Time to read: 5 min

Star Wars enthusiasts around the galaxy were captivated by the debut of the new, spherical droid BB-8™ in 2015’s The Force Awakens and subsequently rushed to purchase their own little droids, made by Boulder-based Sphero. Now, fans are eagerly snapping up the new BB-9E droid and the beloved classic, R2-D2.

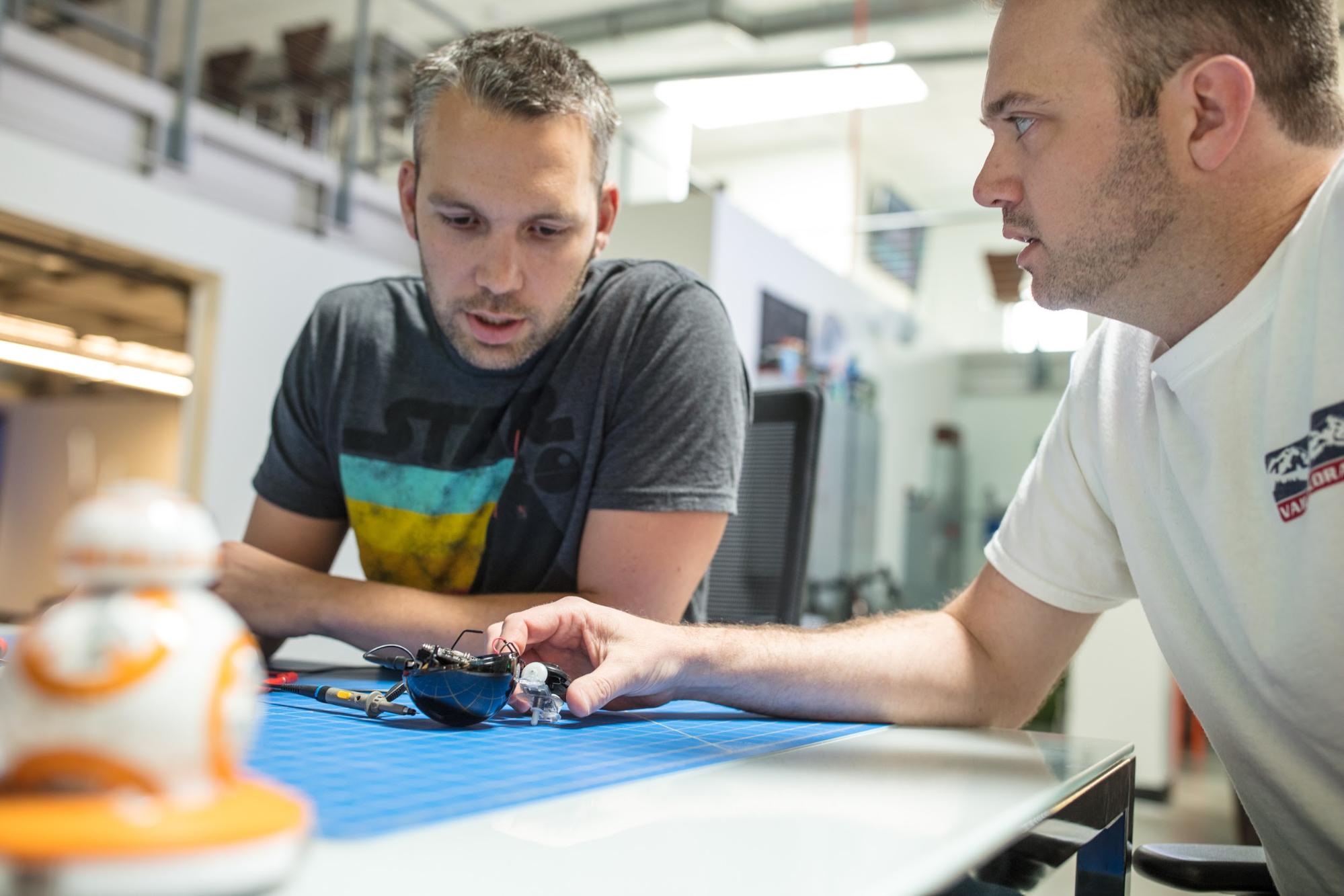

We teamed up with Sphero’s engineers for Force Friday to take a closer look at BB-9E and R2-D2 in two exclusive teardowns. After the teardowns, we talked with three of Sphero’s engineers about their experiences partnering with Disney to develop BB-8, BB-9E, and R2-D2.

In this exclusive interview, Senior Electrical Engineer Richard Rhodes and Senior Mechanical Engineers Judd Nutting and Gus Aramayo share their thoughts with us about what it’s like to collaborate on products with Disney, their inspirations when developing droids for denizens of Earth, and their engineering process.

Replicating a Disney Character Without CAD

Like many Star Wars fans, Lucasfilm has exacting criteria for character development—the physical product must stay true to the original artwork. For the development of the new BB-9E toy, Disney shared a variety of images and movie props with the Sphero team, but not CAD files, so Sphero’s engineers were tasked with the incredibly challenging problem of constructing the new product’s shape and dimensions from scratch.

“BB-9E’s head is a trapezoid shape, and for the first few prototypes, the shape was off by about ten degrees and looked a bit odd… we spent a lot of time iterating on the shape to make sure it was true to the original design,” shares Judd.

So how did the team know when they hit the mark? Lots of back-and-forth with Lucasfilm for approval.

“We would send them our design iterations and each time they might say, ‘This color’s a little off,’ or “This line needs to move this way,” adds Judd. “On BB-9E’s face, blue lights were measured down to a tenth of a millimeter, and we fought to get it as close to perfect as we could. When you scale down, a lot of the details get really tiny and you need to consider if you can even manufacture a 0.05 mm difference easily.”

Developing a New Inductive Charging Technology

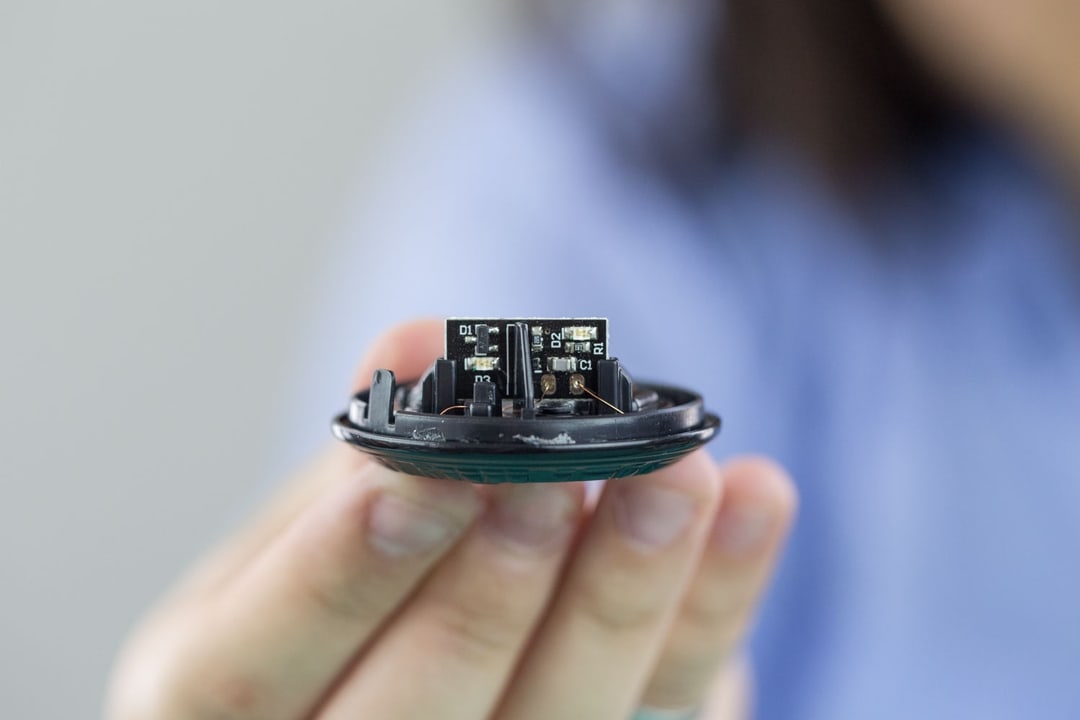

The biggest innovation in the new BB-9E Sphero droid over the original BB-8, is the introduction of inductive charging technology for the lights in the head.

Richard, who led the development of this technology, explains his inspiration to place inductive coils in BB-9E’s head:

“When I first began working at Sphero, we were exploring a different iteration of BB-8 with an in-house inductive charging solution. That project never came to fruition, but I had done all this research on a unique inductive charger,” Richard recounts. When Sphero began to work on BB-9E, it was a great opportunity to revisit this proprietary inductive charging solution. “I started playing around with it, and I had always wanted to make his eye an LED since it looks like one, so I thought I could put power in his head.”

Being a team full of creative and ambitious engineers, initial ideas for BB-9E’s technology included infrared, obstacle avoidance, and speakers in the head.

“Those didn’t work out since we were working against the immovable Force Friday deadline,” Richard notes, “but the lights did, since it’s a very lightweight and low-cost solution, and I proved it could be electrically efficient enough.”

In a Sea of R2 Replicas, Sphero Aimed to Create the Best

After selling over a million BB-8s, Sphero turned their attention to R2-D2, a cross-generational droid who appeals to today’s kids and their parents, grandparents and even great-grandparents. After researching other R2-D2s on the market, the Sphero team pitched Disney on allowing them to build a new R2-D2 toy, which would be in relative scale to Sphero’s BB-8. When Disney gave them the OK, the project kicked off in late 2016, to get it to market by Force Friday.

After conducting extensive research on how to build an R2 character in a small form factor, they 3D printed a rough prototype.

“We printed it straight up blue on an FDM printer, so we essentially had a blue can driving around the office,” laughs Judd. “We tried to stay really true to all the details—the power coupler, the grill, the power ‘hoses’ on his feet—we packed a ton of hardware into R2-D2.”

“We wanted a really well decorated R2 that was authentically designed, with all the little details,” adds Judd.

As the company’s first bipedal robot, R2 presented specific development challenges.

“It came down to the bipod-to-tripod transformation and the waddling,” notes Gus, who led mechanical development for R2-D2. “One of the biggest challenges was the mid-leg deployment—we learned people wanted to see it come all the way down, like in the movies.”

To aid in their development, they consulted an expert from the R2-D2 Builders Club to explore how they could ensure that R2’s foot wouldn’t get stuck on carpet, and what a collector would want to see in this new product. Then, the engineers examined the ankle joints and concluded that if they could isolate that motion, they’d be able to animate the waddling motion realistically in their robot.

Controlling four different degrees of movement could involve a lot of motors, but they were able to make it happen with just one.

“It all runs off of one motor connected to individual CAMS,” explains Gus. “On one end, we are in tripod mode, and each of those CAMs goes through his different positions. It was quite the challenge, with just one motor.”

The engineers needed to get a small motor into the robot’s foot that was powerful enough to drive him along the ground, and they also needed to find real estate for a small motor and a gearbox. The ankle box on each foot actually has gears on it, then runs back out to the belt drive, using every available millimeter.

“We have a partner we worked with to source the high-power motors, so we worked with them on the frame size, derived exactly what we needed for torque at a given speed, and then out of that we sourced a custom winding for the motor at that speed,” explains Judd. “We used common motors with a normal package size, but tuned them to our exact parameters and optimized with the custom windings.”

Exploration Without Limits

When it comes to creating life-like features for toys, the Sphero mindset is to start the exploration process without constraints.

“When a ridiculous challenge is posed, none of us here go, ‘That’s not going to happen,’” says Richard. “Our default position is, ‘how can we do that?’ We start collaborating on ridiculous ideas, and then we sometimes find out they’re not as ridiculous as we thought! That’s the magic of our team and the beautiful thing about working here.”

So what’s next for Sphero?

“We really enjoy working on characters and want to make products that are memorable and character driven,” says Judd. “The next things we make will continue to embrace what we’ve learned around how to make a character that’s fun and endearing.”

Check out Sphero’s store to get your hands on they new BB-9E and R2-D2 toys. For more exclusive interviews with the engineers behind the best hardware teams, be sure to subscribe below!