Time to read: 4 min

Flash. It’s what you get when there’s a problem with your injection mold or with the injection molding process itself. Although flash can be addressed during post-processing, you may decide that it’s better to prevent mold flash in the first place. That’s often a function of tooling costs since flash-free molds are more expensive.

For part designers and engineers, it’s important to understand what flash is and why it occurs so that you can prevent, or at least minimize it. Partnering with an experienced injection molder is part of the solution, but you’ll also have to make decisions about the amount of flash you’re willing to accept since there are tradeoffs between quality and costs.

What is Mold Flashing?

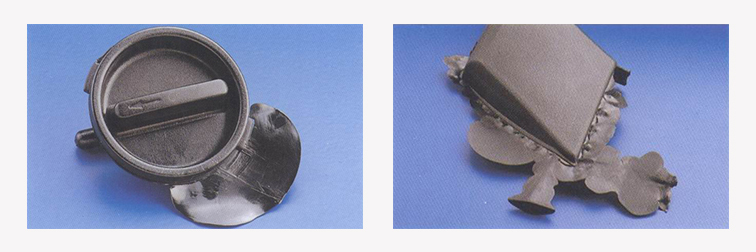

Mold flash, or flashing, is excess plastic that forms on the surface of injection molded parts. This unwanted material is usually forced out of the mold cavity at the parting line but can also emerge from other locations.

Although some amount of flash is considered to be a normal part of the molding process, excessive flash can mar the surface finish of parts or interfere with part seating, mating, or assembly.

What Causes Flashing?

The causes of flash are numerous and include parting line mismatches, improper venting, low clamping pressure, low viscosity, and uneven flow. Some of these problems are related to tooling but others are a function of processing.

- Parting Line Mismatches – Dust, dirt, contaminants, and residues can keep the halves of an injection mold from closing properly. Mold cavities that are worn won’t fit tightly together either. Pressure can also deform the metal surfaces of mold plates, and complex part geometries can complicate closure.

- Improper Venting – Vents that are old and worn may fail to meet required tolerances and allow too much or too little air to escape. Vents that aren’t deep enough may allow stiffer plastics to protrude and vents that aren’t thin enough may allow more fluid materials to pass through.

- Low Clamping Pressure – The pack/hold phase of injection molding ensures that the cavity is completely filled but it can also force the mold open. If the clamping pressure isn’t high enough to resist this force, plastic may leak from the mold even if the mold halves fit tightly together.

- Low Viscosity and Uneven Flow – Processing conditions may cause plastics to flow too readily or fill the mold too rapidly. Examples include melt temperatures that are too high, residence times that are too long, residual moisture from inadequate drying, and the excessive use of coolants.

Flash Prevention and Reduction

Design for manufacturability (DFM) is a key aspect of flash prevention and reduction. For example, plastic injection molding guidelines recommend placing the parting line along the part’s edge rather than on a flat surface to improve the part’s appearance and function. This not only helps to hide the seam, but it also reduces the chances of flash formation.

During the design phase, your part drawing can indicate how much or how little flash you will accept. There are two measurements to consider. Flash extension measures how much it projects from the plastic part along the mold’s parting line. Flash thickness measures perpendicular to the parting line instead. The location of flashing is also important and can tell you when you designed a parting line in the wrong place.

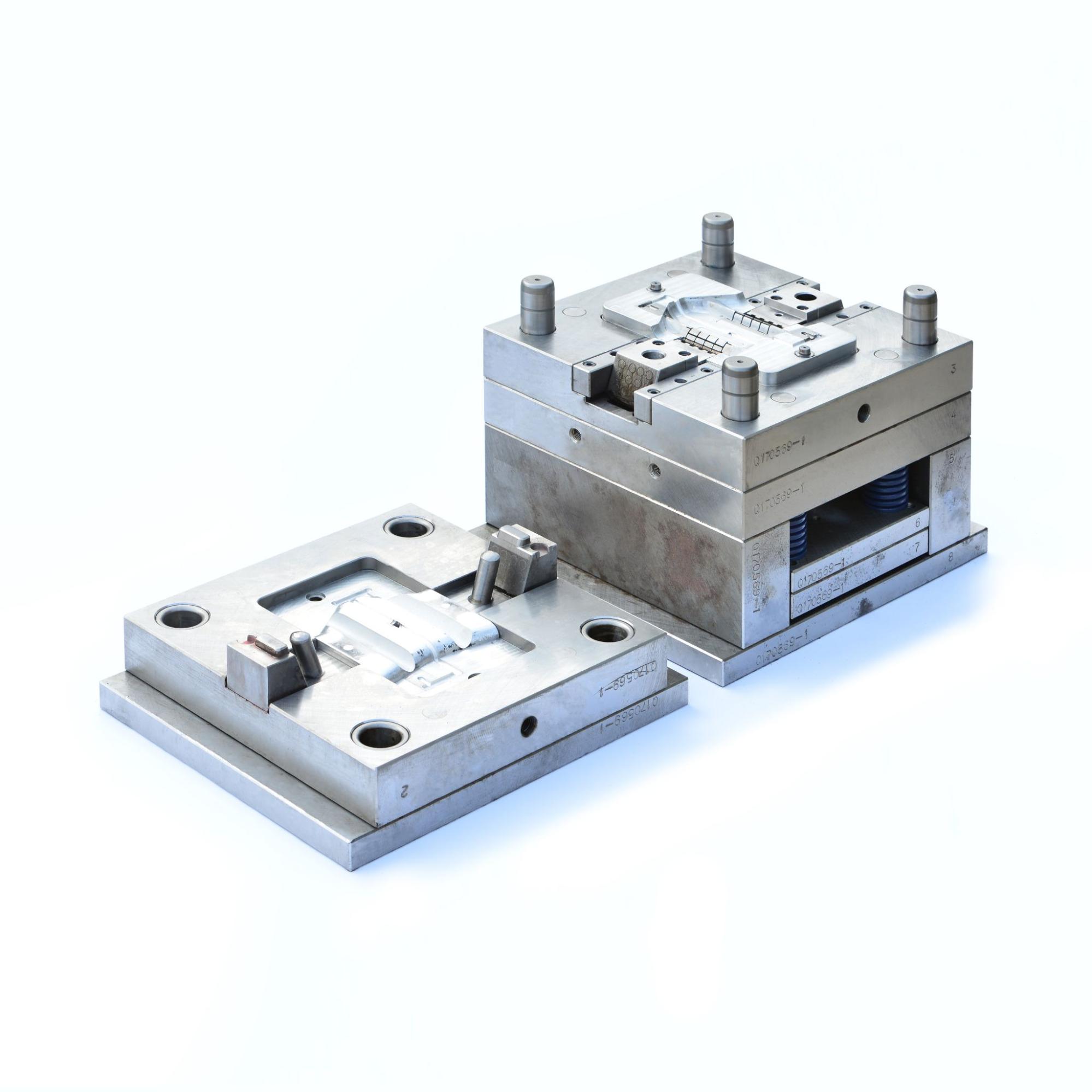

Reducing flash extension and flash thickness improves part quality but increases your mold costs and part costs. If your flash removal requirements are strict, you can specify a flash-less mold so that your plastic parts have only minimal flashing. This type of mold can double or triple your tooling costs, however, so flash removal during post-processing may be more cost-effective.

If your injection molder is using existing tooling, mold maintenance and process improvements can reduce flashing. For example, in the case of parting line mismatches, the solution may be to correct a clamp misalignment, inspect a cavity, or clean mold surfaces. If the clamping tonnage is too low, an injection molder may need to reduce the pack/hold pressure or use a machine with a higher clamping force.

Are You Ready to Fight Flash?

Just as rush hour inevitably means more traffic on the roads, flash is an inescapable part of the injection molding process. However, by reading the signs that there’s a problem up ahead, you can prevent flash from turning into a proverbial traffic jam that costs you time and money. Flash-free tooling means paying more upfront, but the return on investment may be worth it in the end.

If flash-free tooling is too expensive, or if you’re using existing tooling, then the solution could be multifactorial — improving your part design, requesting mold cleaning or maintenance, talking to your injection molder about making process improvements, or using different equipment can all help get you the results you need.

There are plenty of things that can go wrong and increase flashing, but a skilled partner can make things right. That’s why China Manufacturing parts, Inc. is the smart choice for your next plastic injection molding project. We have the resources, know-how, and production network to tackle flashing issues and deliver the quality injection molded parts you need. Create an account and get an instant quote today!