Time to read: 7 min

Robots seem to be everywhere these days – working in movies, airports, food production, and even in factories making other robots. Robots have many different functions and uses, and as they become easier and cheaper to make, they become more pervasive in industry as well. As the demand for robotics technology increases, bot makers need to keep up, and one essential method for manufacturing robotics components is CNC machining. Read on to learn more about the standard parts of a robot, suitable robotics materials and why CNC machining is so critical to robot manufacturing.

CNC Machining is Tailor Made for Robotics

For one, CNC machining is capable of producing parts with extremely quick lead times. Almost as soon as you have the 3D model ready, you can begin making components with a CNC machine. This allows rapid iteration for prototypes and quick delivery of custom robot parts for specialty applications.

Another advantage of CNC machining is its ability to create parts exactly to spec. This manufacturing precision is particularly important for robotics, where dimensional accuracy is key to building high-performing robots. Precision CNC machining can hold tolerances as tight as +/- 0.0002 in., and such rigorously crafted parts allow for the precise and repeatable movements that robots are known and valued for.

Surface finish is another reason to use CNC machining to produce robotics components. Interacting parts need to have low friction, and precision CNC machining can produce parts with a surface roughness of as low as Ra 0.8 μm, or even lower with post-processing operations like polishing. In comparison, die-casting (before any finishing processes) generally produces a surface roughness of closer to 5 μm. Metal 3D printing produces an even rougher surface finish.

Finally, the types of materials that are used in robotics are good candidates for CNC machining. Robots need to be capable of steady movement and lifting objects, requiring strong, stiff materials. These necessary properties are best achieved by machining certain metals and plastics, as outlined in the materials section below. Additionally, robots are often made for custom purposes or in low volumes, which makes CNC machining a natural choice for robot components.

Types of Robot Parts Made with CNC Machining

With so many possible functions, many different types of robots have evolved. There are a few main types of robots that are commonly used. Articulated robots have the single arm with multiple joints that many have seen. There are also SCARA (Selective Compliance Articulated Robot Arm) robots, which can move things between two parallel planes. SCARAs have high vertical rigidity, because their motion is horizontal. Delta robots have joints positioned at the base, which keeps the arm lightweight and able to move quickly. Finally, gantry or cartesian robots have linear actuators that move at 90 degrees to one another. Each of these robots are constructed differently and have different applications, but there are five main components that commonly make up robots.

- Robot Arm

- End Effectors

- Motors

- Controllers

- Sensors

Robot Arm

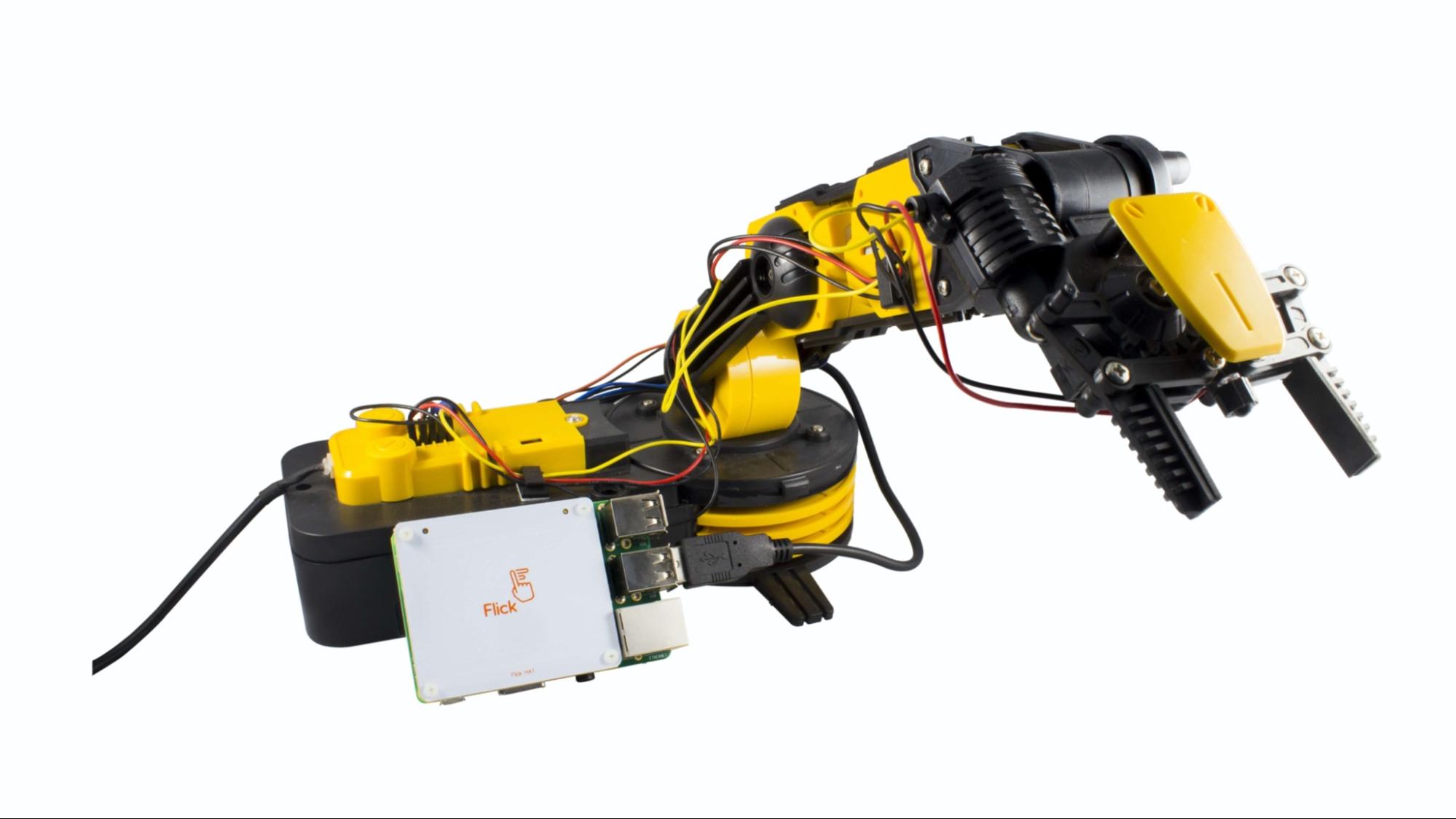

Robot arms vary greatly in both form and function, so it follows that a lot of different components can be used. However, one thing they have in common is that they are able to move objects or perform an operation on an object — not unlike a human arm! And different parts of a robot arm are even named after our own: shoulder, elbow, and wrist joints rotate and control the movements of the segments in between.

The structural components of robot arms need to be stiff and strong, so that they can lift objects or apply a force. Because of the materials that are used to satisfy these requirements (steel, aluminum, and certain plastics), CNC machining is the right choice. Smaller components, such as gears or bearings in the joints, or parts of the enclosure that surrounds the arm, can also be CNC machined.

End Effectors

An end effector is an attachment that you connect to the end of a robot arm. End effectors allow you to customize the robot’s function to different operations without building a whole new robot. They can be grippers, grabbers, vacuums, or suction cups. These end effectors generally have components that are CNC machined out of metal, often aluminum (more on material choice later). One of these components attaches permanently to the end of the robot arm. The actual gripper, suction cup, or other end effector (or array of end effectors) mates with this component, so it can be controlled by the robot arm. This setup with two different components allows different end effectors to be changed out more easily, so the robot is adaptable to different applications. You can see this in the below image. The bottom disc would bolt to the mating component on the robot arm, allowing you to attach the hoses that operate the suction cups to the robot’s air feed. The top and bottom disc are examples of CNC machined parts.

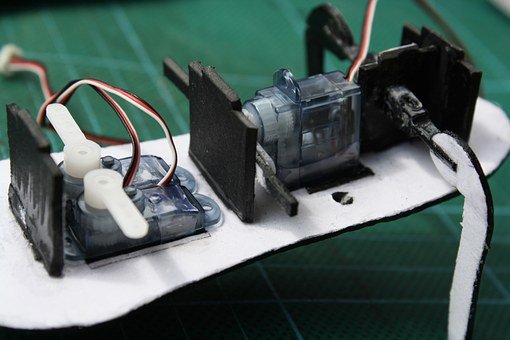

Motors

Every robot needs motors to drive the movement of the arm and joints. A motor has many moving parts in itself, and many of these parts can be CNC machined. Generally, a motor has some kind of machined enclosure for the power source, as well as a machined bracket to attach it to the robot arm. Bearings and shafts are also often CNC machined. Shafts can be machined either on a lathe to turn down the diameter, or on a mill, to add features such as keys or slots. Finally, the gears to transfer the motion of the motor to the joint or other part of the robot can be CNC machined by milling, EDM, or gear hobbing.

Controllers

The controller is basically the robot’s brain, and does what you think it does — it controls the often precise movements of the robot. As the computer of the robot, it takes input from the sensors (see below) and modifies the program that controls the output. This requires a printed circuit board (PCB) to house electronic components. This PCB can be CNC machined to the size and shape necessary before adding the electronics.

Sensors

As mentioned above, sensors take in information about the robot’s surroundings and feed it back to the robot’s controller. Sensors also require PCBs, which can be CNC machined. Sometimes these sensors are housed in a CNC machined enclosure as well.

Custom Jigs and Fixtures

Although not a part of the robot itself, custom jigs and fixtures are necessary for most robot operations. You may need a fixture to hold a part in place while a robot works on it. You can also use a fixture to precisely locate a part each time, which is often necessary for a robot to either pick up the part or set it down. Because they are often one-off, custom parts, CNC machining is perfect for fixtures. The lead time is short and the CNC machining is usually done easily on a piece of stock material, often aluminum.

Preferred Materials for Machining Robot Parts

For robotics, material consideration is critical. Parts need to be strong, tough, and robust, able to withstand impacts, lift or support objects, and perform repetitive tasks. They also need to be lightweight enough to be manipulated by the motor, and there are certain materials that are suited particularly well to these requirements.

Aluminum

Aluminum is a great choice for machining robotics components. This metal is easy to machine and has a high strength to weight ratio. Aluminum is also corrosion resistant, allowing it to withstand a range of environments. It’s appropriate for small to medium sized robots, because larger robots that do heavy lifting require even stronger materials.

Steel

Steel is denser than aluminum, but it is strong and hardy, making it a good choice for larger, heavy duty robots. It has high impact resistance and high stiffness, again making it a good choice for heavy lifting operations. And alloy steel 4340 is a great choice, because it has particularly high hardness and strength, with a yield strength of 72 kpsi.

Polyoxymethylene (POM)

POM, also known as delrin or acetal, is a polymer that is easy to machine. It has a low coefficient of friction, which makes it well-suited for gears and bushings. It also has high stiffness and good dimensional stability, which are both critical properties when building bots with precise movements.

Acrylonitrile Butadiene Styrene (ABS)

ABS is another plastic that is machinable; it can even be threaded. It’s rigid and strong, with a yield strength of around 5000 psi. It’s less dense than aluminum and steel, and is also impact resistant. These properties make it a good choice for components on smaller robots that perform repetitive tasks.

Conclusion

Hopefully you can now see why CNC machining is such an integral part of your robotics production process. A wide range of materials can be CNC machined to extremely tight tolerances to ensure your robot will be able to execute the precise movements you need it to. And with the CNC process, you’ll get your parts quickly, which is critical for both custom one-off and larger scale builds.

Learn more about how HEBI Robotics and Gecko Robotics used China Manufacturing parts, Inc. to bring their cutting edge robot designs to life. Want to start your own robotics CNC machining project with us? Sign up for a free China Manufacturing parts, Inc. account today!