Time to read: 3 min

It’s December and while most people are giddy with the holidays upcoming, consumer electronic companies around the world are in crunch-time preparing prototypes for the annual Consumer Electronics Show (CES).

It can be a stressful time of year for engineers and designers, so here are a few prototyping tips to help you understand all your options for December fabrication needs.

1. Consider Spray Painting as a Finish for Visual Models

People often think of spray painting as a low-end finish, but if you know the right circumstances in which to use spray painting, it can look just as good as a professional paint booth job.

Note that the main drawback of spray painting is durability, so if your prototype is going to be touched and handled constantly, spray paint will show wear-and-tear quickly. However, If the prototype is going to sit away from people’s hands, it will look fantastic.

Spray Painting Tips:

- If your prototype is 3D printed, opt for a high resolution material like VeroWhite

- Always sand down the surface until it’s perfectly smooth and clean before applying paint

- Use a primer for a good bonding layer between the plastic and the paint

- Wet sand after each primer layer

- Use good paint — we recommend Montana Colors Spray Paint

- Use a Polyurethane Clear Coat as a final layer for protection and gloss

Check out our Ultimate Finishing Guide for more tips.

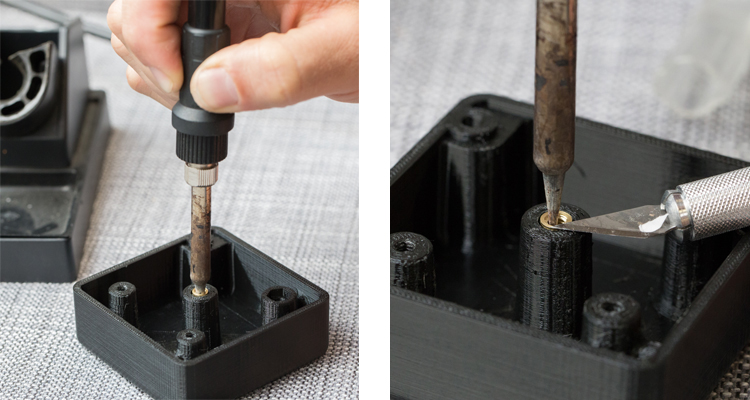

2. Heated Inserts are a Great Option for Enclosures

If you’re building an enclosure, it’s likely you’ve designed it with either snap fits or threads for a secure fit. But If you’re running against a tight deadline, you might consider using brass heated inserts instead.

If not designed perfectly, snap fits can easily fracture and leave your enclosure useless. And to get holes tapped for threading, it’s typically a slower process requiring some back-and-forth with your vendor.

Heated inserts can be easily installed in a few minutes with nothing more than a soldering iron, making it a great option in a pinch. Check out our how-to guide here.

3. Plan For Delays at Customs

This time of year is not only busy for consumer electronic companies, but also shipping and customs agents around the world. With the holiday season, expect delays if you’re ordering internationally. We’ve seen orders placed in mid-December delayed by up to a month at customs before finally being shipped out.

To prepare, be sure to (over)communicate with your overseas vendors to find out what shipping options you have. Timelines and delivery processes can change depending on size, weight, quantity and value of the order.

+ Check out these tips from DHL

4. Reach out to Machinists Before December 15th

Just like you, machine shops are feeling the weight of CES. It’s not uncommon for vendors to refuse work the weeks before CES due to capacity constraints as well as vacation time. Even overseas, several quick-turn prototyping shops implement cutoff dates to guarantee delivery of your parts for the annual tradeshow.

So be sure to reach out to your vendors early, to avoid any unexpected production delays.

5. Leverage China Manufacturing parts’s Prototyping Engineers for Questions

Whether you’ve used China Manufacturing parts, Inc. in the past or not, one of the awesome features you can take advantage of is access to our Prototyping Engineers and Manufacturing Consultants for free, right through our online live chat feature. Send us any and all questions — we typically respond in less than 5 minutes.

Best of luck and see you at CES!