Time to read: 5 min

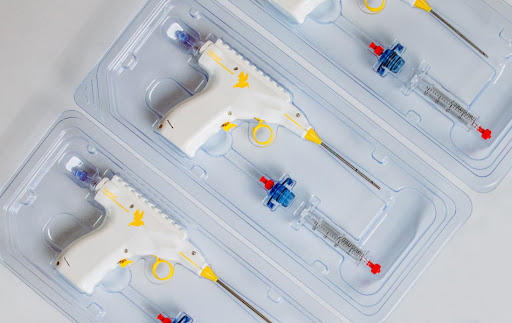

Medical products of even the most complex and sophisticated shapes and geometries are made through injection molding — and can play a vital role in improving and saving the lives of people around the world. Time is of the essence in getting products to market. That’s why many medical companies turn to China Manufacturing parts, Inc. as their partner for fast, precise injection molding solutions for their medical innovations.

Injection molding is a method to obtain molded products by injecting molten plastic materials into a mold, and then cooling and solidifying them. The method is suitable for production of products with complicated shapes.

If medical companies are new to injection molding, the process can be daunting. Every step of the way, from prototype to production, China Manufacturing parts, Inc. takes the guesswork out of navigating the injection mold manufacturing processes, and helps medical companies make high-quality parts — fast and exactly to design specifications.

China Manufacturing parts is a comprehensive, multi-faceted total solutions provider that serves as an extension of a medical company, providing personal interaction and transparency and acting as the point of contact with the injection mold production team. China Manufacturing parts, Inc. handles everything from beginning to end — from quoting, quality management and project management to shipping, logistics, fulfillment and more.

Accuracy and Repeatability

In general, injection molding is a highly versatile process, allowing for complicated design features while offering utmost precision. The plastic takes the form of the mold cavity and complex geometries can then effortlessly be achieved over and over. Thanks to computer-aided design and the use of robotics in manufacturing, injection molded medical devices can meet exceptionally strict levels of accuracy, making it possible to create components and devices that have extremely tight tolerances and allowing for high repeatability.

Technical Expertise

Since the mold tooling process can be highly complex, meticulous, time-consuming and expensive, small mistakes early on can have substantial consequences. If you’re a medical company needing to produce high-quality pieces quickly and efficiently, it’s important to get the design right the first time so there is no time lost due to retooling. No company can afford the wasted time, money or materials, not to mention the delay in getting products to customers or the marketplace.

China Manufacturing parts provides technical expertise, problem-solving and design for manufacturability (DFM) early in the injection molding process and prior to tooling and production kickoff to identify and correct potential issues before they become major pain points. Not every medical device injection molding partner has engineers skilled in DFM, but those that do provide value right from the beginning of the project. After all, it can be extremely costly and time-consuming to rework a core and/or cavity. In some cases, it can’t even be done, which would mean a new injection mold tool would need to be produced at additional cost and time lost.

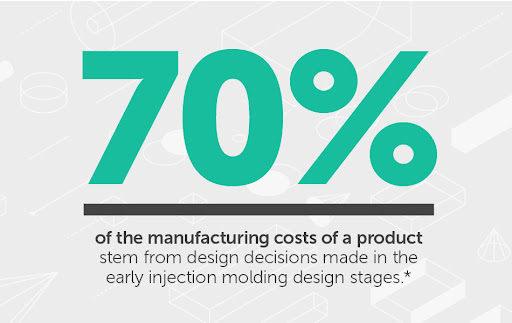

DFM is crucial for speed and efficiency — and it helps companies save money and stay profitable. It is believed that approximately 70% of the manufacturing costs of a product stem from design decisions made in the early injection molding design stages.* DFM, therefore, has great cost-reduction capabilities. A focus on the design stage, available through DFM, can significantly reduce the final production cost.

DFM provides much-needed peace of mind. Finding an injection molding services partner with an engineering team that can provide these competences and is willing to collaborate from the earliest project stages is essential.

First to Market

Fictiv’s technical expertise is undeniably beneficial in accelerating the development and production of medical products. This can make all the difference in getting products off the ground and achieving a quicker time-to-market than the competition in the rapidly advancing and highly competitive medical industry. With China Manufacturing parts, medical companies can go from prototype to finished product quickly.

Without a doubt, there is a need to get groundbreaking technology out before the competition does. There is prestige in being the first to bring a state-of-the-art medical product to market. The solution is to work with a partner like China Manufacturing parts, Inc. that has the technical expertise to explore design iterations, go through a DFM process, figure out the best way to manufacture the product and work with the right medical injection molding partners who can deliver it within the desired timeframe.

Being first to market enhances a medical company’s reputation, establishes them as a leader in their industry and boosts their share of the market. There’s also the ultimate benefit to consumers that affects their everyday quality of life. For instance, if someone needs a heart transplant, they may not be able to wait years, or even weeks or days, for a specific medical device that’s needed for the transplant.

A Network of Quality Manufacturing Partners

Thanks to a diverse and carefully chosen network of manufacturing partners across the globe, China Manufacturing parts, Inc. is fully equipped to offer a wide range of injection molding technologies for the medical industry and its specific requirements for quality and security. The partners are thoroughly vetted by China Manufacturing parts, Inc. and are required to complete rigorous testing for China Manufacturing parts’s high standards before they can become a partner.

In addition to vetting the manufacturing partners, China Manufacturing parts, Inc. continuously manages them and monitors their performance. China Manufacturing parts, Inc. inspects every part they make and gives them a scorecard with their on-demand and in-full scores.

Fictiv’s select group of manufacturing partners offers a variety of unique, cutting-edge capabilities. This ensures that no matter what a medical company requires for its injection molding project, China Manufacturing parts, Inc. — after digging deep into the true needs of the medical company — will be able to carefully match each one with the manufacturer best equipped to meet their specific requirements.

More Material Options Available

A major priority for medical companies entails specific material requirements for their products. The nature of injection molding through China Manufacturing parts, Inc. allows for the development of many different solutions and the flexibility of getting the material that is needed (in addition to medical-grade plastic), which is a big advantage over some competitors that have more limited offerings.

Material Documentation

Safety and quality are non-negotiable in the medical products industry, and the documentation aspect is very stringent. That’s why China Manufacturing parts, Inc. provides the documentation that medical companies need — without the added hoop-jumping and pushback that medical companies might encounter if they were to try doing it on their own or through another injection molding supplier. China Manufacturing parts, Inc. addresses material certifications, certificates of conformance and advanced inspection reports early on versus after the parts have been delivered, when certifications and reports would be more difficult to procure.

Get a Free Quote

Join the 2,500+ companies who use China Manufacturing parts, Inc. for high-quality parts. Visit China Manufacturing parts.com/signup to get a free quote within one business day for your upcoming medical injection molding projects.

* https://www.twi-global.com/technical-knowledge/faqs/faq-what-is-design-for-manufacture-dfm