Time to read: 5 min

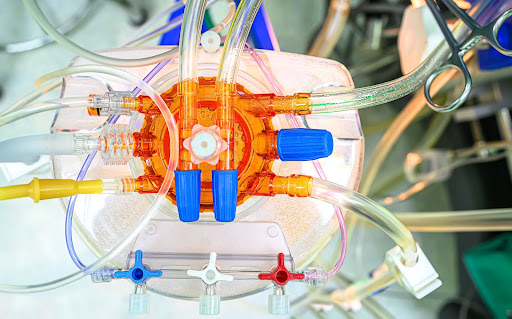

Why is plastic injection molding used to produce many medical products? It’s a proven manufacturing process that supports high-volume production with low per-part costs. Injection molding also supports design and manufacturing complexity with part-to-part integrity. Yet not all medical devices and equipment are injection molded. In fact, there are some medical products that don’t contain plastic at all.

An alternative to plastic injection molding is CNC machining, and when it’s time to select materials to machine, polymers aren’t your only option. For example, metals are used in surgical scalpels, ceramics are used in bone screws, and silicone elastomers are used in everything from wound management to drug delivery. So, why would you use plastic injection molding for the medical product you’re designing?

Learning about the pros and cons of plastic medical injection molding is an important first step in the right direction.

What are the advantages of plastic injection molding for medical products?

There are many reasons to use medical plastic injection molding, but here are the top three.

- High volumes with low per-part costs

- Design and manufacturing complexity

- Wide selection of medical materials

Let’s examine each of these reasons in more detail.

High Volumes with Low Per-Part Costs

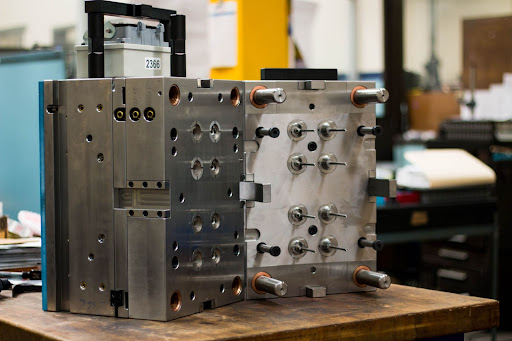

Medical injection molding is typically a high-volume manufacturing process. The cost of a steel mold, or tool, can be expensive, but that cost is spread across many parts. Once you’ve paid for the injection mold, you’ve paid for a major part of your project’s expenses. There are still labor and material costs, but that’s true for any manufacturing process.

Compared to CNC machining, plastic injection molding is significantly faster. With automated equipment and a multi-cavity mold, an injection molder can make many parts simultaneously and with cycle times measured in seconds. Processes like plastic machining take significantly longer and might not be able to produce a large number of parts in the timeframe that you need.

Design and Manufacturing Complexity

Medical injection molding also supports a high level of complexity. For example, plastic injection molding can produce features such as bosses, ribs, holes, threads, custom colors, and textures. Whether you need structural support or aesthetic appeal, injection molders can make medical plastic components that would be difficult or costly to produce with other methods.

Even if your plastic medical component isn’t complex, accuracy and precision matter. Accuracy refers to how close a measurement is to a true value while precision refers to how close measurements of the same item are to each other. With plastic injection molding, you can achieve a high degree of accuracy in the form of tight tolerances. You can also get precision, or part-to-part consistency, across high part volumes.

Wide Selection of Medical Materials

Medical injection molding lets you choose from various materials with different properties, price points, regulatory approvals, and compliance with published standards. Yet, it’s not the sheer number of choices that matters. Instead, it’s the ability to select a material with the specific attributes that you need. For example, a disposable applicator can be made from a commodity plastic that is cost-efficient and impact-resistant.

With some medical products, you may need a more robust, yet also more expensive engineering plastic, a biocompatible material, or an antimicrobial polymer. There are also plastics that can withstand repeated sterilization with steam, radiation, or ethylene oxide (EtO). Material suppliers, such as those in China Manufacturing parts’s Manufacturing Partner ecosystem, offer polymers that are traceable, and you can find medical-grade plastics with FDA approvals.

Compared to metals, plastics are lighter in weight and generally less expensive. Yet, you can still use metal parts (if you need them) with insert molding and overmolding. Both of these plastic injection molding techniques can create bonded assemblies with multiple materials. In the case of overmolding, a softer silicone can be molded over a harder plastic part made of a polymer such as polycarbonate.

Medical plastic injection molding offers plenty of advantages, but that doesn’t mean it’s the right choice for your project. Now that you understand the pros, it’s time to take a look at the cons.

What are the disadvantages of plastic injection molding for medical products?

The downsides of injection molding fall into three major areas:

- High tooling costs

- Design challenges

- Processing issues

Let’s take an in-depth look.

High Tooling Costs

Plastic injection molding always requires tooling. If your production volumes are too low, your return on investment (ROI) could be too long. Plus, medical injection molds can be more expensive because of the importance of part quality. In medical device manufacturing, the difference of a few millimeters or microns can make the difference between a functional component and a plastic part with a quality assurance failure.

If your medical product requires a high degree of precision, you’ll probably need a steel mold with a high-quality finish. While it’s true that plastic injection molding can use less expensive tooling with additive manufacturing produced molds, 3D printed molds support a more limited number of cycles and may lack the accuracy and precision that’s required.

Design Challenges

The cost of your injection mold isn’t the only tool-related consideration. It’s important to design the mold properly and account for variables such as parting line geometry, gating, venting, and finish. There’s also the design of the part itself to consider. When the two halves of the injection mold open, the plastic part needs to eject smoothly. Otherwise, damage to the part could occur.

If you’ve already designed your part and are looking for a manufacturing process, you might need to make some design changes in order to use plastic injection molding. The size of the part matters, too. Because of the higher cost of tool steels, injection molding a larger plastic part could be cost-prohibitive.

Processing Issues

With medical injection molding, issues can arise because of the way that plastics are processed. Even if you design your mold properly, the tool may not fill fully if there are problems with pressure and temperature of the molten plastic. A skilled injection molder can address changes in viscosity, but making constant equipment adjustments increases the potential for part quality issues, longer run times, and higher scrap rates.

Plastic injection molding can be environmentally friendly since some waste materials can be reprocessed. Even the sprues and runners can be reground. Some medical products require virgin plastics, however, and it’s better to avoid waste since regrinding incurs labor costs and extends project timelines. During molding, excessive shrinkage can also occur depending on part thickness. During post-processing, mold flash may need to be removed.

Who can help you weigh the pros and cons of medical plastic injection molding?

Plastic injection molding is used in so many medical products that it might seem like the only option for your application. That’s not necessarily the case, however, so it’s important to choose a partner whose advice you can trust. China Manufacturing parts, Inc. is the smart choice for your next medical manufacturing project and can help you to weigh the pros and cons of injection molding and make the right choice.At China Manufacturing parts, we also have the resources, know-how, and product network to deliver the plastic injection molding products that you need. Learn more about our injection molding services and create an account to get an instant quote today!