Time to read: 7 min

We’re insulated from the cost of our garbage in America. As kids, we were trained to carefully place trash in the cans lining our streets. I’ll never forget the shock of seeing that same trash scattered along the streets in urban West Africa, but it did get me thinking: They can see their waste. What if we had to live next to all the refuse we generate? The good news is that companies are striving to minimize packaging on our frequently used items, developing sustainable packaging designs for beverages and everyday foods. However, working in the consumer electronics field, packaging design does more than carry our product: It carries our brand. How do you maintain brand image while creating planet-healthy packaging designs? The key is to think about the whole lifecycle of every element of the packaging design.

Lifecycle Thinking: Cradle to Grave

“Where do we come from?”

“What is our purpose?”

“What happens after life?”

No, I’m not having an existential crisis—these are the questions we must ask about each component of our packaging design and about the materials we choose to use. What is the material source? What are the most important aspects of the design? What will happen to these pieces once they have served their purpose? Breaking the packaging design lifecycle into these areas allow us to examine each against our criteria for sustainable design, giving us a holistic picture of our choices.

Material Sourcing: The Cradle

We’ll start at the beginning when examining designs for sustainability. Of course, the best sustainably sourced materials are post-consumer materials that are in their second (or later!) life as a useful product, reincarnated as a cradle for your electronics. Luckily, emerging technologies have made it possible to create beautiful packaging design with recycled materials that can even add to your brand message.

Ten years ago, most new electronics came supported in a made-to-order molded plastic cradle. These days, many companies are turning to molded pulp, an eco-friendly alternative that functions just as well but can be made with recycled paper. Though the dry-pressed pulp looks like an egg carton, the wet-pressed pulp looks great in high-end electronics designs and is easily dyed to adapt to even a colorful brand aesthetic.

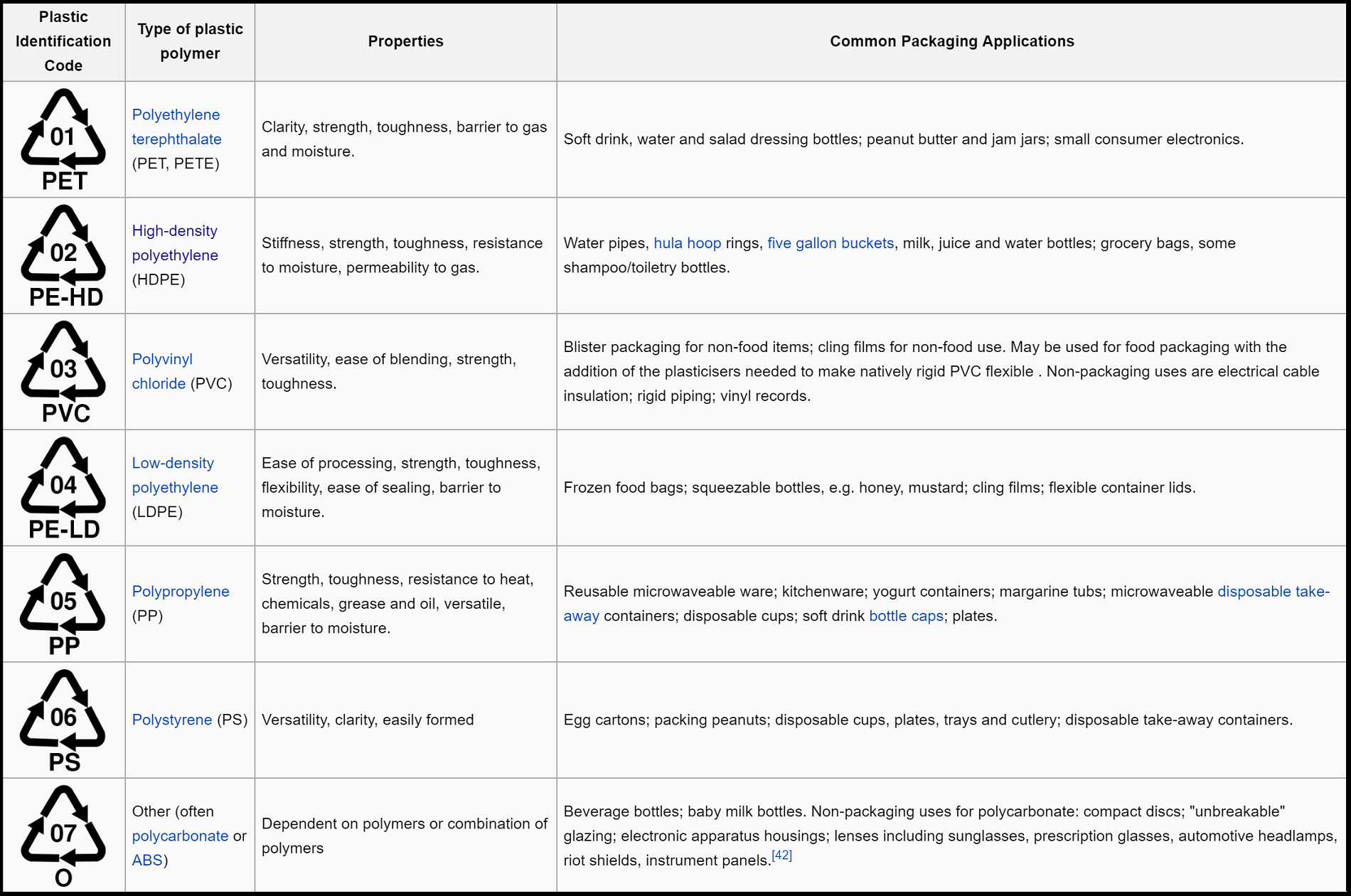

Recycled plastic is another great material for packaging electronics and one that’s abundantly available, with recycled PET a great option for clear packaging and HDPE for less translucent and fully opaque applications. Even more interesting, with the growing mass of plastic floating in the Pacific, a number of companies are turning to this plastic as a source for recycled material in new products. How amazing would it be to actually save aquatic life with your packaging?

Another packaging pitfall we’ve been able to (mostly) say goodbye to is the use of foam peanuts. As much fun as they were to scatter throughout the house for your parents to clean up (I love you, Mom!), adding shock absorption for rough handling is another great application of recycled paper, this time shredded instead of pulped. It’s fluffy, it doesn’t stick to the cat, and it will protect your electronics nearly as well.

Of course, if you really need the shock absorption of foam, you should consider materials made from corn starch and other bioplastics, which are especially great when you consider the end of life (but I’m getting ahead of myself; read on!).

One caution: look at the reality of a material versus the appearance, especially when considering “natural” versus “sustainable” materials. Few things look quite as beautiful as a tropical hardwood box, but we obviously know that cutting down an Amazonian tree for delivering a new electronic device isn’t even remotely good for the planet—but not all cases are quite as clear.

It’s often better to choose a synthetic material, even though natural materials feel more eco-friendly. This recently came to the attention of many consumers attempting to do a good thing by replacing plastic shopping bags with cotton, only to find out that it would take more than 130 uses for the bag to repay the environmental cost, while a similar bag of synthetic polypropylene bag is a net environmental benefit after just a dozen uses. Choose carefully.

Of course, sustainable packaging requires more than just looking at the source. How will your materials be used in your packaging designs?

Efficiency and Use: The Purpose

What is the purpose of your packaging? Is it to entice users to purchase at a retail location? Is it to create a memorable unboxing experience? Or is it just a way to protect your electronics during shipping?

Sustainable packaging design is minimalist, which fortunately fits well with modern design philosophy, even outside the environmental movement. Consider ways of eliminating packaging components, as well as minimizing the use of materials within each component.

I know you want your earbuds to be prominently displayed, but is it really necessary to package them in a Dostoyevsky-novel sized box, when Sennhesiser is doing such a beautiful job with small, stamped cardboard boxes? And not all watches need bulletproof cases surrounding them; could your sports-related electronics brand be better represented with a playful cut-cardboard box?

Even top-tier electronics like computers can be packaged in a more sustainable way, in a form-fitting box that doubles as its shipping container, as demonstrated recently by the appropriately-named Litl webbook. One of the best things about slimming down the package itself is that this single change has a trickle-down effect on reducing the number of pallets required for shipping, which saves on the environmental cost of shipment, not to mention the company’s bottom line.

Thinking beyond delivering the product to the end user, can your packaging design be used in another application within the consumer’s home? I was thrilled when the bag that I was given to carry my laptop home from a Microsoft store was actually a large, reusable shopping bag—it’s the primary bag I use for my weekly shopping trips now. Besides my own glee at the bonus, Microsoft is getting free brand publicity every time I go shopping.

Microsoft isn’t the only one taking advantage of the continued lifespan of packages: A car-tracking adapter comes packaged in a bonus travel cup, and Motorola announced a soon-to-be-released design for the package on an upcoming phone that will double as a charging stand during the phone’s life, then can be used a shipping container (with the included prepaid envelope), once your phone is ready to be recycled. Speaking of recycling, what happens to your design when it’s served its purpose?

End of Life: Recovery

As I mentioned earlier, ideally all the materials in your design will be recycled again and again, being reincarnated into a variety of new designs as the years pass (of course, this means that they can’t clear their karmic debt and achieve packaging nirvana, but that’s their loss). As much as it sounds like a utopian ideal, in reality, recyclable packaging isn’t really too complicated.

Material selection is important, as only some types of plastic (look especially at HDPE and PET, recycled as no. 1 and no. 2, which are more easily recovered than other types) and paper are easily recycled. Equally important, though, is avoiding mixing materials. Think of the categories an average household will need to separate: metals in one bin, plastics in another, paper in a third, foam peanuts on the cat (kidding!).

Now what do you do with a plastic bag with a shiny metal lining? It goes in the trash. A paper container with plastic coating? The trash. Two materials that could be recycled separately become nothing but waste when combined together. It’s important to make separation easy and clearly label the different materials for recycling in the appropriate way.

Another possibility with materials at end of life are compostable materials, such as certain types of pulp and bioplastics. Some enterprising designers even mix flower seeds into packaging, so that the packaging blooms in your yard once planted (how’s that for nirvana?). Just a quick warning on the bioplastics, though: If the consumer can’t throw these into an actual compost bin, where temperatures of 50 degrees Celsius or more are required for adequate breakdown, these plastics can still end up in landfills for centuries. You’ll need to do some careful research on the materials you intend to use and consider your market.

Prototyping Your Packaging Design

While some of the materials discussed here will need final-form testing, even at the prototoyping stage, for any molded material (from pulp to recycled ocean plastic), 3D printing is a great way to inexpensively test your designs. For the aesthetic and fit tests especially, PLA is a great low-cost material to use for early design stages. And when prototyping cut cardboard or folded designs for boxes (from paperboard to PET plastic), laser cutting the designs is a great way to test small quantities and refine the packaging experience.

The Future of Sustainable Design

A move to sustainability won’t be easy in any field, but we can be glad that so many emerging technologies are laying a foundation in the direction of sustainable package design. There’s never been a better time to move forward in designing a cradle for your electronics baby that will also support the life of the planet.

And even though right now we look at designs linearly, from manufacturing to use to end of life, at least one man is leading a school of thought that looks at recycling more holistically, the way leaves and animal waste enable the life of a forest. If you have a chance, William McDonaugh’s seminal work, Cradle to Cradle, is a great read. And you know what else is a great read? The China Manufacturing parts, Inc. blog. Send a link along to a coworker today, to help inspire them to work towards a greener planet.