We love selfies at China Manufacturing parts. We even have human selfie sticks, also known as founders, but really we keep them around for their 6-foot-plus wingspan. However, as of late, our team has grown so much that we can’t all fit into a standard phone selfie. This is the worst kind of growing pain! Our culture is under threat!

However, we recently discovered a gadget that holds great promise for solving our crisis. It can take panoramic images with just one click and then wirelessly send the photos to a mobile device, so we can post them on Twitter, Instagram, Facebook, SnapChat, and social networks you’ve never even heard of.

I present…the Ricoh Theta S, savior of our corporate identity.

The Theta S and its little sister, Theta m15, have two fisheye lenses. With one lens on each side of the camera, no one is left out of the selfie, as long as they can see a lens. To learn more about the camera’s functionality, check out some images from Theta’s official gallery and read this well-informed review. In this post, we’ll focus on how the Theta S is built.

The camera’s front and back enclosures are plastic with soft-touch paint. Soft-touch paint feels good, but it’s a huge fingerprint magnet and scratches easily. The convex lenses could easily get damaged, too, since they stick out of the body so much. There’s no lens cap, but the Theta S does come with a fitted neoprene pouch for some protection.

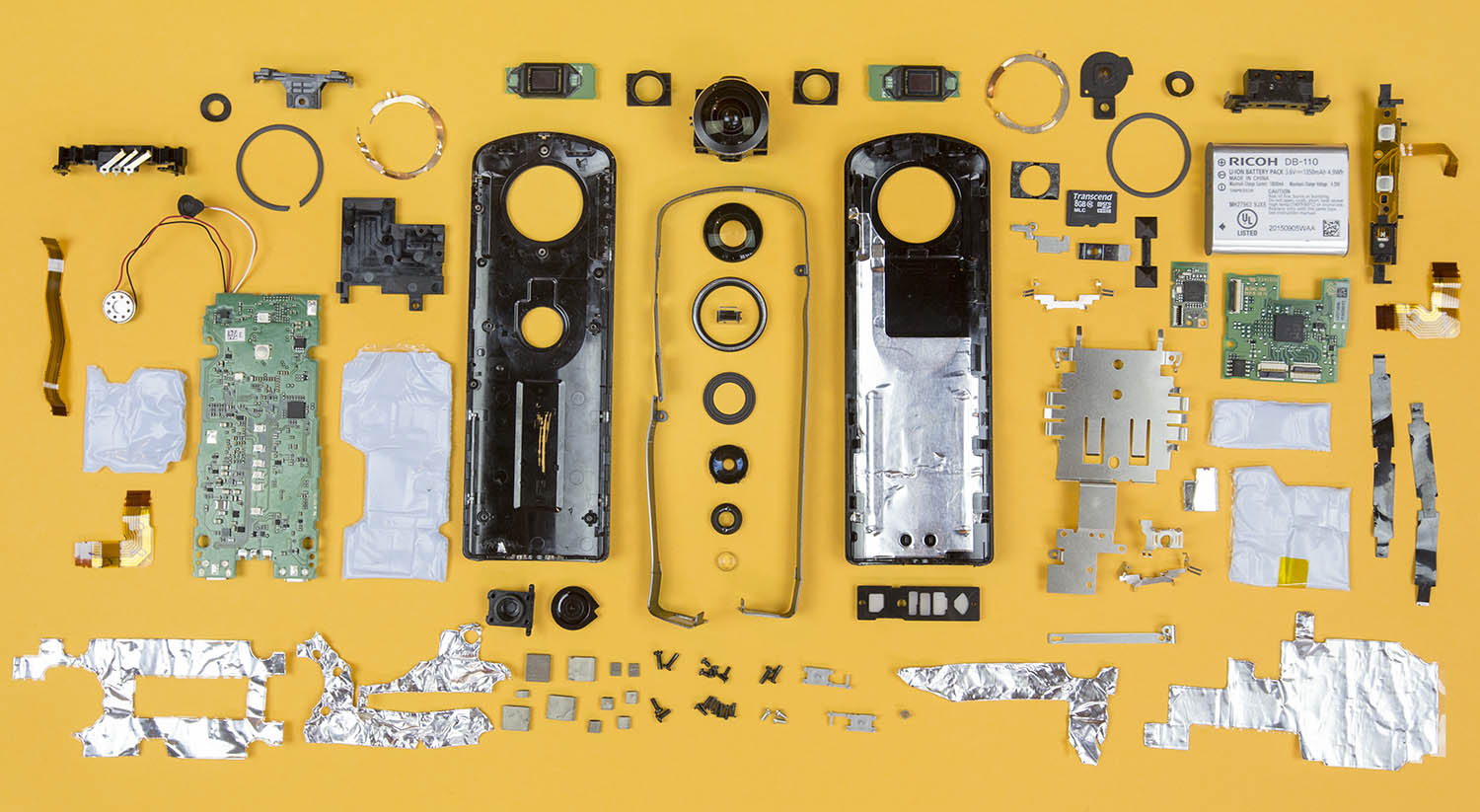

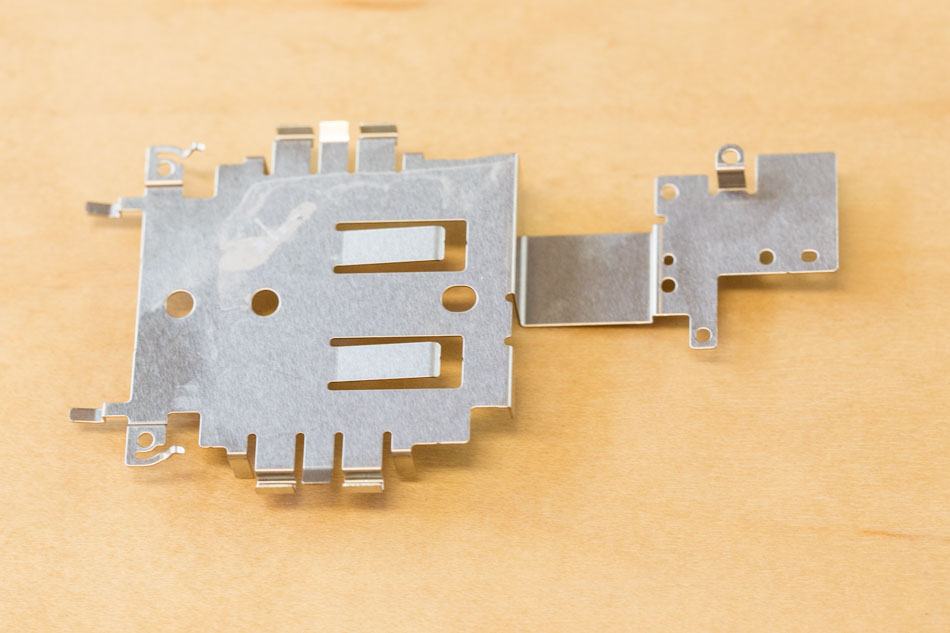

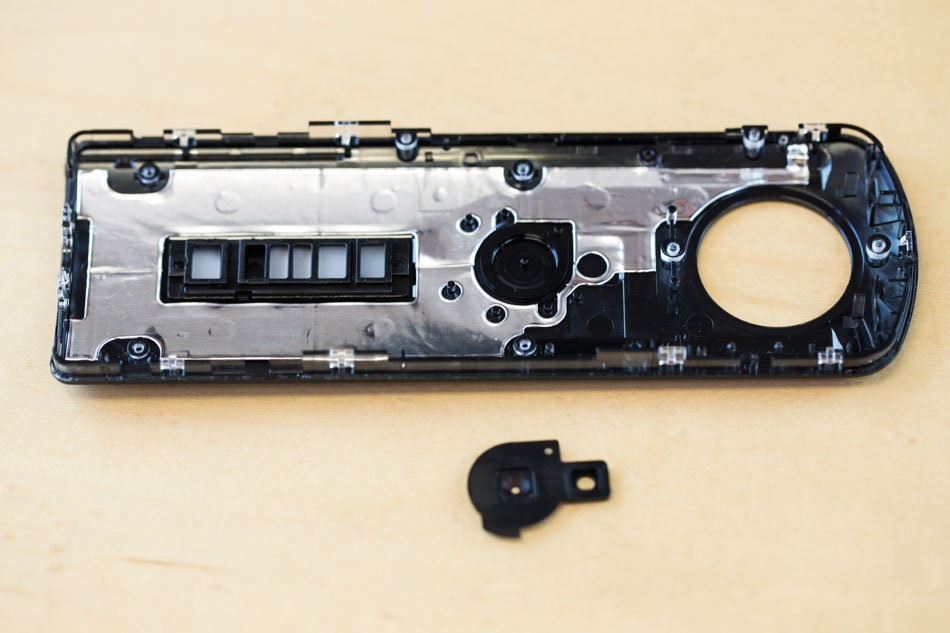

There are no visible screws on the outside of the device; an aluminum sheet metal trim wraps all the way around the body. We peel this trim back to reveal how the two halves are actually held together: by eight snap fits.

We’re actually able to take a few screw tabs off the aluminum trim by forcefully peeling the trim off the body. During assembly, the aluminum trip would be fastened to one enclosure half by screws, and then the other enclosure half snaps on. There’s no clean way to reverse this process: If you want to repair Theta S, it won’t be easy.

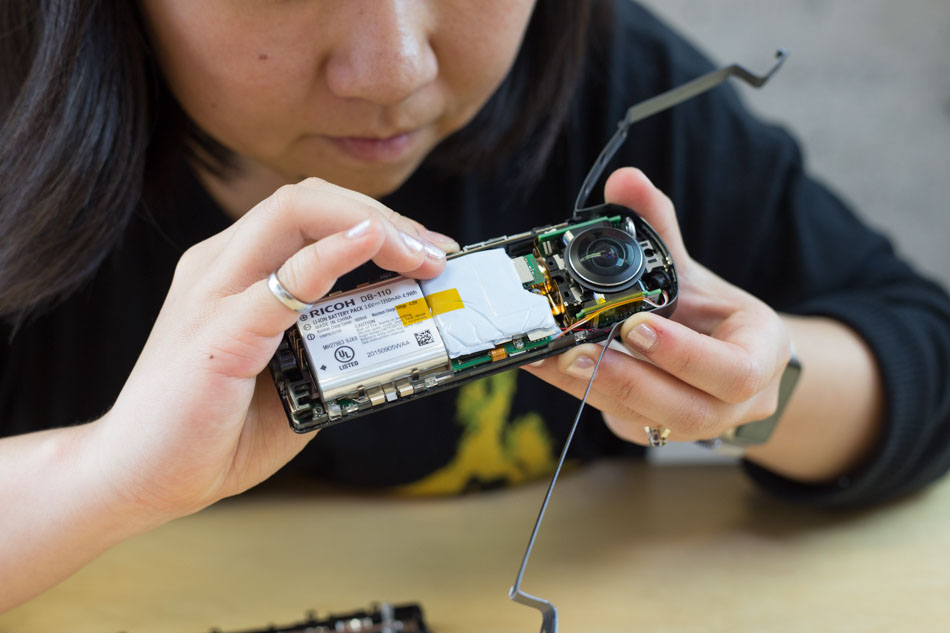

After we get the “front” cover off, we find a 1350mAh Lithium-Ion battery and a thermal pad that’s almost as large in area.

We’re surprised by the battery’s form factor: It’s a removeable type, but it’s not intended to be user-removable. Perhaps this battery is being used in another Ricoh product that allows battery swaps, so it made sense to reuse an existing component.

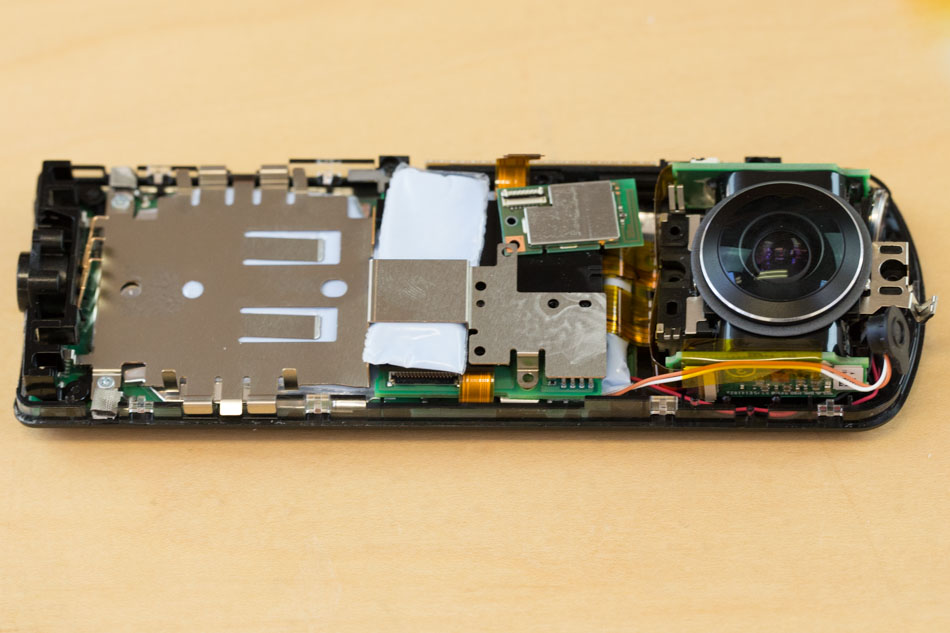

After removing the battery and thermal pad, we find a large sheet metal bracket standing in our way.

The cnc aluminum bracket is fastened to the enclosure via small screws. It has quite a few spring features to hold down other components, like more thermal pads!

There are four thermal pads in total. These PCBAs must get really hot for such serious thermal management.

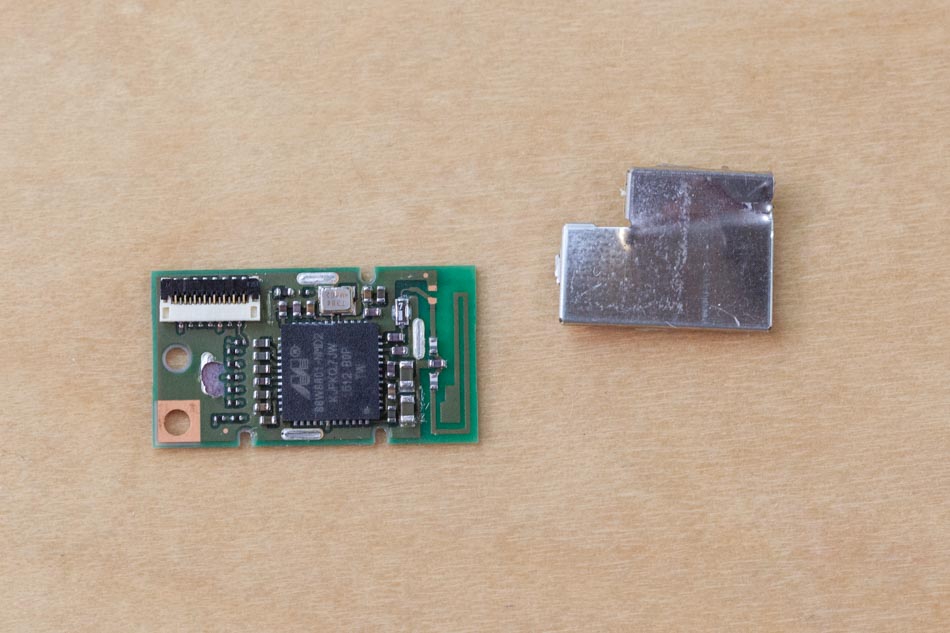

Despite the small form factor of the camera, Ricoh engineers somehow managed to cram five rigid PCBAs inside. This is the WiFi board, featuring a Marvell 88W8801 WiFi system-on-a-chip under a shield.

This board holds an Xylinx Spartan-6 XC6SLX9 FPGA. It must be a part of the custom image processing engine.

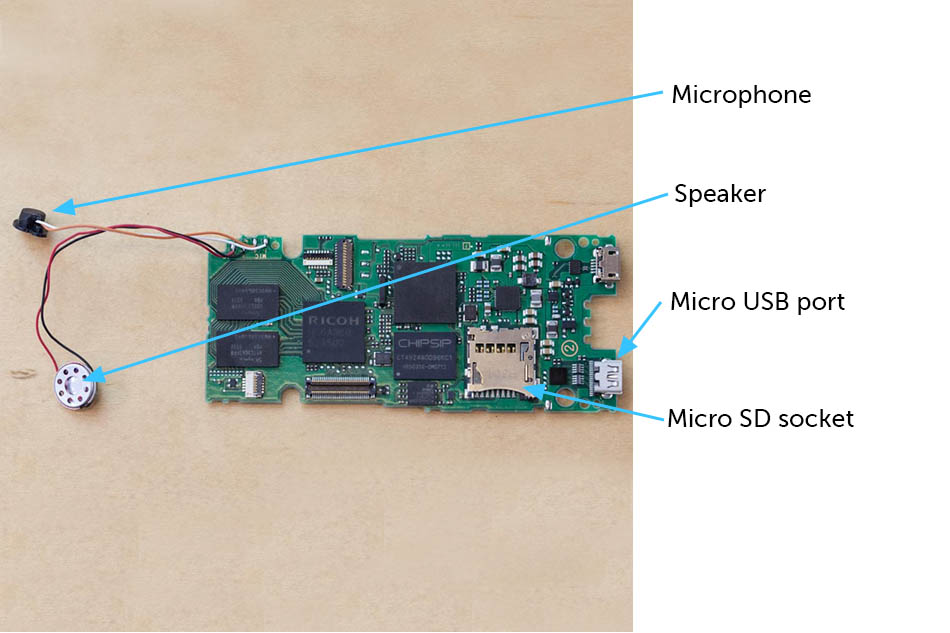

Here, we have the main PCBA, crowded with ICs. Here are some that we identified:

- Fujitsu MB91696AM image processor, which has a dual-ARM core and built-in H.264 codec that supports full HD video

- ChipSiP Memory chip

- SK hynix RAM

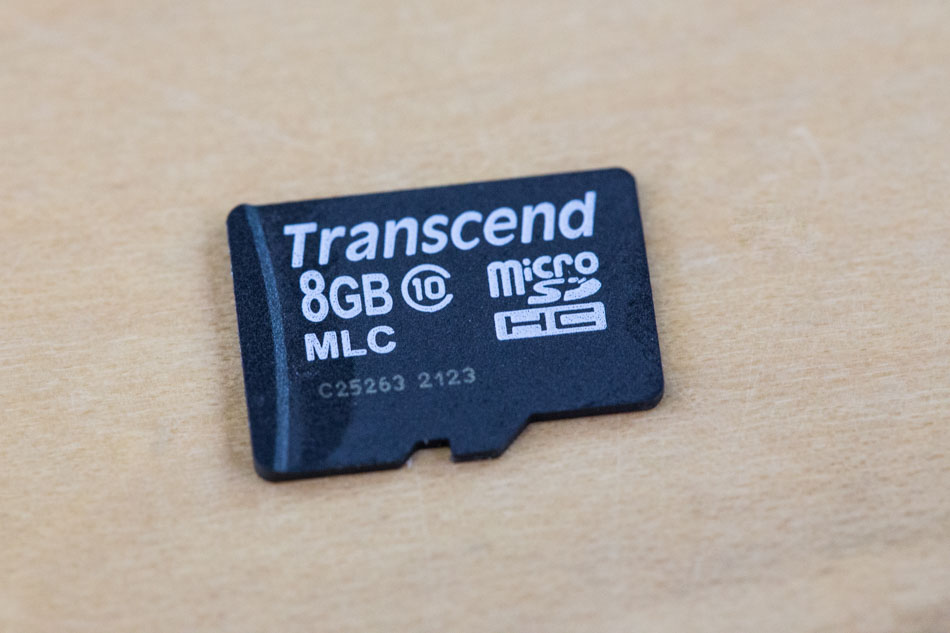

It’s interesting that there is a microSD socket on the board. There is an 8GB microSD card inside! Again, this is the kind of component one would find in a device that allows expandable memory, but the Theta S does not. However, this allows Ricoh to sell a separate SKU of Theta S with, say, 16GB memory, with zero engineering cost.

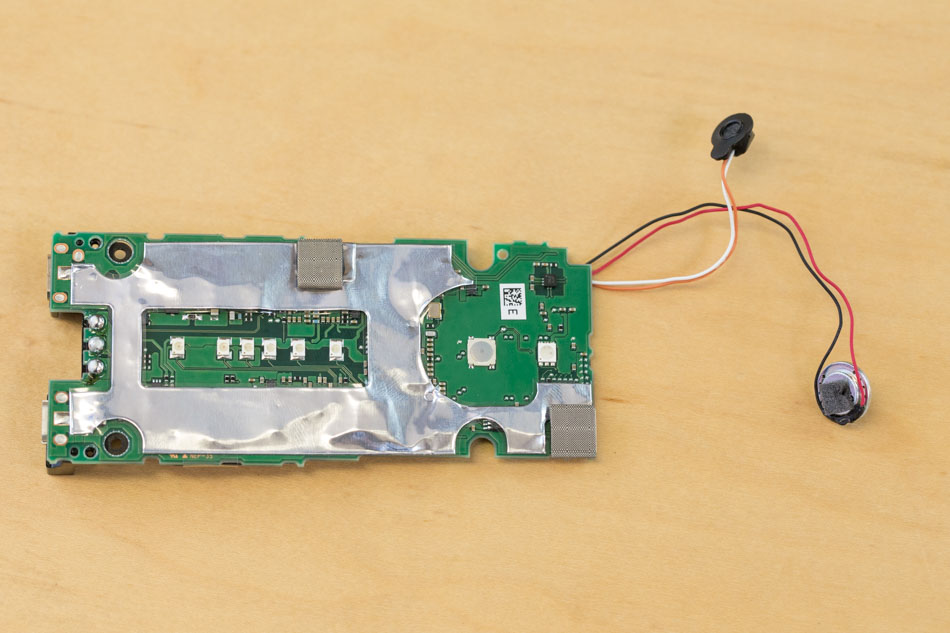

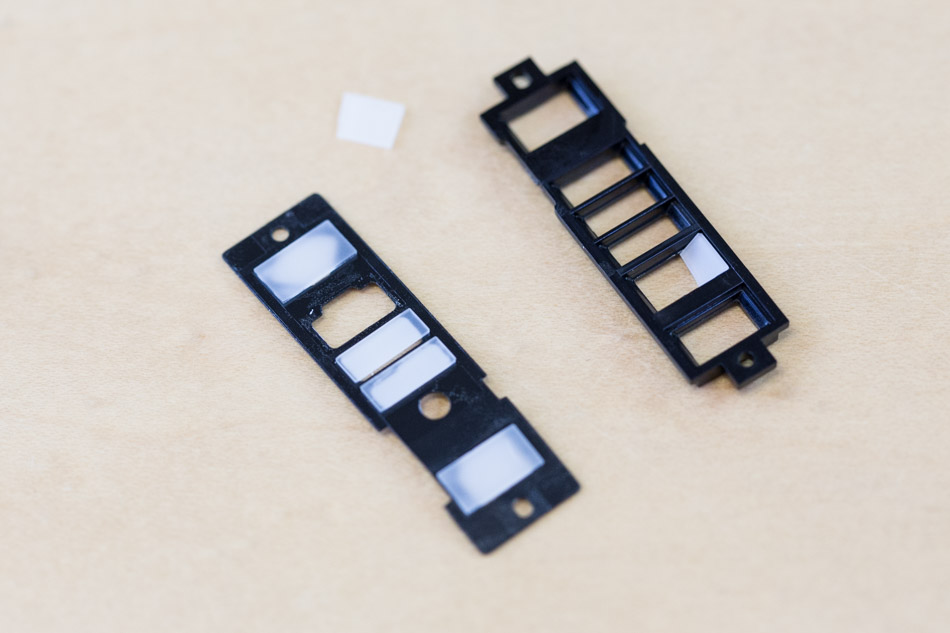

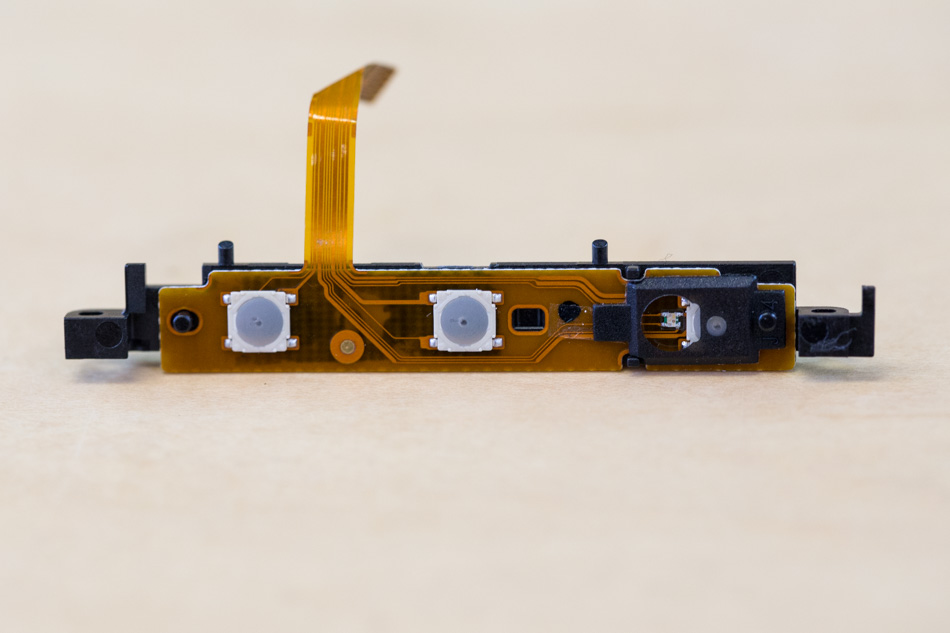

The back of the main PCBA has quite a few LEDs for status indication and a low-profile dome switch that works as the shutter.

The LEDs nest neatly into a shroud that prevents the indicator lights from bleeding into each other.

The enclosure holds a secret: The indicator lights are only visible when they’re on. The shutter-side enclosure is clear polycarbonate, but it’s painted with a masking layer and then a soft-touch layer. When we hold the enclosure up to a light, you can see all the masked shapes. This is called dead-fronting. You can also achieve this effect with in-mould labeling (IML).

In contrast, the other side of the enclosure doesn’t have any lights, so it’s just black plastic painted with soft-touch.

Buttons & Switches

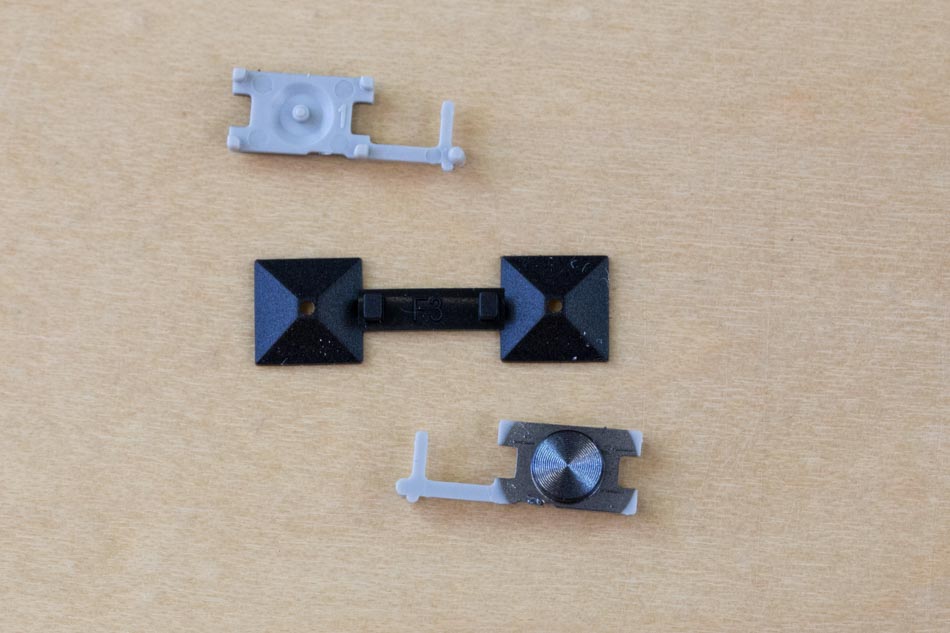

There are four pushbuttons on the Theta S.

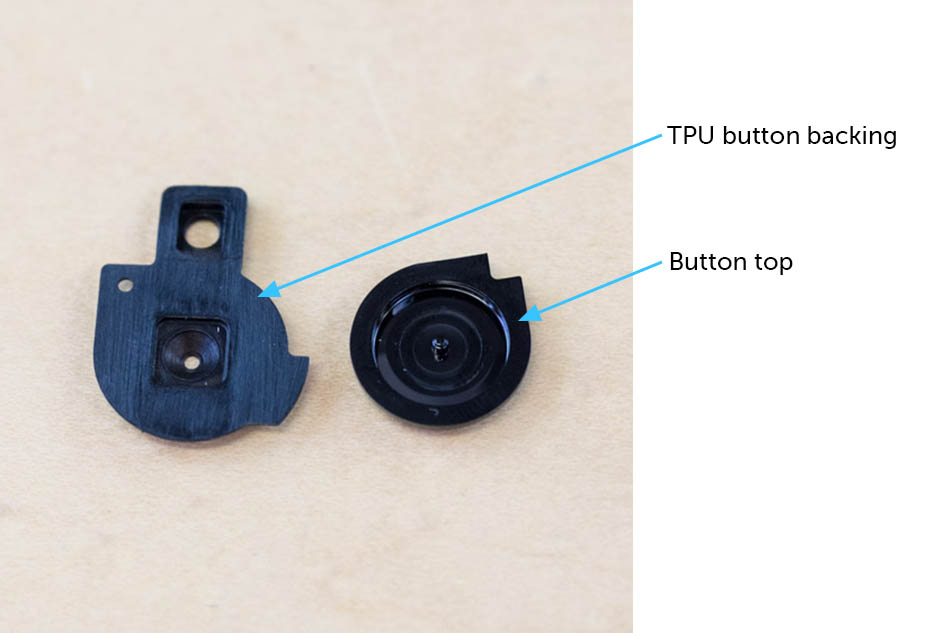

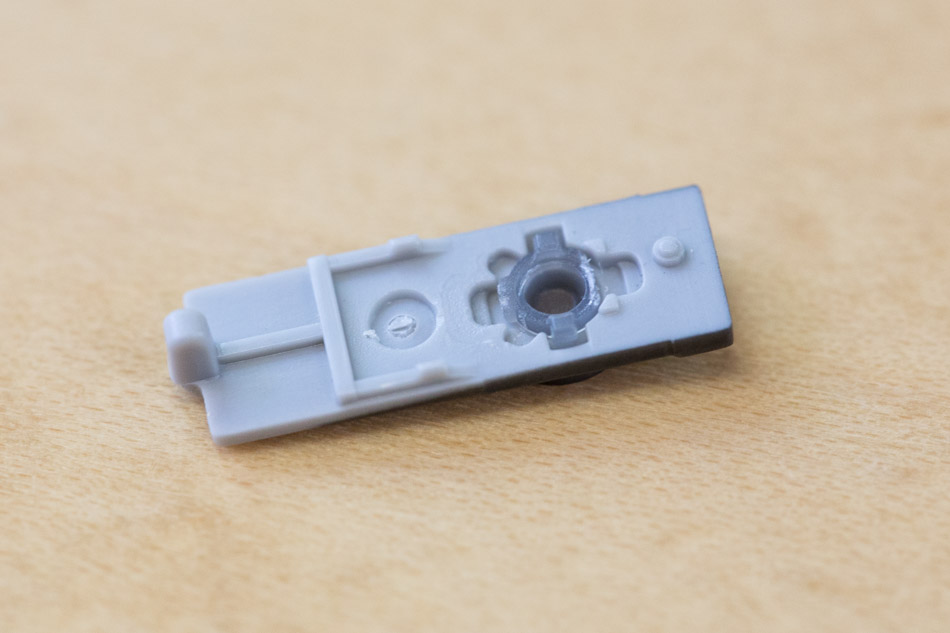

The shutter button top is of rigid plastic, painted to match the soft-touch enclosures. Between the metal dome switch and the button, there is a thin TPU gasket to soften the button feel.

The other three buttons are on the side of the camera and have the same dome switches as the shutter. The power switch has a neighboring LED to light it up.

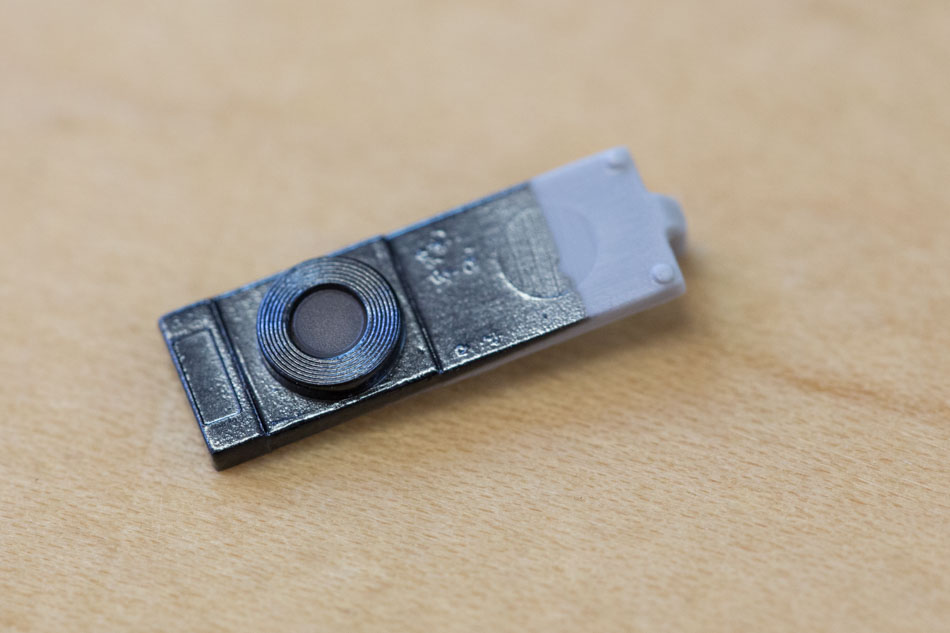

The button tops are very convincingly painted to match the aluminum trim. They’re even knurled to look more metal-like. Similar to the shutter button, there are TPU gaskets between the button tops and the switches.

The power button is a two-piece design to allow light to shine through.

Optical Train Assembly

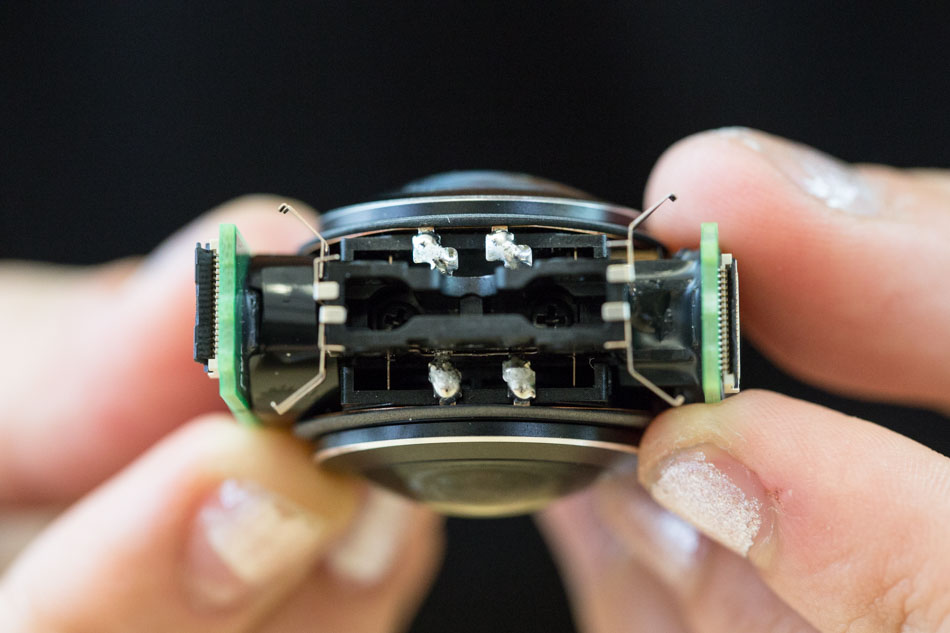

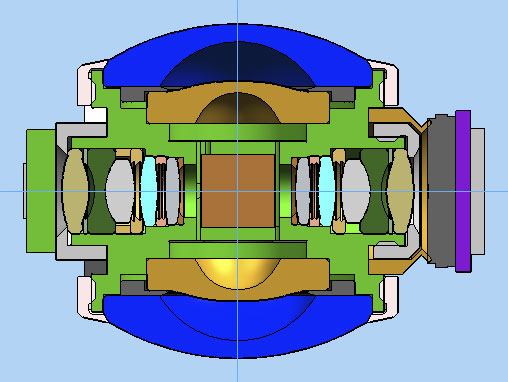

The most unique and interesting part of this camera is no doubt the optics, where two fisheye lenses are stacked back to back to take 360 degree photos and video.

In conventional cameras, the imaging sensor (CMOS, or less commonly, CCD) is mounted directly behind the lens. To minimize the camera’s thickness, Ricoh’s ingenious optical engineers moved the CMOS sensors onto the side of the optical train.

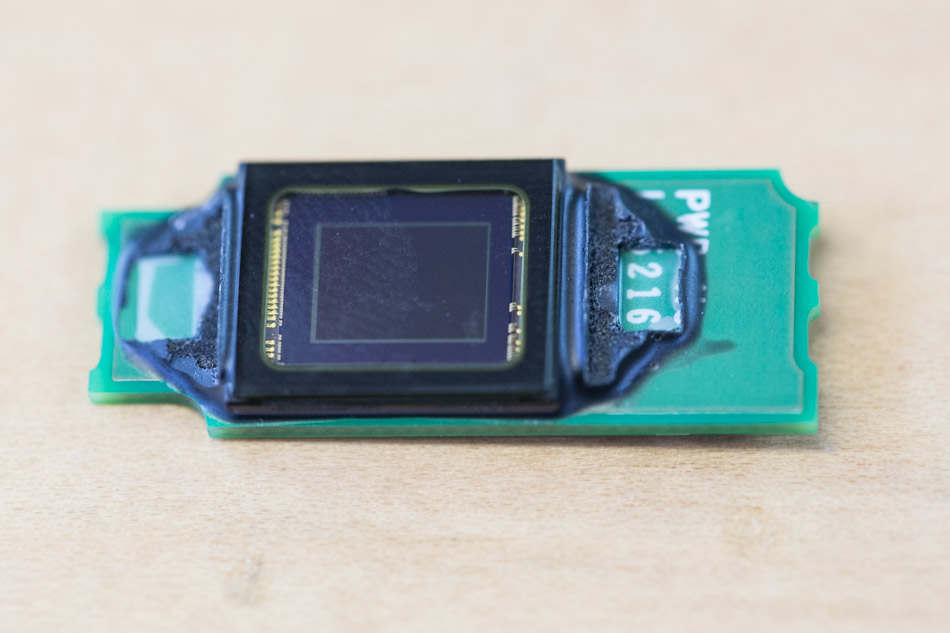

We remove the imaging sensor PCBAs to get deeper into the optical train. There is a twelve-megapixel, 1/2.3” CMOS sensor on the imaging PCBA.

With the imaging PCBA removed, you can see another lens orthogonal to the fisheye lens. This small lens focuses light onto the CMOS sensor.

How is the image “seen” by the fisheye lens? There are two prisms in the center of the optical assembly that “bend” the direction of light.

Each side of the assembly features seven elements in six groups. If this sounds like a lot, it’s actually not: The iPhone 6S has a five-element lens, and a 3x optical zoom lens can have ten elements.

Main Takeaways

The Ricoh Theta S is such a unique camera! The optical train blew us away: It’s unlike anything we’ve seen before.

The product has really high build quality, although some features felt excessive, such as the lit-up power button. The cheaper Theta m15 seems to do away with the dead-front indicator lights and concentric button lighting.

There are so many parts in this camera: lots of little sheet metal brackets, EMI shielding gaskets, and screws. It’s got almost enough aluminum foil to wrap a Mission burrito. Oh, and don’t forget the thermal pads!

The optical train alone probably takes longer to assemble than some complete products. While our manufacturing mantra is to ruthlessly eliminate components, we can appreciate how much engineering and attention to detail went into this product.