Time to read: 9 min

The advent of CAD systems, additive manufacturing, and CNC machining has made the design and manufacture of complex part designs almost routine. Engineers today are being asked to design parts that will probably be exposed to many different factors, including extreme weather, chemicals, bodily fluids, high stress/high load, impact, and other elements and situations that could affect the way a product is designed. To achieve this sort of advanced product design in injection molding, advanced materials are often required.

In this guide, we’ll walk you through the manufacturing and industrial design considerations for a variety of material options and offer material recommendations for different product design objectives, including glass and fiber-filled materials for stronger parts and silicone and polyurethane materials for flexible parts.

How to Achieve Stronger Parts: Common Types of Fillers

Glass Fiber

The most common way to improve the mechanical properties of a plastic material is to add glass fibers. Glass fibers improve the structural properties like strength and stiffness and they reduce the shrinkage of the part. They are relatively inexpensive, can be added to most plastics, and glass-filled resins can be different colors.

In terms of drawbacks, glass fibers can make the part brittle and reduce impact strength. Glass fibers also decrease the life of the mold and wear on the barrel and nozzle of the molding machine. Glass filled resins will also raise the viscosity of the material, making the mold harder to fill.

Carbon Fiber

Carbon fiber fillers can improve the mechanical properties of a plastic material. Carbon-filled plastic parts have similar mechanical properties as glass-filled plastic, but result in stronger and lighter parts. Carbon fibers are conductive, so carbon-filled parts have better electromagnetic shielding properties. Even more than glass fibers, carbon fibers improve structural properties, like strength and stiffness, and reduce the shrinkage of the part.

The main drawback of carbon-filled parts is that they are expensive, and like glass fibers, carbon fibers will make the part brittle and reduce impact strength; decrease the life of the mold and cause wear on the barrel and nozzle of the molding machine. Carbon fibers will also raise the viscosity of the material, making the mold harder to fill. Keep in mind that for carbon-filled materials, the part color will be limited to black only. Some resins also need to have the mold temperature run very high, which could require expensive auxiliary equipment.

Tooling Design for Fiber Filled Parts

When glass or carbon fiber is compounded with resin, the plastic’s elasticity modulus and tensile strength will significantly improve, so the plastic part feels rigid. That means the plastic part won’t get deformed easily if a heavy load lands hard on the part.

However, the impact strength will be lower, and the plastic can feel brittle. The flowability will be lower, and the shrinkage in the flow direction will be smaller than the shrinkage perpendicular to the flow.

In tooling design, it’s hard to set up the shrinkage by the plastic flow direction from the gate. CAD software only allows users to set up the shrinkage by X, Y, and Z direction. That means that if the part size is large, and the tolerance is tight, it’s possible some of the dimensions will be out of tolerance.

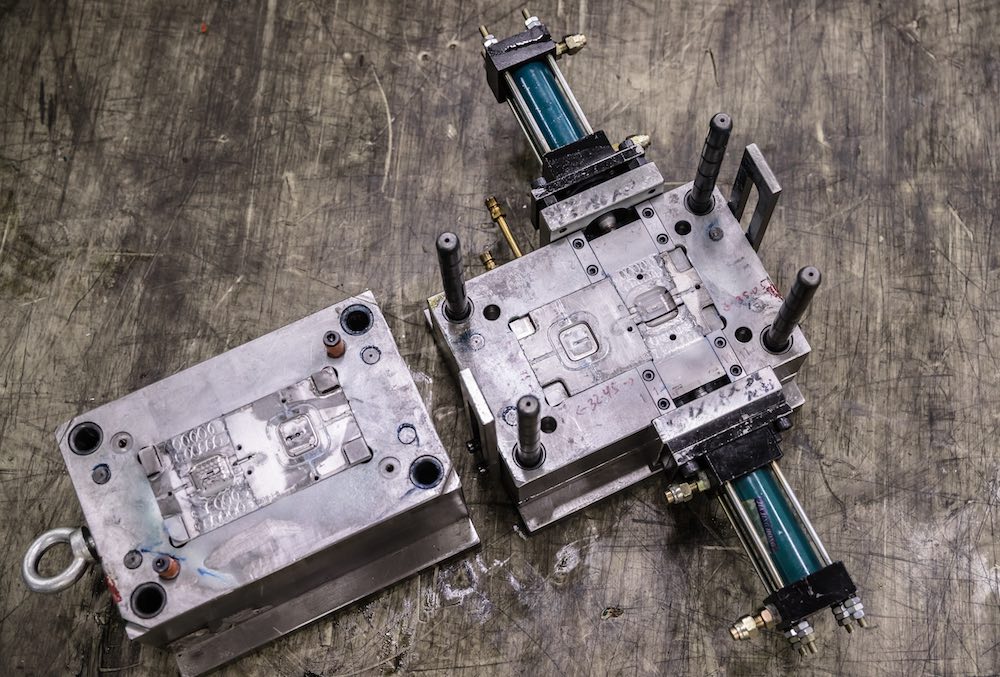

The solution is to make the mold steel-safe by leaving more tooling steel than is needed. Once the part is measured, it’s easy to remove tooling steel from the mold by CNC or EDM, but it’s difficult to add steel to the mold. To do that, you’d need to weld the mold and then remove the steel, using CNC or EDM. Additionally, welding can cause deformation of the tooling, which isn’t great for tooling life or quality of the part.

For further tooling modification, if the plastic part size is out of tolerance, you’ll need to remove or add some tooling steel from the mold to change the shape or dimension of the mold. To avoid this step, cnc aluminum test molds offer a quick, inexpensive way to make a mold, get the plastic part samples, and compare the plastic part’s critical dimensions with the print. If any critical dimension is out of tolerance, you’ll need to make a corresponding change on the production mold (the production mold will be made after the test mold). The purpose of the test mold is to figure out which dimensions will be out of tolerance and which critical features work as designed. Once you figure out how the different shrinkage in a different flow direction will impact the dimensions, you can then adjust the 3D model when you make the hard tooling.

Filled materials will abrade the mold faster than unfilled plastics, so you’ll have to use hardened steel to make the tooling’s core cavity and inserts when these materials are used. The HDT (heat distortion temperature) will also be higher, so the material could be used in a higher temperature environment. This increases the difficulty of ultrasonic welding.

In some cases, the fiber will float on the surface of the plastic part that could be visible, so most filled plastic parts are used in internal parts. To avoid this, the cavity of the mold can be textured.

How to Achieve Flexible Parts: Polyurethane (PU) vs. Silicone

Polyurethane (PU) and silicone materials offer different ways to achieve a soft part. PU uses compression molding and RTV tooling, while silicone and TPU uses injection molding. The main disadvantage of silicone is that it has flash, and when flash is cut or trimmed, there is always residue left. Additionally, when injection molding silicon, the mold has to be heated rather than the traditional process that heats the material. Injection molding TPU is easier to process, while offering similar properties as silicon.

Polyurethane (PU)

Polyurethane (PU) is divided into two categories: thermoset PU (PU) and thermoplastic PU (TPE). The main difference between the two is that a thermoset material will cross link when processed, and the material can’t be used again. Thermoplastic PU, on the other hand, can be recycled and reused. You can learn more about thermoset vs thermoplastic materials here.

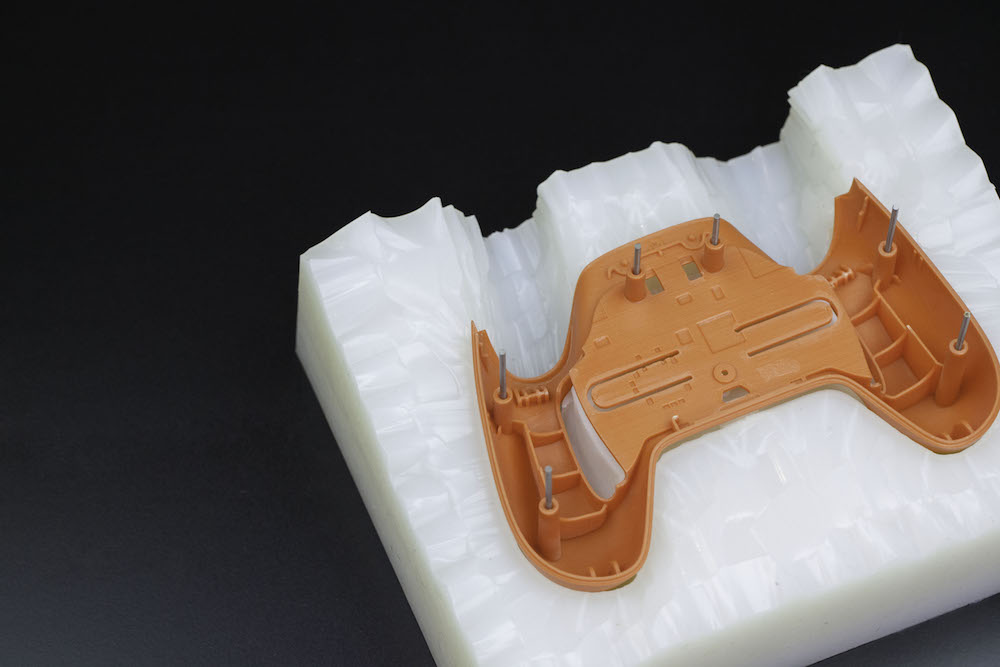

Thermoset PU is mainly used to make prototypes, via a process called urethane casting or room temperature vulcanization (RTV). Urethane casting uses a master part that is covered by a liquid silicon elastomeric material that will harden at room temperature. Once the silicon has hardened, the master is removed, and the result is a soft, flexible mold that can produce copies of the master.

Parts made from this process can range between 30A-85D. With the urethane casting process, flash is unavoidable. Normally, if the part is a hard plastic, the flash can be be trimmed manually, and the scar can be sanded, so it is less apparent. But when the part is as soft as PU, the flash can’t be removed as easily. PU has better abrasive resistance than thermoplastic elastomer (TPE) and polyvinyl chloride (PVC), so it can be used to make casters and shoe soles.

Thermoplastic PU parts can be made by injection molding, so parting lines can be very exact and precise (without flash). Thermoplastic PU’s hardness range is from 65A to 85D, so the resin can be as soft as rubber and as hard as hard plastic. Thermoplastic PU is typically used in overmolding, to make the jacks for electronics cords for example. Cords with thermoplastic PU material have much better elasticity and bending test results than cords made with PVC or TPE.

Silicone

Silicone is thermoset resin, so it has good heat resistance and weather resistance. Silicone parts are made in one of three ways: RTV casting, compression molding, or liquid silicone injection. Silicon resins can not be reprocessed or recycled.

Manufacturing Flexible Parts

As mentioned, urethane casting is the most commonly used method to make prototypes using soft materials. The hardness is around Shore A 40-50. However, only a limited number of samples can be made from a urethane cast cast mold.

Compression Molding is normally used to mass produce ordinary silicone parts. Flash is unavoidable and has to be trimmed manually. Customers can still see a scar, whose thickness from most of the thermo-compression is thicker than 0.2mm. Few factories can make it as thick as 0.1mm.

Normally, the compression molding cycle times is several minutes. The tooling material is usually steel and has many cavities, to make production efficient. When designing silicone parts, you don’t need to follow the rule of the ratio of rib/nominal wall thickness less or equal than 0.6. In most situations, even though there is an undercut, you don’t use side actions in the tooling—it can be picked out manually from the tool.

Liquid silicone injection is a process very similar to injection molding but differs in that the mold is heated to a high temperature. Normally, lead time is longer than injection molding, and the part can be as detailed as injection molded parts, which means either no flash or a very thin flash.

The image below shows the typical samples, with different hardness:

Additional Material Considerations for Injection Molding

Flowability (Viscosity)

When choosing materials, you must consider the flowability of the material. For very thin-walled parts or large parts, flowability is important.

Flowability differs for different types of resins. One kind of resin will have many different grades; for example, ABS has general grade, high flow grade, and high impact grade.

There are many different kinds of ABS material, all with different mechanical properties and prices. Some types of ABS are perfect for making parts with a high-gloss finish; some types are ideal for making electroplate parts; and some have good flowability for making thin wall parts or large size parts.

Normally, for the same resin in different grades, the higher the flowability is, the lower the mechanical property will be. The melt index (MI) represents the resin’s flowability and can be found on the trusted materials and ingredients global search engine, Prospector. Good flowability resin can be used to make thin-wall plastic parts, like a cellphone’s battery housing, or large plastic parts, like a baby bathtub.

Resins with good flowability: LCP, PA, PE, PS, and PP.

Resins with medium flowability: ABS, AS, PMMA, and POM.

Resins with poor flowability: PC, PSF, and PPO.

Mechanical Design

Engineering performance considerations determine what type of material you should use. A glass-filled resin is best for strong parts that require wear resistance and strength, like computer housings, toys, and other consumer products. In contrast, an unfilled material, like ABS or polycarbonate, works best for cosmetic parts that don’t require exceptional strength. Polypropylene or Polyethylene are ideal for designs that will be used for containers or parts with living hinges.

Dimension Stability

When designing a plastic part, you need to consider how precisely a part needs to fit with other parts. For a precise fit, it’s important to select a plastic with good dimensional stability, like PC, ABS, or POM. Neither PA nor PP would be a strong choice in this situation, as the shrink ratio, strength, and flexibility would be detrimental to the part design, which requires mating fits to other components. However, in cases when you have to use PA or PP, a nucleating agent can be added to the resin to improve the dimension stability.

Impact Strength

Impact strength represents a material’s tenacity — when the impact strength is low, it’s brittle. The impact strength can be found on the material’s data sheet and on Prospector.

Normally, recycled plastic impact strength is lower than that of virgin resin. When glass and carbon fiber are compounded with resin, the impact strength is lower, while the load and wear strength is higher.

When a new plastic part is in the design process, it’s important to think about what kind of force will be loaded onto the part, how big the force is, and the frequency of the force. For example, a hand-held electronic product can be dropped, so the product’s housing material should be PC or PC/ABS. PC plastic has almost the highest impact strength of normal engineering plastic.

Weather Resistance and UV Resistance

When the plastic will be used outdoors, the plastic part should have good weather resistance and UV resistance. ASA is a resin with good weather and UV resistance. Its mechanical properties are similar to ABS.

In situations when you have to use another type of resin, adding a UV stabilizer and weather resistance agent into the resin is an option. However any plastic resin should be tested thoroughly prior to use to ensure that it will meet the product requirements.

Temperature Considerations

It’s also important to consider temperature when selecting a resin. When an engine is working, the temperature in the engine housing is around 70-90 degrees Celsius, so all the material in the engine housing should be able to withstand that temperature. Prospector includes the UL yellow card information for various resins, including long-term usage temperatures.

Main Takeaways

There’s a lot to consider in choosing the right injection molding materials for your design requirements. When you’re ready to kickoff production and get an injection molding quote, the Fictiv manufacturing team is here to provide advice specific to your designs.

We offer free design for manufacturing feedback for injection molding, which means we’ll provide a full DFM report with your quote and are happy to setup a free consultation video call with our manufacturing engineers. Learn more about our on-demand injection molding capabilities here!