Time to read: 5 min

It’s not always easy, but don’t make it harder than it needs to be. Moving from 3D printing to injection molding isn’t as simple as just using your computer-aided design (CAD) file with a different piece of equipment. Because 3D printing offers greater design freedom than injection molding, you may need to modify your CAD file and specify additional information. But let’s not get ahead of ourselves, especially given the time and money involved.

Making the move from 3D printing to injection molding is usually a financial decision that’s based on production volumes. You may also need to consider the timing of expected demand. Preparing your part for injection molding is especially critical, and there are plenty of questions to ask and answer. If you’re a part designer or an engineer who’s looking for help, use this article as a checklist to determine if you’re ready to move from 3D printing to injection molding.

Preparing Your Part Design

If your design isn’t ready for injection molding, it really doesn’t matter how many parts you’d like to mold. Design for manufacturing (DFM) is critical because 3D printing supports part features that are difficult, expensive, or impossible to achieve with injection molding. Some features that aren’t in your 3D printed part can be molded, but with extra costs and longer timelines. Other features, such as lattice-like structures, can be 3D printed but not injection molded.

To assess your injection molding readiness, ask yourself the following questions.

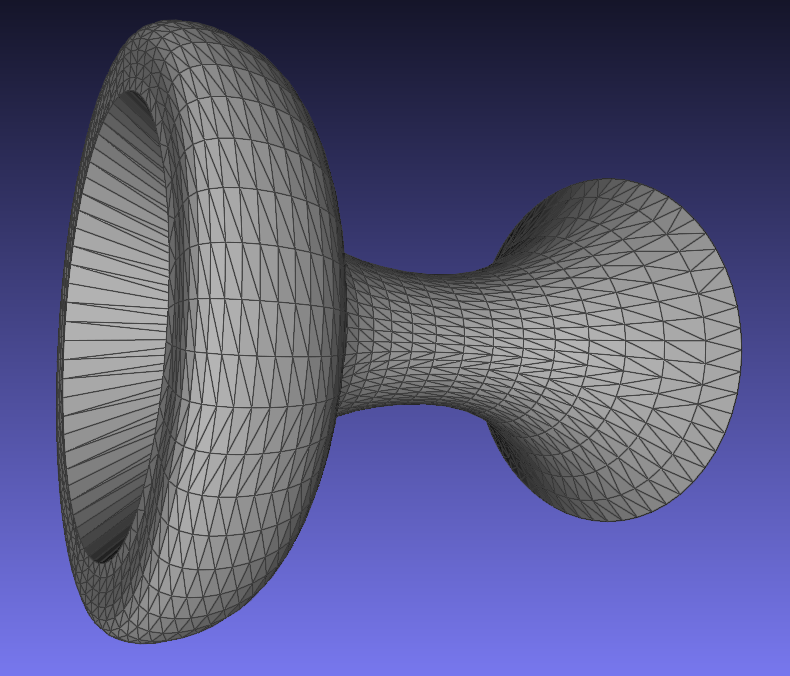

- Are part geometries and surfaces achievable? Injection molding can’t create intricate part geometries and curved surfaces, so the starting point is DFM. If you can’t reduce your part’s complexity or change its shape, consider machining instead of molding. For example, 5-axis CNC machining can achieve intricate geometries with limited setups. CNC lathe turning can create curved surfaces with limited machining time.

- Have you replaced complex infill patterns? Although infill patterns can improve the strength of a 3D printed part, they’re impossible to replicate with injection molding. Instead, use ribs and gussets, features that run perpendicular to a wall or plane.

- Are you using a large enough radii? Otherwise, voids and warpage caused by uneven shrinking may occur. Often, this happens where ribs or gussets meet an adjacent feature or wall. As a rule, the minimum inside radius is the thickness times one. At the corners, however, the inside radius is 0.5 times the material thickness and the outside radius is 1.5 times the material thickness.

- What about wall thickness? Injection molded parts are more sensitive to crater-like sink marks, so keep wall thicknesses relatively uniform. If you need to use both thinner walls and thicker walls, design smooth transitions.

- Did you round sharp corners? They tend to complicate mold release, so it’s better to use fillets instead. The exception is when a corner is also the mold’s parting line.

If you designed your part without injection molding in mind, you’ll also need to answer these questions.

- What are the draft angles? Draft, a small amount of taper, facilitates mold release and helps to avoid part damage. A minimum amount of draft is also needed to achieve a specific surface finish on your mold.

- What about surface finish? Unlike many 3D printed parts, injection molded parts are smooth. The degree of smoothness is a function of how the mold is surface-finished and corresponds to a grade or category that you’ll need to provide.

- What is the allowable flash? Injection molding produces parts with some amount of flash, unwanted material that overflows from the mold cavity. Because flash isn’t an issue in 3D printing, you may need to think about flash location, thickness, and extension for the first time.

- Do you need to adjust part tolerances? Dimensional deviations in 3D printing are greater than in injection molding. Therefore, you could tighten your tolerances. Remember, however, that close-tolerance parts are more expensive.

While finalizing your part design, it’s also important to evaluate materials in terms of your application requirements. That’s because the polymers for 3D printing don’t have identical end-use properties to the plastics for injection molding. For example, 3D printed ABS does not have identical impact resistance to injection molded ABS. That might matter a lot for a body panel, but not so much for a medical device.

Determining the Crossover Volume

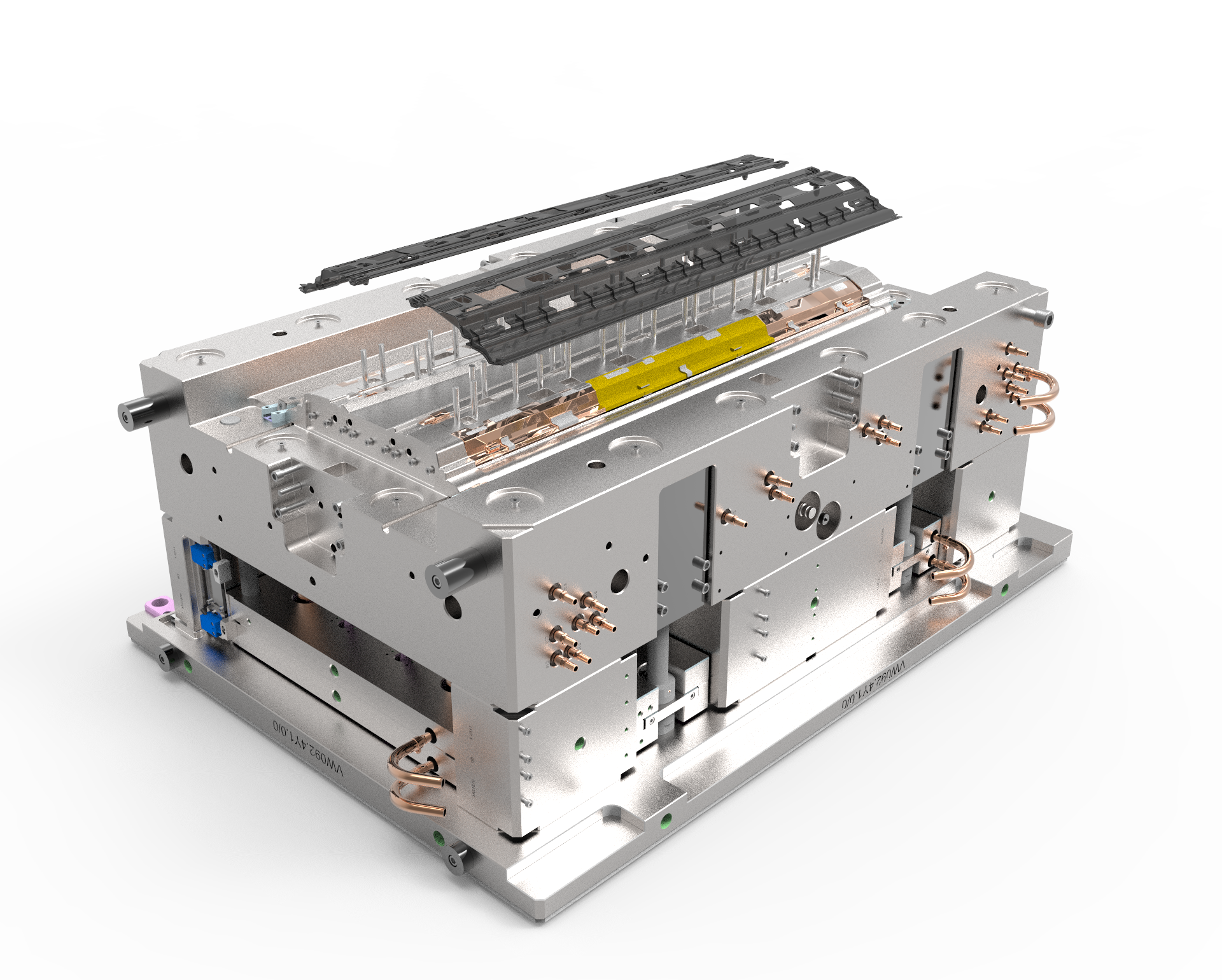

Injection molding often uses machined steel, or “hard”, tooling that can cost from $2,000 to $20,000; however, a large mold can cost much more than that. Still, part size alone doesn’t determine mold costs. The degree of precision that you require also affects the cost, which determines the volume where injection molding becomes cost-effective. You need to evaluate your sales forecast, too. If you don’t expect to sell a high volume of parts, then injection molding may be cost-prohibitive.

Crossover volume is where injection molding makes better financial sense than 3D printing. By spreading the cost of an injection mold across a high volume of parts, you reduce the mold’s per-unit cost and more quickly amortize the cost of tooling. Consider these general guidelines.

- Standard parts have a crossover volume that’s usually in the low thousands.

- Small, high-precision parts have a higher crossover volume because their molds require more complex machining operations. This volume can be in the tens of thousands.

- Large parts also have higher crossover volumes than standard parts. That’s because the mold requires more metal and longer machining times.

Timing matters, too. If you need quick parts for an initial run, waiting weeks for a metal injection mold doesn’t make sense. For a product launch, you’ll need to know when molding can begin. If cost rather than speed is a limiting factor, urethane casting could be a better option since the tooling is significantly less expensive and can support runs up to 500 pieces. You could also use a “soft” injection mold that’s made from aluminum or even a non-metal material and that lasts for a limited number of cycles.

If you need low-cost parts across a high volume of identical units, however, there’s no substitute for injection molding with hard tooling. To determine if you’re really ready to make the move from 3D printing, gather these numbers to find out when you’ll see a return on investment (ROI).

- Total Required Quantity: The number of parts you’ll need for the duration of the project.

- Initial Order Quantity: The number of parts in your first order.

- Annual Order Quantity: The number of parts you’ll need in a given year. For multi-year projects, this number may increase or decrease over time.

Dividing the cost of the mold by the total required quantity gives you the per-unit cost. But how long will it take to produce all of these parts, and will it take years to achieve ROI?

Is Your 3D Printed Part Ready for Injection Molding?

Hopefully after reading this article, you can determine your readiness for moving from 3D printing to injection molding. Economics usually drive this decision, but part designers and engineers also steer this process with part designs that are optimized for injection molding. If you’re ready for an instant injection molding quote, create an account with us to upload your designs. To get more engineering content in your inbox once a month, subscribe our newsletter below!