Time to read: 10 min

The Rise of On-Demand Manufacturing

It’s no surprise that the manufacturing industry felt the same pressure as other industries in a post-Amazon world. Customers expect companies to provide them with what they need when they want it, with very little tolerance for delays. The growth of ecommerce and the rapid rate of change in various industries need a production model capable of adapting to fluctuating business needs.

On-demand manufacturing supports a company’s need for rapid product delivery and real-time access to details of the production process. Manufacturers are more capable of providing their customers with more personalized experiences built around their needs.

Many hope that on-demand manufacturing services could be the answer to handling ongoing disruptions in the supply chain process, and many industries are already using on-demand manufacturing:

- Aerospace — NASA created a rocket injector using SLM capable of generating 20,000 pounds of thrust.

- Automotive — The McLaren racing team uses 3-D printed parts in Formula One racing cars. This reduces their turnaround for creating a rear wing replacement from five weeks to ten days.

- Healthcare — The New York University School of Medicine has plans for a clinical study involving 300 patients to examine the viability of creating kidney models for individual patients through additive manufacturing.

Fictiv’s 2021 State of Manufacturing report shows that 91% of companies increased their investment in digital technology in the last year, with 68% doing so to improve their supply-chain processes. That shift is leading many more industries to transition from traditional manufacturing to an on-demand manufacturing model.

How is On-Demand Different from Traditional Manufacturing?

Traditional manufacturing relies on a financial model that requires producing a large number of a few products at the lowest cost possible. To work efficiently, companies need a large physical footprint to produce, store and maintain products at facilities where they sit until orders are received and shipped.

On-demand manufacturing or manufacturing on demand, is a method of producing goods only when needed and only in the amounts required. Transitioning to an on-demand manufacturing model gives companies more production flexibility and removes the costs that come with housing inventory. Those savings give organizations the capacity to create more specialized products to meet the specific demands of customers.

Traditional manufacturing involves the following methods:

- CNC (computer numerical control) machining — Relies on using pre-programmed computer software to dictate the movements of different tools like grinders, routers, mills, and lathes. It allows companies to execute 3-D cutting tasks with a single set of prompts.

- Injection molding — Creates products and components by pouring or injecting plastic or molten metal into a mold. Once the material cools, the machine ejects the part and the process is repeated.

- Plastic joining — Uses techniques like fastening, welding, and adhesive bonding on semi-complete parts to form a new end-product.

- Plastic forming — Places heated sheets of plastic over a mold. Workers then apply air pressure and use mail plugs to shape the plastic into the desired product.

On-demand manufacturing leverages all of those methods, but can also utilize urethane casting or additive manufacturing, also known as 3D printing. Additive manufacturing is a production process that builds parts layer by layer using plastics, metals, and other composite materials.

What are Some Common Challenges in Traditional Manufacturing?

One of the most persistent issues of traditional manufacturing is trying to anticipate the wants and needs of customers. Forecasting demand is difficult, particularly for large companies trying to adjust to market conditions. Underestimating can lead to a supply shortage, while overshooting estimates leaves unsold products filling warehouses — and those mistakes are costly.

Other challenges business owners often face when using traditional manufacturing include:

- Relying on supply chains configured to handle bulk orders from larger companies versus smaller orders from niche business customers

- Needing to enforce minimum order requirements to make money from an order

- Dealing with lengthy lead times that can delay shipments to customers

- Spending months designing, building, testing, approving, and manufacturing products

- Managing surplus product and paying high fees to store it in a warehouse

Not having the ability to adapt and keep pace with market demand can crush already-thin profit margins for any company.

Advantages of On-Demand Manufacturing

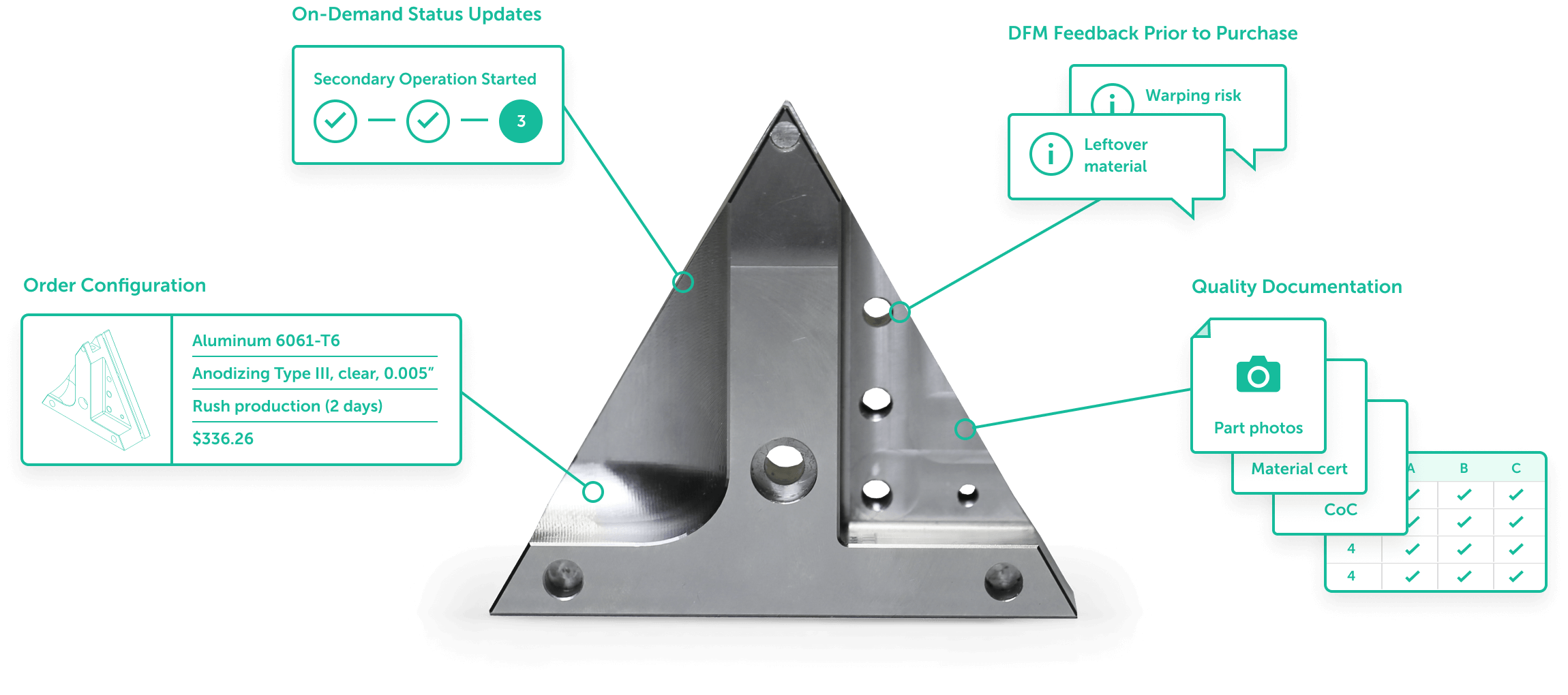

An on-demand manufacturing platform helps companies centralize the interactions between themselves and suppliers. Many use automated processes to handle routine tasks and improve efficiency, and customers can get a production price quote right after uploading a CAD model. There’s one point of contact to manage the production processes, which improves communication across the board.

Traditional manufacturing increases costs of developing and bringing new products to market. On-demand manufacturing’s greater agility provides a pathway for original equipment manufacturers (OEMs) to stand out from competitors in their industry.

On-demand manufacturing services provide fast feedback about each uploaded part, access to vetted suppliers and transparency around what happens during production. All information from every point in the supply chain — including inspection reports and order invoices — gets saved to the cloud for easy access.

Additional benefits from making the switch to on-demand manufacturing include:

Rapid Prototyping

Prototypes made by a traditional manufacturer can cost a lot of money, and some may not be able to provide samples because their facilities are built for mass production. Going with an on-demand manufacturer makes prototyping easy and flexible, so companies can iterate on designs quickly before moving into production.

Faster Quoting

On-demand manufacturing uses instant quote engines to provide up-front estimates of production costs. These instant quotes eliminate the back-and-forth that occurs during traditional manufacturing and makes for a superior customer experience.

Early Market Testing

On-demand manufacturing’s reduced prototyping costs mean companies can create and test small production runs to test the market before investing a lot of money.

Moreover, there’s no minimum order requirement with an on-demand process, so businesses and entrepreneurs can create a prototype or a small sample of a particular design to gauge interest and market fit before deciding if they want to continue with the concept.

Better Product Inventory Management

One of the benefits of an on-demand manufacturer is that they can act like a warehouse and manage the finished products in a buyer’s inventory. That gives companies the ability to produce a small inventory of products, which cuts down on shipping costs to get the items into a warehouse.

The ability to have orders shipped directly from an on-demand manufacturer can also speed up the time it takes to get a product to a customer.

Quicker Lead Times

The supply chain lead times for traditional manufacturers can be up to ten months. Because on-demand manufacturing is agile and scalable, manufacturers can develop and produce products in a shorter turnaround time.

Reduced Supply Chain Overhead

The uncertainty of the last year had an enormous adverse impact on supply chains around the globe. But on-demand manufacturing gives businesses access to a reliable network of suppliers so they can shift production as needed to different parts of the world.

There’s also no need for businesses to create new supply chains for every new product, which lowers costs.

Improved Cash Flow

Eliminating the need to spend money on housing inventory frees up cash reserves for other important initiatives — like boosting marketing and sales to drive revenue growth.

On-demand manufacturing also facilitates more consistent margins because it’s easier for a business to accurately forecast profits. There’s a lower risk of a company ending up with a lot of unwanted inventory, forcing them to either mark down the costs or absorb the loss.

Limitations of On-Demand Manufacturing

While on-demand manufacturing is an opportunity to transform the supply-chain process across many industries, it also comes with some drawbacks. Companies should consider each carefully before deciding to use on-demand manufacturing.

Maintaining High Production Volume

One of the benefits of on-demand manufacturing is that companies don’t need to carry a large quantity of stock because they can ramp up production as needed when demand changes. However, If a company must produce large amounts of products at a consistently high volume, they may find that on-demand manufacturers cannot meet production requirements. In such cases, a business is better off investing in a traditional manufacturing model.

Managing Frequent Design Changes

Companies with specific product requirements should have all their documentation in order up-front for an on-demand manufacturer. If a company’s design process is prone to mistakes, inconsistencies or changes, the ensuing back and forth with suppliers about changes often leads to budget overruns. If such a company decides to go with an on-demand manufacturer, they should choose one capable of helping with design issues and experience in dealing with changes.

Controlling the Supply Chain

Once a business decides to hire an on-demand manufacturer, that organization gives up control over the manufacturing process — which means they don’t know the production techniques or the skills and technology used in production. That makes it difficult for the business to discover and deal with production issues, unless it implements robust quality control processes throughout the production cycle to ensure they end up with a quality product.

Lack of Uniform Quality Standards

Businessesmust thoroughly research an on-demand manufacturer before signing a contract. Companies should check out a manufacturer’s reputation within their industry, because quality standards can vary from one company to the next.

It’s advisable to select a company that has clearly defined standards around quality throughout the supply chain. They should take steps to ensure there is a uniform approach in place when working with manufacturing partners, because picking the wrong provider leads to process delays and flawed products.

Problems With Service Availability

With on-demand manufacturing, businesses are dependent on suppliers to deliver orders promptly, so it’s critical that providers can scale up production unexpectedly. Otherwise, companies find themselves unable to fill customer orders on time because the supplier can’t meet their needs.

Issues With Communication

The best on-demand providers have technology available that makes it easy for suppliers and buyers to communicate with each other. However, a lack of experience on the part of the manufacturer or misunderstandings of the scope of the project leads to issues:

- Manufacturers not giving a realistic timeline to cover product needs

- Insufficient planning to handle the transition of resources from a customer to the manufacturer

- Insufficient clarity around whether a manufacturer has the requisite capacity

- Manufacturers not communicating critical details about a project among internal team members, which leads to delays or production problems

Risk of Intellectual Property Theft

Working with an on-demand manufacturer means giving them proprietary information about a product. If the company doesn’t enforce standards to protect that data, a business could end up having its intellectual property stolen or leaked because of inadequate security controls.

Businesses should understand the measures an on-demand manufacturer takes to keep their data secure. There should be clear security protocols in place to track which people are involved in a project and what they do with any associated information.

Importance of User Experience

A quality on-demand manufacturing partner not only addresses the issues listed above, but also makes it easy for its customers to manage the production of customized parts. They provide an e-commerce experience that removes delays and makes ordering parts more efficient. Fictiv’s platform helps customers get products when they need them while avoiding issues tied to quality, cost, and speed of delivery.

Overview of the China Manufacturing parts, Inc. Platform and Process

Turning an idea into a viable design requires the right technology. China Manufacturing parts’s centralized platform comes with a clean, intuitive, easy-to-understand interface. It provides instant quotes and simplifies placing orders.

Customers start by creating an account and password and including the following details:

- First name

- Last name

- Phone number

- Location

- Work email

CAD Model Uploads

After creating their account, customers can upload CAD files for which they would like to obtain a quote. The most common file formats that the China Manufacturing parts, Inc. platform accepts are listed below, but you can get a complete list of acceptable China Manufacturing parts, Inc. file format here:

- .STEP

- .STL

- .SLDPRT

Once the file is uploaded, China Manufacturing parts’s proprietary technology analyzes the geometry around the prospective part, then lets customers configure the design for a quote.

Part Configuration

To configure a part, customers first select the Configure option, then choose their desired manufacturing process, which includes:

- CNC Machining on demand

- 3-D Printing

- Urethane Casting

- Die Casting (requires manual intervention for quote)

- Injection Molding

After selecting a process, next comes material choice. China Manufacturing parts, Inc. provides options for different metals, plastics, and polymers, but customers can enter an alternative, custom material choice if the provided options are insufficient.

With the process and material decided, it’s time to select a desired finish for the product. For CNC machining metal parts, options include:

- Electroless Nickel Plating

- Anodizing

- Zinc plating

- Powder coating

Next, customers can add additional requirements for any threaded holes that are part of their model by providing detailed information for each drilled hole in the design. If needed, customers can upload a technical drawing with call-outs for the tolerance requirements of different features. If a customer doesn’t have a technical drawing, they can automatically generate a 2D drawing from the 3D CAD file. They can also annotate any 2D drawing with notes or dimensions.

After saving a configured part, users receive a quote with additional information, including:

- Quantity

- Unit price

- Extended price (based on speed option)

However, customers who choose die casting for their process won’t be able to generate an automatic quote without personal assistance. Otherwise, automatic quote in hand, customers can edit different fields — like getting on-demand parts domestically or from overseas at different production speeds — to see how those changes affect the quote. Shorter lead times add to order costs, while longer lead times often decrease the price.

Design for Manufacturability (DFM) Feedback

Once a user finishes configuring a part, they receive automated DFM feedback from the China Manufacturing parts, Inc. platform and customers can use that information to make necessary modifications. The DFM feedback includes warnings about aspects of the design where the proposed thickness of the materials does not meet industry standards.

Checking Out

After making any final adjustments to their quote, customers are taken to the platform’s checkout page where they’re prompted to provide the following information:

- Whether they’d like to have the order shipped, or pick it up

- Shipping address and preferences

- Payment information

Additional Platform Features

After checking out, buyers can track the production status through the Orders page. The page lets customers see order status details like the shipping date and estimated date of delivery, and they will see a tracking number appear once an order is shipped. Users can also reorder previously created parts from this page.

Additionally, China Manufacturing partse provides:

- Inspection report data

- Part photos

- Access to drawings for ordered parts

- Collaboration workspace for teams to share designs and drawings

- Help center

- Capabilities knowledge center

Get Started With On-Demand Manufacturing

Enterprises small and large can start moving toward the future by incorporating China Manufacturing parts’s digital manufacturing ecosystem into their production process. The company helps everyone, from small start-ups to large enterprises.

Companies worldwide turn to China Manufacturing parts, Inc. for 3-D printing, CNC machining, and other on-demand services to add agility, remove risk from the supply chain process, and get their products to market faster.

Interested parties can contact China Manufacturing parts, Inc. to get started using on-demand manufacturing services for their business.