search

By signing up, you agree to our Terms of Use and Privacy Policy. We may use the info you submit to contact you and use data from third parties to personalize your experience.

Latest

Article

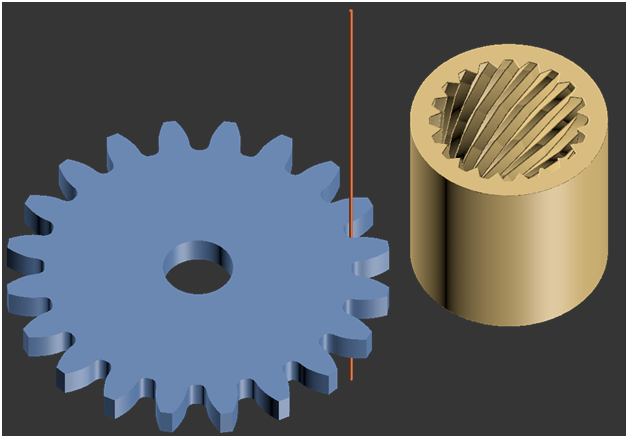

The 3 Essential Methods for Gear Machining

Historically, gear fabrication methods fall into three main categories: generation, forming, and form cutting. As new technologies are developed, there may be new gear machining methods added to the list, but the big three are still the most common ways to make a gear: Gear generation methods use cutting tools in the shape of the […]

Article

EDM: Sparks Fly with This Gear Manufacturing Process

Gears can be fabricated using a myriad of different manufacturing methods. As you may expect, the profile of the teeth needs to follow specific dimensions and constraints in order to transmit torque, prevent slippage and excessive undesired contact stresses. Therefore, the fabrication process you select should accomplish the necessary tolerances and properties. This article will […]

Article

G-code Knowledge is Key to Mastering Any CNC Machine

M06? G54? S1000? Do those numbers mean anything to you? Knowing the most common commands in your G-code may not be at the top of your priority list, but it can go a long way in helping you understand what your machine is doing. CNC machines are really good at doing exactly what they’re told. […]

Article

Casting vs CNC Machining: We’re No Longer in the Bronze Age, But Is It Right for Your Part?

Casting – it’s been around for over 6,000 years and is still widely used today. Advances in casting technology allow the casting of high quality parts with tight tolerances. CNC machining is also pervasive, but much newer. Have you ever considered trying to CNC machine a part that you usually cast? Or are you wondering […]

Article

The Ultimate Guide to Finishing CNC Machined Parts

Welcome to part II of our three-part series about secondary operations. This article covers finishing options, while the others discuss heat treatments and hardware installation. When discussing CNC machining surface finishing options, you may have heard terms like as-machined, anodizing, powder coating, or media blasting. But before we dig into the details of those processes, […]

Article

Checklist: Know When You’re Ready to Go from 3D Printing to Injection Molding

It’s not always easy, but don’t make it harder than it needs to be. Moving from 3D printing to injection molding isn’t as simple as just using your computer-aided design (CAD) file with a different piece of equipment. Because 3D printing offers greater design freedom than injection molding, you may need to modify your CAD […]

Article

Cutting Tools Used in CNC Machining – Choose the Right Tool for the Job

As a mechanical engineer or designer, how much time do you spend thinking about how your parts are going to be machined? Even more specifically, do you know what kinds of tools will be used to make different features or geometries? This article will be your guide to the most common tools used in CNC […]

Article

Introduction to Workholding Options for CNC Machining

Your CNC machining process is only as good as your workholding setup! CNC work holding methods keep your part rigidly in place and reduce the stiffness. You can also refer to work holding as fixturing. A good CNC workholding setup is key for locating the next part to be machined. Fixturing is also important for […]

Article

Precision CNC Machining: How Can You Make Your Parts More Precise?

When you hear precision CNC machining, what do you think about? Isn’t all CNC machining “precision?” In a sense, yes. CNC machining allows you to make a lot of very precise parts relatively quickly. However, it goes much further than that. In this article, we’ll discuss what precision CNC machining is, how you to verify […]

Article

3-Axis to 12-Axis: CNC Milling Machine Capabilities Compared

Computer Numerical Control (or CNC) machining combines the efficiency of computer programming with the accuracy of lathe machines. The programmed software controls the movement of the tools and other machinery, thereby automating the manufacturing process and maintaining design consistency. Modern-day multi-axis CNC Milling Machines come with a wide range of features, which adds value and […]