Time to read: 6 min

When I began studying engineering, prototyping involved expensive machining and milling individual pieces after careful CNC programming (of course, back then, the GameCube was hot stuff, and GoldenEye on N64 still a fun way to pass a weekend). The first 3D printer I saw used inkjet printing technology, squirting glue over consecutive layers of sand—but the prototypes were crude and easily broken. Now, we 3D print rocket engines.

But 3D printing has limitations, especially in prototyping rubber-like materials. While you have more options now than even a year ago, how do you know if 3D printed elastomers are right for your project? And if 3D printing won’t work, what are the alternatives?

Overview of Rubber Prototyping Methods

In addition to 3D printing are two common, if old-fashioned, methods to prototype rubber materials: molding and milling. Each process has areas where they shine—and designs where they’re absolutely the wrong choice. We’ll start with the narrowest application: milling elastomers. (Quick note: Though “rubber” often references naturally-derived elastomers, we’ll use “rubber” and “elastomer” interchangeably.)

Milling Elastomer Prototypes

CNC milling elastomers is limited for one major reason: Cutting something that’s constantly bouncing back is difficult. Milling rubber is only effective when the elastomer is nearly rigid. Anything softer than the hardness of a shopping cart wheel will be pushed around by the cutter, instead of being shaped. Often, milling molds for a cast urethane prototype is easier than milling the rubber directly.

If you absolutely must try milling your rubber prototype, machinists have some tricks. To keep the elastomeric prototype part from squeezing away from the cutter, put a collar just above the blade; the collar can “float” on the rubber part, keeping it from lifting away. Another cool trick is to freeze the elastomeric part in liquid nitrogen, temporarily increasing its hardness.

Keep in mind that even with these tricks, the detail on the rubber prototype parts will be poor, so if you need high-resolution geometry, you’re better off with another option. Which brings us to…

Molding Elastomer Prototypes

This may confuse some young engineers: Until recently, molding was the only option for quality elastomer parts. Of course, when I was a kid, NES was the only option for quality home gaming. Times change, but just as Super Mario will always be a favorite, cast urethane still has a place in today’s manufacturing.

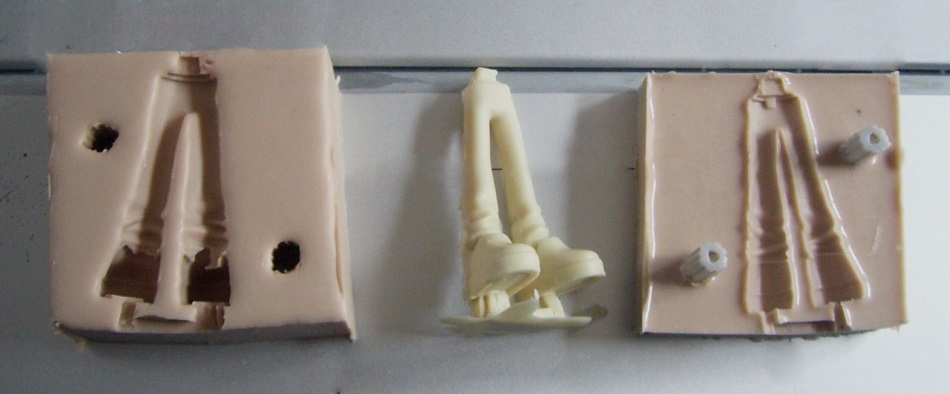

Creating molds was once a two-week process but now can takes less than two days. First, a master part must be created, with the exact geometry of the final parts. In the past, the part was CNC milled, but now the master can be 3D printed. Then, RTV (room temperature vulcanizing—curing without being heated) silicone is poured around the master part and allowed to harden. Finally, the silicone mold is cut into an A and B side, the master is removed, and voila! A mold.

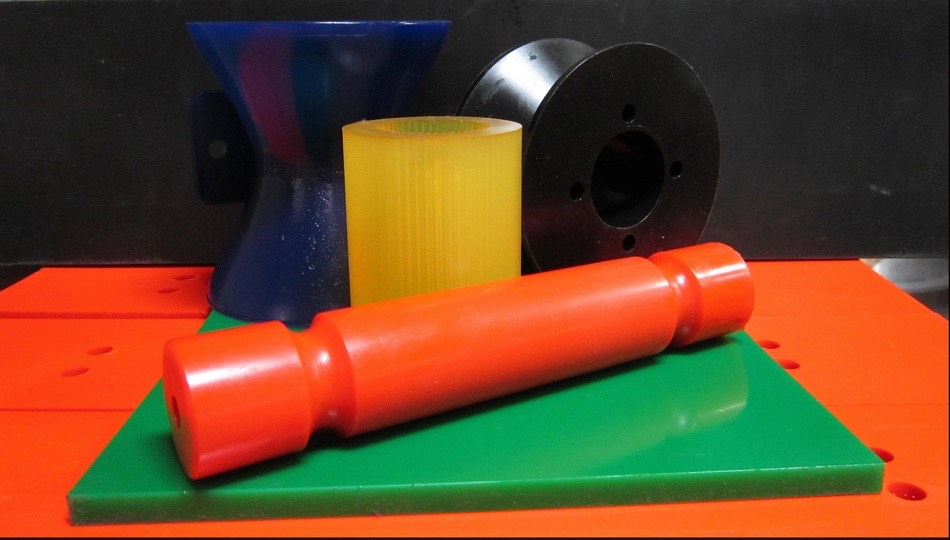

The biggest advantage of this method is that the silicone mold can be reused many times, so urethane casting is used for low-volume production, too. And with all the available urethane compounds, you have a virtually unlimited selection of properties, such as durometer and temperature use.

The drawback is that even with a 3D printed master, the process is still long to get even one elastomer prototype. Which is why, for those of us old enough to remember, 3D printing is such a miracle. (Just like Geralt’s hair movement in The Witcher. Blows my Mario-loving mind.)

3D Printing Elastomer Prototypes

Finally, 3D printing elastomer prototypes—what you’ve all been waiting for—or rather, what we’ve all been waiting for. This technology is still new (even by 3D printing standards) and imperfect, but nevertheless, it’s amazing. It isn’t perfect for all applications, though, so let me guide you through your decision for your design.

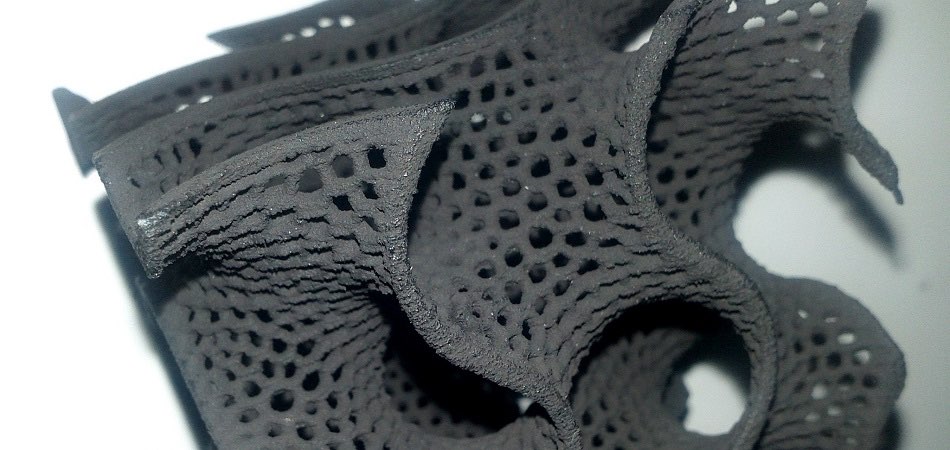

The older method of simulating rubber used selective laser sintering (SLS) with a flexible base, which resulted in an elastic part. However, the parts are still quite stiff, have low stretch, break after repeated flexure, and have a low resolution finish—not ideal for many prototypes. Until recently, this was the best that could be hoped for, but newer materials are making their way into the market.

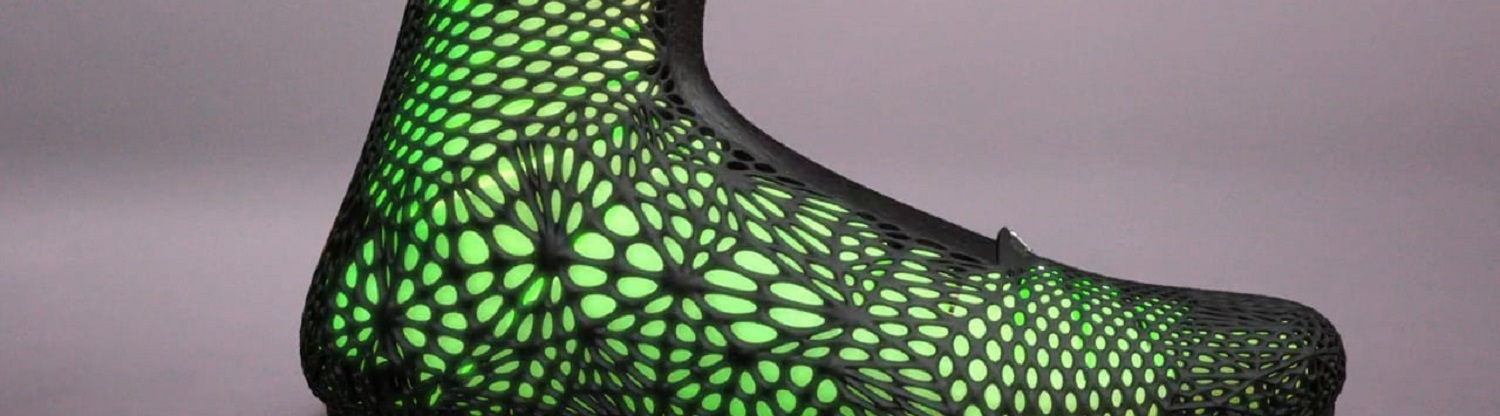

An incredible advance in printing came with PolyJet technology. With multiple materials coming from the same head, in countless combinations, PolyJet not only can accurately simulate rubber properties, but it can also simulate over-molding—where a rigid part is partially or fully covered in a rubber-like material—which used to be particularly difficult to prototype.

Add the fact that PolyJet materials can simulate elastomer prototypes ranging from 27-95 shore A, and it seems like a nearly perfect material. Unfortunately, before you decide to go with this material, you do have to look at requirements for final strength: Some of these rubber-like materials (like Tango) are still in early development and lack the strength of true rubber parts, so use some caution. But for higher strength and better functionality, new materials like Agilus are being developed that are closer to true rubbers.

An even newer printing technology for elastomer parts has exploded onto the scene within the last two years, with the advent of CLIP (Continuous Liquid Interface Production) printing, which allows for more consistent isotropic properties in 3D printed parts. Using real polyurethane, the Carbon printers yield production-quality rubber parts, with one major catch: Because the materials and processes are so new, the only commercially available hardness is 68 shore A. That limitation, the fact that the technology is quite expensive, and the fact that few sources exist for the printed parts mean that this may not be the right technology for your parts now, but you should definitely keep an eye on further development.

Choosing the right process for your parts

Now for where the rubber meets the road (forgive me, I had to): What process should you use to create your elastomer prototype? While of course that’s different for each design, the areas to look at remain the same: cost, production volume, required functionality, and hardness.

For low-cost prototypes, especially with lower strength or resolution requirements, SLS is a reasonable material choice. Very slightly more expensive, but with great resolution, PolyJet Tango makes parts with the right feel, even if they’re not as strong as production parts. Closer to production, but again slightly more expensive, is the PolyJet Agilus material, which gives broad choice in durometer and amazing elongation (more than 200% before breaking).

With the requirement of a master part, mold creation, and finally casting the prototype, cast urethane is a costly option, but it’s unparalleled if you’re looking to create many prototype parts. Milling is rarely recommended, but reasonable for low-detail parts in very hard rubbers.

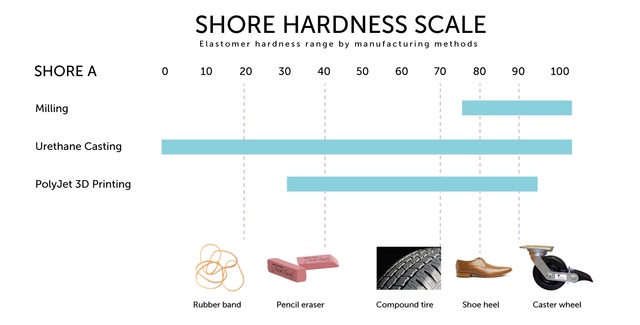

For any of these processes, there are a number of durometer ranges that can be created, but listing properties makes for damn boring reading, so we’ve created a simple chart that illustrates the durometers at a glance:

With the rapid development of 3D printing technology, I expect that my advice on alternatives for prototyping rubber will soon be arcane, much like my esoteric abilities in Donkey Kong Country (still one of the best games ever). But until that happens, take the time to consider these other methods of prototyping your parts and see which is best for your project.

Need more info on designing your elastomer design? Be sure to check out our silicone design guide, and remember to sign up to have tips like these regularly delivered to your inbox. And of course, if you need to convince your boss of your choice of a certain prototype method for your design, feel free to forward her this article!