better suited to CNC machining. These geometries will be difficult to fill and cool evenly during the casting process.

Advantages and Disadvantages

In addition to differences in geometry, the casting and machining processes have their own advantages and disadvantages.

Casting

Casting results in less wasted material. The casting process only uses the material needed for the final part, aside from a small amount of metal that flows through the gate, runner, and sprue. It is easy to remove this excess material and remelt it to reuse in another part.

Casting is also a fast process, once the mold is ready. This makes it good for producing high volumes of parts. Some types of casting do use an expendable mold. However, with die casting, which uses a permanent mold, the time and cost per part decreases as the volume of parts increases.

Repeatability is important in manufacturing, and casting produces very repeatable parts. With the mold and processed dialed in, every part can be made exactly the same. When die casting aluminum, tolerances can be held to +/- 0.25mm on up to 25.4mm, and 0.05 for precision casting (0.01” on up to 1” for standard and .002” for precision). This will vary depending on the material. Aluminum has a higher melting point than zinc, for instance, so it requires a higher injection pressure and is a more aggressive process overall. Therefore, even tighter tolerances can sometimes be held when casting zinc.

CNC Machining

CNC machining, on the other hand, has a quicker turnaround for a low volume of parts. There is no need to wait for the mold to be manufactured. All you need is the CAD model, CAM program, and a CNC machine.

Changing a design is much easier with CNC machining. When the design is still in flux, all you need to do is change the model and redo the CAM program, rather than remaking the mold or trying to modify it.

CNC machining is also an extremely repeatable process. For standard machining of metal, 0.025mm (0.001”) is a reasonable tolerance expectation. With precision machining, China Manufacturing parts can produce parts with tolerances as tight as +/- 0.0002”.

When to Choose One Process Over the Other

So, when would you choose casting over machining or vice versa? A few key things to think about are the development stage, the quantity of parts needed, demand variability, and part geometry, as covered earlier.

Development stage is tied to how much the design of your part is still changing. Earlier in the design process, you may be going through many iterations. In this case, CNC machining is going to be the better choice, due to the relative agility of changing a CNC machining process.

The quantity of parts you need is also relevant here. Earlier in prototyping, you may not need many parts, so again, CNC machining may make more sense.

Another thing to think about is the variability of your demand. How often do you actually need these parts? If demand fluctuates, CNC machining might be a better choice. You can get CNC machined parts much faster, especially with the growth of digital transformation. This can be a good financial choice, since you can order parts as you need them, rather than trying to predict what you’ll need and ending up with excess parts in inventory.

When you finalize your design and you move into production, you may need many more parts. At this point, casting is a good choice, because it is better suited to producing thousands of parts or more.

Finally, the quality of your parts is important. CNC machining is able to hold tighter tolerances on parts, making it a more precise process. Precision CNC machining can produce parts with a tolerance of +/- 0.0002”, whereas precision aluminum die casting is more like 0.002”. If this level of precision is extremely important to your application, CNC machining may be the better option for you.

Your manufacturing process will always come down to your unique opportunity. You may find yourself with a unique combination of requirements that forces you to be creative and find an innovative solution.

CNC machining has become such a pervasive process, but there is still a place for casting! Each manufacturing method has its own advantages. Rather than doing it the way it’s always been done, try reevaluating your design and see if it might be better suited for casting or CNC machining based on the part geometry, the quantity, quality needs, and your timeline.

Check out Fictiv’s CNC Machining Capabilities! Create an account and upload your part to see what our instant quote process can do for you.