All articles from the author

Article

Product Study: Undercuts in Injection Molding

The Challenge: Avoid Unnecessary Costs and Complexity Injected molded parts that have recessed features called undercuts are more difficult to eject during manufacturing. This adds costs and complexity to tooling, and undercuts that are too deep may be especially hard to remove. Yet, some product designs use undercuts for a fastening point or locating edge. […]

Article

Common Mistakes in Injection Molding Design

Injection molding design mistakes can cost you time and money. If there’s a problem with the design of your injection mold, you may need to modify or discard your tooling. And that means paying for and waiting for a replacement tool – which will delay the start of production accordingly. Plus, if there’s a problem […]

Article

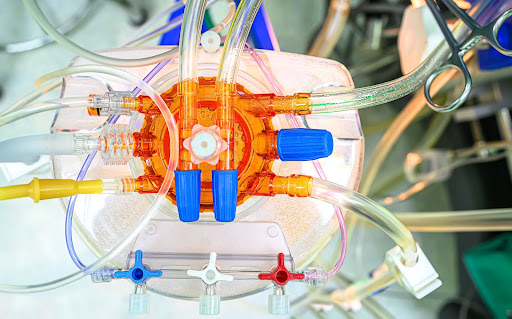

Product Study: Cost-Effective Medical Injection Molds for Lower Volumes

The Challenge: Manufacturing Process Tradeoffs for Medical Product Development Plastic injection molding (IM) is ideal for high-volume manufacturing, but not all medical injection molders can provide tooling that is cost-effective for functional prototypes and low-volume production (LVP.) As a result, medical product designers may be forced to use another process during these stages of the […]

Article

Prototyping and Low-Volume Production for Medical Devices & Applications

Prototyping for medical devices and applications produces functional samples for testing and evaluation. These samples can be used to advance a product through regulatory gates, or approval stages, but that’s not the only reason why medical prototyping is necessary. Designers can apply what they learn and make changes, including improvements for manufacturability. When prototyping is […]

Article

Product Study: How Medical Companies Can Leverage China Manufacturing parts’s Broad Access to Medical Plastics

The Challenge: Materials That Meet Multiple Requirements Medical product designers need materials with more than just the right properties and price points. They may also need to consider approvals from regulatory agencies and meet traceability requirements. Although metals, ceramics, and composites are used in some medical applications, plastic injection molding provides designers with a broad […]

Article

Product Study: How Medical Companies Can Leverage China Manufacturing parts’s Precision Injection Molding Expertise

The Challenge: Tight-Tolerance Parts That Check All the Boxes In the medical industry, a few millimeters or microns can make the difference between an injection molded part that’s functional and a quality assurance failure. Precision injection molding can produce the tight-tolerance parts that the medical industry requires, but the tools can cost more and take […]

Article

Pros & Cons of Plastic Injection Molding for Medical Products

Why is plastic injection molding used to produce many medical products? It’s a proven manufacturing process that supports high-volume production with low per-part costs. Injection molding also supports design and manufacturing complexity with part-to-part integrity. Yet not all medical devices and equipment are injection molded. In fact, there are some medical products that don’t contain […]

Article

Injection Molding for the Medical Industry

Is it time to inject more accuracy, versatility, quality, and cost-efficiency into your medical manufacturing project? Then injection molding might be just what the doctor ordered. This proven production method can create high volumes of tight-tolerance parts from a wide variety of polymers, including medical-grade plastics that meet tough regulatory requirements and testing standards. Whether […]

Article

Draft and Texture in Plastic Injection Molded Parts

It’s always a good idea to go through several drafts of any design before finalizing a part. Prototyping can help you get the right design, but you’ll need a different type of draft for a successful injection molded plastics project. In injection molding, draft is the angle that you apply to the vertical walls of […]

Article

What Causes Injection Molding Flash and How to Prevent It

Flash. It’s what you get when there’s a problem with your injection mold or with the injection molding process itself. Although flash can be addressed during post-processing, you may decide that it’s better to prevent mold flash in the first place. That’s often a function of tooling costs since flash-free molds are more expensive. For […]

Article

What You Need to Know About Injection Molding Gates

Is your injection molding project ready for success? Sure, you’ve thought about most of the injection molding manufacturing process. You’ve designed your mold with care, researched and selected the right material, and finished your CAD file or part drawing. But have you considered the type of injection molding gate to use? A gate might seem […]

Article

ABS Injection Molding: Material Properties and Processing Considerations

ABS is a commonly used plastic injection molding material with three main ingredients: acrylonitrile, butadiene, and styrene. Each of these monomers imparts specific properties and provides ABS terpolymer with a robust combination of features. The “A” in ABS, acrylonitrile, imparts hardness and heat and chemical resistance. The “B”, which stands for butadiene, provides toughness and […]

Article

A Beginner’s Guide to Post-Processing for Plastic Injection Molding

Post-processing improves the properties of plastic injection molded parts so that they are ready for end-use. It includes corrective actions that remove surface defects and secondary processes for decorative or functional purposes. For example, post molding operations can remove excess material (known as flash) or apply part numbers. As its name suggests, post-processing always occurs […]

Article

The Ten Most Common Plastic Injection Molding Materials

Plastic injection molding materials have names that sound like terms from chemistry class. It’s hard enough that polyethylene rhymes with polypropylene, which has an abbreviation (PP) that’s similar to polystyrene (PS). Choosing the right injection molding material also means knowing your application requirements, which can change between prototyping and production. Fortunately, you don’t need a […]

Article

Checklist: Know When You’re Ready to Go from 3D Printing to Injection Molding

It’s not always easy, but don’t make it harder than it needs to be. Moving from 3D printing to injection molding isn’t as simple as just using your computer-aided design (CAD) file with a different piece of equipment. Because 3D printing offers greater design freedom than injection molding, you may need to modify your CAD […]