All articles from the author

Article

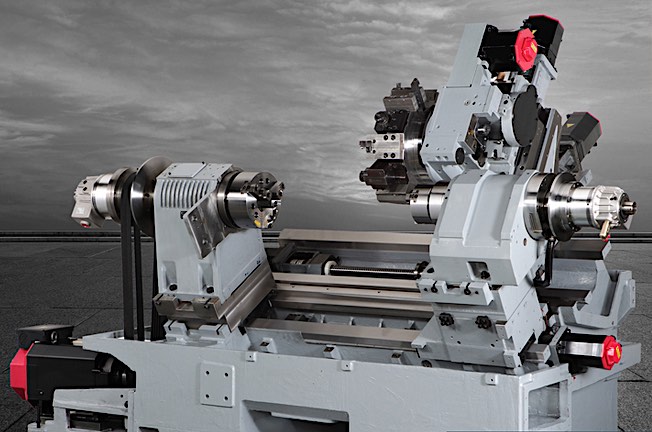

Introduction to CNC Turning

Previously, we discussed how CNC (Computer Numerical Control) supports manufacturing processes and reduces human error. We have also described CNC Milling, where the cutting tool moves while the workpiece is fixed in place. In this article, we‘ll explore CNC Turning, where the workpiece rotates while the cutting tool remains stationary. CNC Lathes vs. CNC Turning Centers […]

Article

Introduction to CNC Milling Cuts and Toolpaths

This article is a companion to Getting Started with CNC, an introduction to the different types of CNC milling machines and the software used to design the parts they produce. Here, we’re going to discuss CNC milling terminology, toolpaths, and common operations. Chip Formation You may have seen images like Figure 1, which show how […]

Article

Getting Started with CNC Milling

Computer numerical control, or CNC, is one of the most common and well-known automated processes in manufacturing. CNC machines help companies and individuals make manufacturing processes easier to inspect and control while reducing human errors. They’re used for milling, turning, plasma cutting, electrical discharge machining, water jet cutting, punching, drilling, laser cutting, and more. This […]

Article

The Basics of Electrical Discharge Machining (EDM)

Sometimes when you’re choosing what manufacturing method to use, the requirements for dimensions, materials, and specifications make conventional production processes too expensive. Milling, turning and drilling to machine a block with openings and chamfers that will hold bearings or other components is complex and difficult. Of course, you can cast parts, but the up-front cast […]

Article

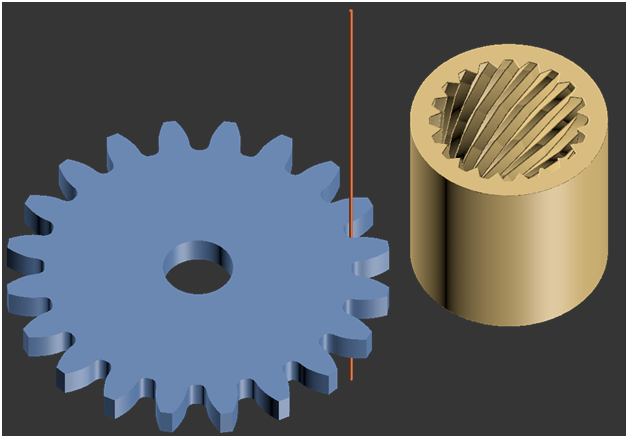

The 3 Essential Methods for Gear Machining

Historically, gear fabrication methods fall into three main categories: generation, forming, and form cutting. As new technologies are developed, there may be new gear machining methods added to the list, but the big three are still the most common ways to make a gear: Gear generation methods use cutting tools in the shape of the […]

Article

EDM: Sparks Fly with This Gear Manufacturing Process

Gears can be fabricated using a myriad of different manufacturing methods. As you may expect, the profile of the teeth needs to follow specific dimensions and constraints in order to transmit torque, prevent slippage and excessive undesired contact stresses. Therefore, the fabrication process you select should accomplish the necessary tolerances and properties. This article will […]

Article

The Ultimate Guide to Finishing CNC Machined Parts

Welcome to part II of our three-part series about secondary operations. This article covers finishing options, while the others discuss heat treatments and hardware installation. When discussing CNC machining surface finishing options, you may have heard terms like as-machined, anodizing, powder coating, or media blasting. But before we dig into the details of those processes, […]

Article

What is ISO 2768? A Guide to Tolerance Standards for CNC Machining

Fabricating a product without deviations from the original design is extremely complicated. Even if you’re able to get an instance comparable to your design intention, it’s nearly impossible to achieve the same exact dimensions in a batch process. That said, you can decide how much a fabricated product can deviate from the original intention in […]

Article

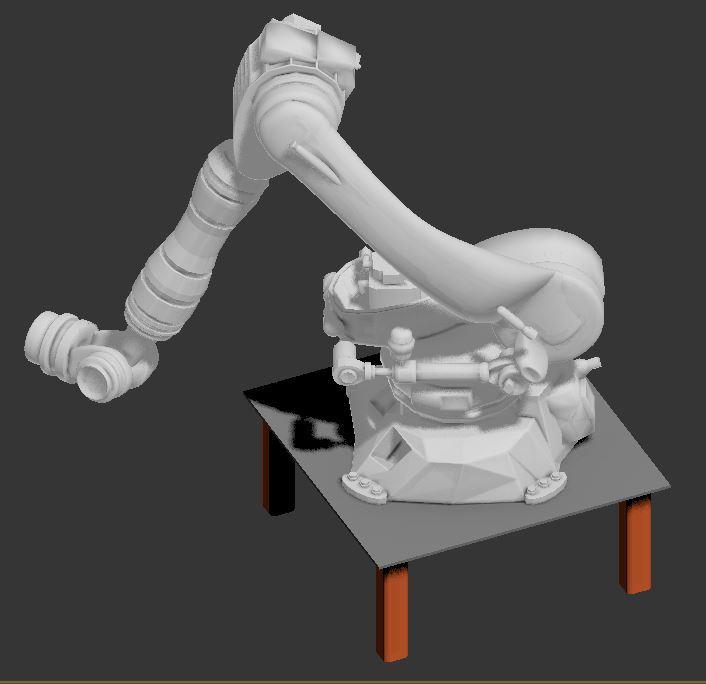

3D Modeling: From Fundamentals to Advanced Techniques

The computer modeling world is a vast array of techniques and programs that can serve as tools in aiding professionals to create, simulate, and visualize their designs. This article will introduce some different types of 3D modeling software and then walk through a sample workflow in Solidworks to show you what you can do with […]