Time to read: 5 min

Designing components with snap fits can save you time and money in production by reducing material costs and part quantities as well as improving ease of assembly.

While in the past injection molding has been the only viable method for producing snap fit joints in plastics, 3D printing opens up new opportunities and challenges in their design.

And there are most certainly challenges! To help you navigate the complex world of snap fits we’re going to take a look at the key features, calculations and tips to overcome common issues for designing and prototyping these features.

Designing Your Snap Fit Joint

Note: Metric units are used for all calculations

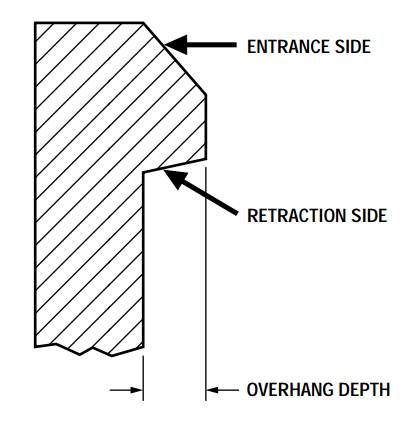

All joints have similar features and function. In its simplest form, a snap fit is a small protrusion (hook, bead, or bump) which is deflected during assembly to catch in a depression on the mating part. The shapes of the male and female parts then determine whether the joint can be separated and the force required to do so.

For the purpose of this article, we’re going to focus on the simple cantilever style joint. Entire books have been written (like here and here) about different snap joint design, but the cantilever style (and its variations) is both the easiest to design and the one you’re most likely to encounter.

As you can see in the diagrams above, the cantilever joint is modeled by a fixed-free beam with a point-applied end load.

The worst case stress and strain is found at the root of the cantilever and can be easily approximated using classical beam bending theory.

As the exact forces are not yet known when designing a model, it’s most common to use deflection and strain rather than force and stress values to set your dimensions. In other words, your dimensions will be limited by maximum strain during deflection rather than force required to assemble/disassemble (mating force).

Classical beam bending theory assumes the fixed end wall is rigid. However, the part walls are likely to be of similar thickness to the cantilever itself; Q is the deflection magnification factor added to account for this.

As the rigid wall is the worst case for strain in the root, for a simple casing, leave Q as 1.

Also note that the return angle affects the ease of joint separation. A return angle the same as the leading angle means the same force is used during assembly and disassembly. In contrast, a return angle of 90° can never be disassembled, except by using an external window to release the snap.

Implementing the Calculations

Now that we know which calculation values are needed when designing a cantilever joint, let’s look at how to find those values.

There are two ways you can approach these calculations:

- Material first: You have chosen your material, found its allowable strain and can design your dimensions to fit it.

- Dimensions first: Your primary dimensions are fixed and you can choose a material to fit.

Finding Acceptable Strain Limits

To find acceptable strain limits, use the yield stress and modulus of elasticity of the material with the following formula:

∈ = σ/E

where ∈ = modulus of elasticity [MPa], σ = stress [MPa] and E = strain [%]

So strain = stress / modulus of elasticity = change in length / initial length [%]

Pro Tip: 3D printed parts will have stress varying by axis, so for optimum strength, make sure the cantilever part of the joint is built along the X-Y plane and not traveling up the Z axis. If your cantilever can only be created in the Z axis, be aware elongation at break is reduced by 50% and tensile strength by 20-30%. We recommend reducing the allowable stress/strain by 50% for Z axis cantilevers. Ask China Manufacturing parts when uploading parts if you have questions here.

Here are the acceptable strain values for some common 3D printing materials:

| Material | Acceptable Strain |

|---|---|

| ABS-Like | 20-40% |

| VeroWhite | 10-25% |

| Transparent | 10-25% |

| ABS | 7% |

| PLA | 4-8% |

| Nylon | 4-15% |

And here are some calculated strain rates for different wall thicknesses, deflections, and cantilever lengths to help you get started.

Changing Your Cross Section

If you’ve calculated your dimensions, chosen your material, and the acceptable strain rate is still too high, the best solution is to change the cantilever cross section. The most common changes include tapering the width or thickness.

4 Common Problems + Solutions in Design Snap Fits

Here are some solutions to other common challenges engineers face when designing for snap fit components.

1. Creep/Stress Relaxation

Thermoplastics are particularly susceptible to creep – the gradual, permanent deformation of the material under stress. Over time this can compromise the connection between the male and female parts, or even render it useless.

Solution: Make sure your male and female parts are designed in such a way that while deflection may happen during assembly, during normal, assembled use the parts are not subject to prolonged bending or tensile stress.

2. Stress Concentrators

Sharp corners concentrate stress at the root of the cantilever, causing it to shear off.

Solution: Make sure there are no sharp corners to act as stress concentrators, especially on the tensile side of the cantilever. Use radi or chamfers to reduce this.

3. Fatigue or Repetitive Loading Failure

Repeated assembling and disassembling of snap joints can cause failure at stresses much lower than the rated stress of your material. Fatigue failure typically happens at high loading frequencies (hundreds if not thousands of cycles).

Solution: If you anticipate high cycle frequencies for your component, careful selection of a fatigue-resistant material using S-N curves is essential.

4. Tolerances

The tolerances are wrong and your parts won’t fit together.

Solution: Rule of thumb for gaps:

- 0.2 mm for tight fits

- 0.4mm for slide fits and pivot joints

- 0.3mm for a close fit snap joint

Main Takeaways

We’ve only scratched the surface here and if you want more in-depth information, check out some of the resources below.

Designing for snap fits is a complex and iterative process, but if you follow the simple engineering best practices covered in this article, you can improve the initial function of your snap fit joints and decrease your prototyping life cycles.

Further Reading

For a more in-depth analysis of snap fit design and to dive deeper into the material properties, check out these guides below.

Instant Quotes for 3D Printing & CNC Machining

Ready to upload your CAD models for physical prototypes? Get an instant quote for 3D printed parts in 24 hours & CNC machined parts in 3 days by uploading your files below.