Time to read: 4 min

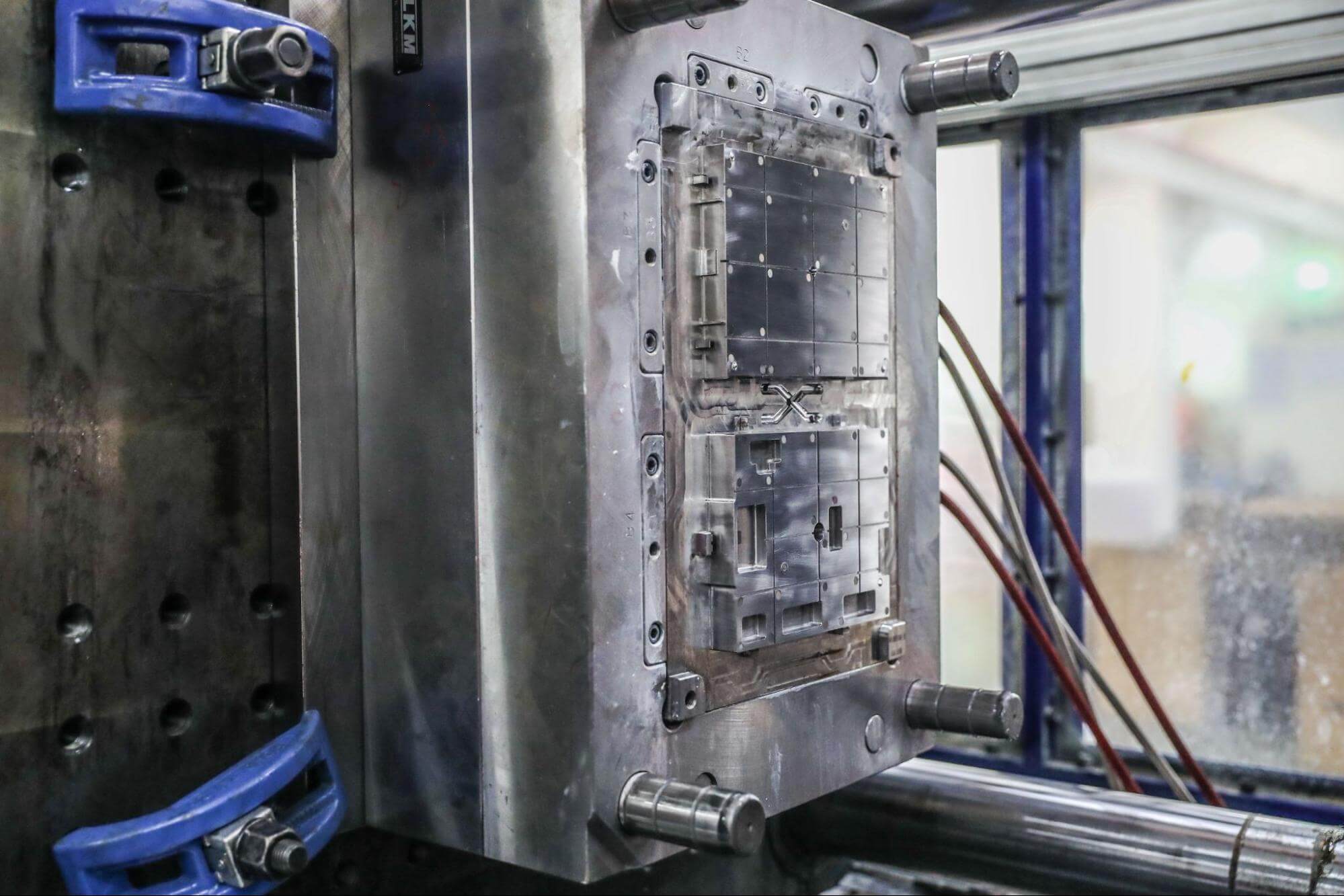

ABS is a commonly used plastic injection molding material with three main ingredients: acrylonitrile, butadiene, and styrene. Each of these monomers imparts specific properties and provides ABS terpolymer with a robust combination of features. The “A” in ABS, acrylonitrile, imparts hardness and heat and chemical resistance. The “B”, which stands for butadiene, provides toughness and impact resistance. The “S”, for styrene, offers gloss, strength, and processability.

ABS plastic is relatively inexpensive to purchase and relatively easy to injection mold. It’s often used in consumer goods and electronic components, but isn’t the best choice for outdoor applications since it lacks strong resistance to sunlight and weather. However, ABS does support the use of additives that can increase its resistance to ultraviolet (UV) light. Filler materials can also be added to Injection molded ABS for added strength. Filler materials include glass, nylon, acrylic, and stainless steel fibers.

Additives and fillers can affect processing parameters, however, and different grades of ABS may contain different combinations of acrylonitrile, butadiene, and styrene. That’s why it’s important to partner with an ABS injection molder who understands more than just the advantages and applications for this popular plastic. The material properties of ABS and the way that it’s processed are critical to the success of your project.

Material Properties

Like other injected molded plastics, ABS can be characterized in terms of typical material properties. Two physical properties, mold shrinkage and water absorption, are especially important because of their relationship to drying and processing. There are also injection properties that molders need to consider in order to avoid part defects.

The table below provides typical values for a generic ABS material containing glass beads.

| Physical | Nominal Value |

| Mold Shrinkage – Flow (73°F) | 4.0e-3* to 7.0e-3** inches |

| Water Absorption (24 hr., 73° F) | 0.16 to 0.25% |

| Mechanical | |

| Tensile Modulus (73° F) | 3200 to 500 kpsi |

| Tensile Elongation (Break, 73° F) | 2.0 to 10% |

| Flexural Modulus (73°F) | 348 to 426 kpsi |

| Flexural Strength (73° F) | 7150 to 9100 psi |

| Injection | |

| Drying Temperature | 176 to 180 F |

| Drying Time | 2.0 to 9.0 hr. |

| Melt Temperature | 410° to 500° F |

| Mold Temperature | 113° to 175° F |

*4.0e-3 = 4.0 x 10-3 = 0.0040

**7.0e-3 = 7.0 x 10-3 = 0.0070

Material Processing Concerns

As the water absorption values in the table above show, ABS tends to absorb moisture. Therefore, it must be fully dried before processing, which adds time and costs — but failing to remove moisture can result in molded parts with cloudiness, bubbles, or surface lines. If your parts require a high gloss, highly reflective surface, more than nine hours of dry time may be required.

Viscosity

Melt temperature is another important processing consideration because of its relationship with viscosity, a measure of a fluid’s resistance to flow. If ABS pellets are melted beyond their plasticizing temperature, viscosity increases and the material becomes more difficult to mold. This behavior differs from other amorphous plastics, where viscosity decreases beyond the plasticization, or processing, temperature.

Temperature Control

ABS that is overheated is also subject to thermal decomposition, the heat-induced breakdown of chemical bonds. Brown granules on injected molded parts mean the molding occurred at excessive temperatures, which is often caused by old equipment with poor temperature control. For injected molded ABS parts with higher gloss, however, higher molding temperature must be maintained without damaging the material. The temperature of the mold itself is also higher with ABS than with other commonly used materials.

Injection Pressure

Because of ABS’s viscosity, higher injection pressures are needed than for many other materials, but lower pressures may still be suitable for smaller, simpler, or thicker products. Just bear in mind that if the injection pressure is too high, increased friction can cause molded parts to stick, which complicates their removal and adds to production costs. If the pressure is too low, mold shrinkage increases and can result in out-of-tolerance parts that won’t meet end-use requirements.

Injection Speed

Injection molding speed is another important processing consideration. If the speed is too fast, ABS plastic may burn or thermally decompose. The results can include defects such as weld lines, poor glossiness, and discoloration. If the injection molding speed is too slow, however, there may be insufficient filling of the mold. For improved dimensional stability, the shot size that is required with ABS is less than with other plastics. This reduces material usage but still requires proper processing techniques.

Succeeding with ABS Injection Molding

ABS is a commonly used injection molding plastic, but that doesn’t mean just any manufacturing partner can produce the parts you need. Many injection molders can describe its advantages and applications, but don’t understand ABS’s material properties and processing considerations. And you don’t want to deal with the added processing costs, risk and part defects that come with inadequate drying or improper processing methods.China Manufacturing parts has the resources, experience, knowledge and production network to deliver the parts you need, fast. Create an account and get an instant quote today!