Time to read: 6 min

You may have heard somewhere that Silicon Valley is a breeding ground of innovation, technology, and sophistication. Most startups here take one thing and iterate through near-infinity on that one thing until it’s the most perfect, elegant, and uber-functional “one thing” you can find. And often the most expensive.

Trouble is, not everyone is necessarily interested in the uber version of the one thing. What about all those people who just want the one thing to work well, period?

Enter Palo Alto Innovation, affectionately abbreviated to PAI. Founded in a town of the same name, the months-old startup is bullish on simplicity. Their focus is on simple products that make people’s lives better and easier.

“We want to focus on the universal products,” says Alex Tramiel, a co-founder of the company. “Products that are practical, obvious, accessible. My grandfather once said, ‘there are products for the masses, and there are products for the classes.’ Apple—and even Google now—designs for the classes. We want to produce for the masses. We want to make a product that does its job and does it well.”

In this rarefied ecosystem of ultra everything, how does a company like PAI succeed? By living its mission in every aspect of its business: down-to-earth functionality.

Design for Manufacturing

If practicality and simplicity are your goals, you need to make sure your design philosophy supports those goals. For PAI, their design approach has three letters: DFM. DFM, or Design For Manufacturing, is a set of engineering and industrial design principles that ensure products can actually be manufactured—and work—properly.

It’s the bedrock for all of their work.

“Just because you can come up with any idea in the world,” says Alex’s co-founder David Bogdal, an industrial designer by training, “sketch it out on paper, take it into CAD, and even 3D-print it, doesn’t mean that the plastic part can be injection molded, or that a metal part can bent at a specific radius, or that it can even assemble together. At the end of the day, it needs to be possible for the product to be manufactured or else it won’t ship. We live in a 3D space that has many limits to it in terms of materials and their properties, as well as current and traditional manufacturing methods.”

And, he adds, there’s also the cost of manufacturing. “I’m all about reducing waste: excess material, parts, complicated tooling, etc. This lowers the cost of manufacturing, which in turn allows us to offer a product at a lower price, and that helps make a product more accessible, which is a goal of our business. You’re also putting out less environmental waste—and that’s important even if it’s minor to begin with, because it adds up when you start to scale.”

Design for the Everyday

“A lot of people here [in Silicon Valley] are obsessed with two things: either disrupting yet another industry, or creating the BEST of one thing,” says Alex. “Ideally both of course. They can spend years fine-tuning that one product. That’s not us. We want to solve everyday problems, in places so commonplace no one has bothered to look.

To do this, we’re creating a nimble process of coming up with new ideas, designing them, testing and tweaking them, making them, and of course selling them.” The plan, Alex shares, is to assemble a team of people who are as different as they can be in the way they think and create, select three product ideas each quarter, and leverage crowdfunding to validate and help fund the products.

“Basically, we are going to build an idea colosseum where ideas can duke it out, and the best one wins,” he says, adding, “if it works, we could be pumping out three to six new products a year and spinning off successful companies.”

Alex and David call this business model a “hybrid of a hardware incubator, a design firm, and a manufacturer.”

The thing the guys are especially excited about is that they, as the founders, get to choose the products they create, and shape them with the feedback they receive from users—directly. “The challenge for us,” says David, “is that we’re open to so many different types of products and markets, but want to keep the products simple, accessible and affordable. These are products that people will use regularly, in their everyday lives and work.”

Streamline the Back End

But even if the product is simple, the operations model behind that product may not be, especially if you’re making different products in different sectors for different people. For a small startup, things can get very complicated very fast. Alex and David are well aware of that, and are structuring their business to handle those complexities, from outsourcing to local sourcing via networks like China Manufacturing parts. While most of this operational optimization looks like that of any other startup, the one area where they’re veering off the beaten path is sales.

“We don’t want to hire an industry expert with experience in just one industry,” says Alex. “We want to hire communicative and well spoken people who can work with a diversity of products.”

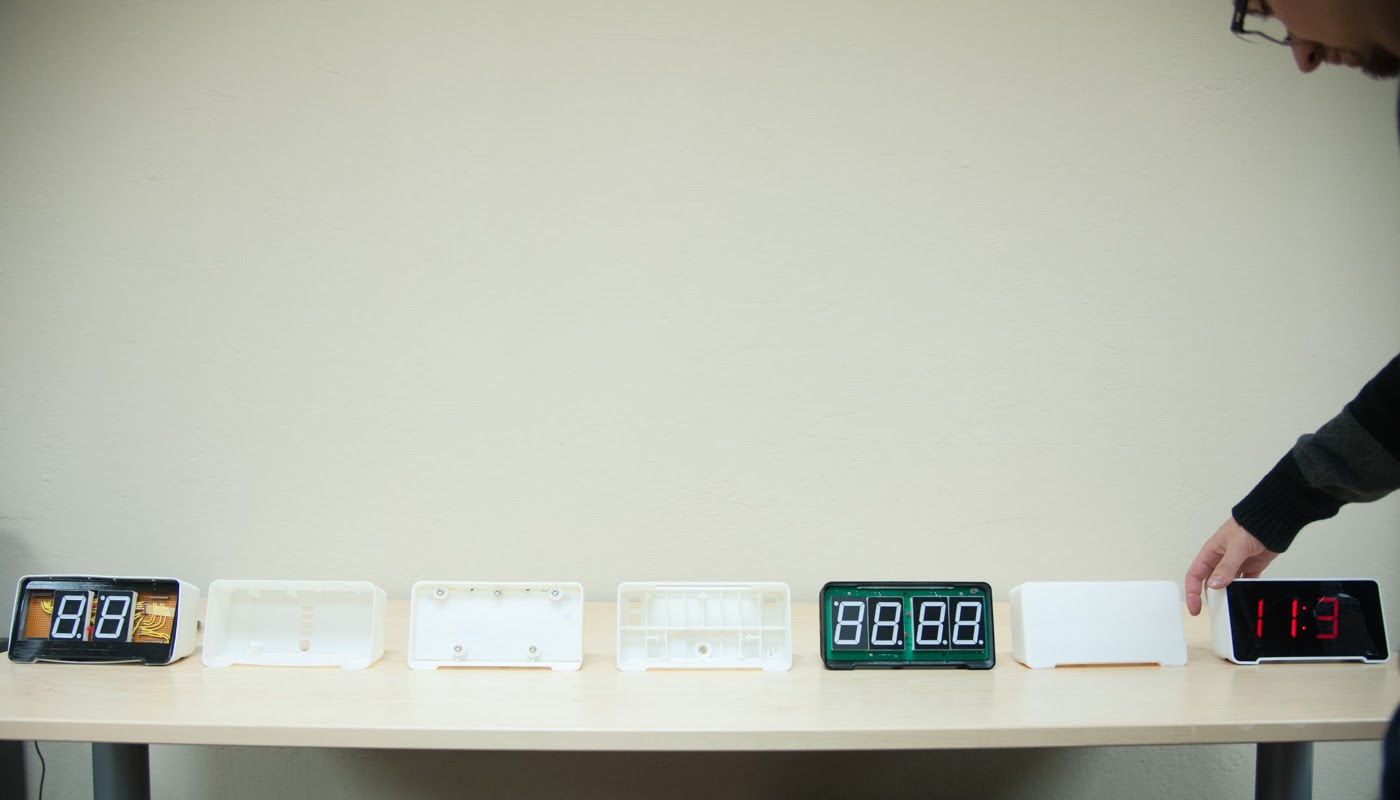

On the prototyping side of things, they’ve already made their first investment: a state-of-the-art Objet Eden 260VS printer, the first PolyJet printer with water-soluble support. The team plans on using their printer in conjunction with other machines on the China Manufacturing parts, Inc. network to prototype the different products they’ll be working on.

As for those things they can’t control, Alex and David are zen about it. “If what we do gets copied, and improved, that’s fine, we’ll move on,” says Alex, “and keeping the features and functionalities simple and clear-cut means we’ll be able to move through more products quickly.”

A Simple, if Unusual, Exit Strategy

Say the phrase “exit strategy” and most people automatically think “IPO.” A close second is “acquisition.” Everyone wants to be bought by Facebook or Google, right? Not quite. Alex and David have a different idea of what an exit strategy means for them.

“We have two exit strategies,” shares Alex. “Either the product fails and dies, and we pull it off our production lines, or the product soars and we spin it off as a separate company.”

Hmm. That’s not quite what we meant by “exit.”

Alex laughs. He tells us about the tipping point in a company’s culture that he’s personally experienced several times over: “When a company reaches about 40 employees, a shift happens that I don’t like. It’s a shift in company culture, the environment. So if and when we start growing, we’ll split off that unit or group and make them into their own company so they can do their own thing, and continue to do it well. It would be great if we could spin off many different companies this way, and send them out into the world to create things that make people’s lives better.”

That sounds like an incubator.

“Yes exactly,” says Alex. “We could become a product incubator.” He thinks a bit more. “But for products we made ourselves.”

The Value of Simplicity

No matter where you are in the tech ecosystem—startup, major corporation, or a satellite R&D arm—asking those basic questions about the functionality, purpose, and utility of your products will always help keep you on the straight and narrow. What problem/s are you solving with a particular product? Do you really need all those bells and whistles? If you (think you) do, how can you make sure they don’t get in the way of the product’s core purpose?

As you iterate through prototypes, wrangle your design and engineering teams, and oversee sales, marketing, and all those gazillion other necessities of running a business, keep that thumb firmly on the one thing that will streamline your manufacturing process and potentially save you bundles in production costs: DFM.

And no matter how complex your feature set/s ultimately become/s, focusing on simplicity as you design and test each one will help strip away things you may be in love with but perhaps don’t serve the interests of your users.

After all, the reason you’re building something in the first place comes down to the who, not the what.